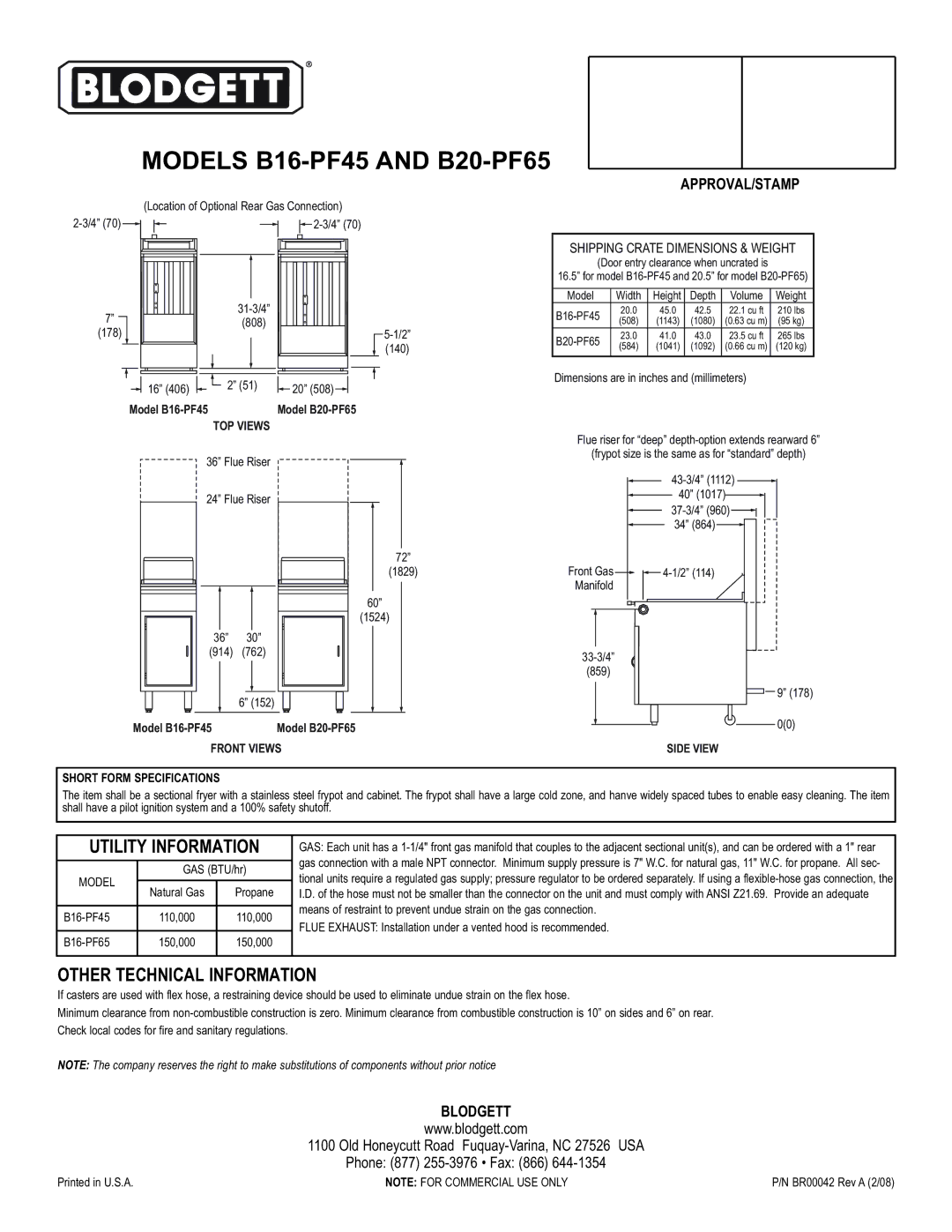

B20-PF65, B16-PF45 specifications

The Blodgett B20-PF65 and B16-PF45 are both remarkable additions to the lineup of commercial convection ovens, designed to meet the diverse needs of the food service industry. These models blend efficiency, innovation, and advanced technology, providing chefs with reliable performance and versatility.The Blodgett B20-PF65 is a perfect choice for establishments demanding high-volume cooking. With a robust capacity, it can accommodate multiple racks, allowing for significant output in a compact design. This oven features a powerful fan system that ensures even heat distribution, resulting in perfectly baked, roasted, or restructured dishes every time. Its precise temperature control is facilitated by a digital control panel, which simplifies the cooking process while minimizing the risk of human error.

One of the standout technologies in the B20-PF65 is the programmable cooking capabilities. Chefs can pre-set cooking times and temperatures, enabling a seamless cooking experience, especially during peak service hours. Additionally, this model incorporates moisture control features, allowing for the retention of essential moisture during the cooking process, which is crucial for baking goods like bread or pastries.

On the other hand, the Blodgett B16-PF45 excels in providing flexible cooking solutions, ideal for smaller kitchens or establishments with moderate volume needs. Despite its smaller size, it doesn’t compromise on performance. The B16-PF45 is built to deliver convection cooking that results in quicker cooking times and energy efficiency.

Both ovens share similar construction qualities, featuring stainless steel exteriors, which not only enhance durability but also make cleaning a breeze. Easy accessibility to the interior components ensures quick maintenance and serviceability, a feature appreciated by busy kitchen staff.

From an energy perspective, both models are designed with efficiency in mind, often incorporating features that reduce energy consumption while maximizing output. This is particularly valuable in today’s environmentally conscious market where sustainability plays a key role.

Overall, the Blodgett B20-PF65 and B16-PF45 convection ovens excel in delivering quality results, cutting-edge technology, and operational efficiency. Whether the requirement is high-volume baking or flexible cooking in a smaller space, these ovens are tailored to enhance performance in any commercial kitchen, making them valuable investments for food service operators.