INFORMATION TO STEAM FITTER

1.Each cooking compartment requires approximately 1 BHP (34.5 lbs of steam per hour) to operate satisfactorily.

2.Assuming availability of 30 psi supply steam pressure immediately to the appliance, then pipe sizes of ½" or 3/4" or 1" will deliver respectively 90, 165 or 385 lbs. of steam per hour to the appliance Heat Exchanger. From the foregoing to use ½" pipe line would most likely prove inadequate.

An extremely important consideration is the pressure drop that will occur through the steam supply line from its point of origin to the appliance. The greater the length of piping and number of valves and elbows, the greater will be the pressure losses.

Consider a pressure drop of 1 (one) psi for each straight length of pipe equivalent to 120 diameters of that pipe. Thus, a 1" pipe having a straight length of 120" (10 feet) is equivalent to 120 diameters of that pipe and will have a pressure loss of 1 psi through that pipe.

Example:

10 p.s.i. Supply Pressure

120 Diameters of 1” pipe Equivalent to 120” (10 ft)

9p.s.i. Available Pressure

Note, in 3/4" pipe size, that a Standard 90º Elbow and Angle Valve and a Globe Valve are equivalent to 1.8 feet, 10 feet and 18 feet respectively of straight pipe.

Similarly, in a 1" pipe size, a standard 90º Elbow and Angle Valve and a Globe Valve are equivalent to 2.2 feet, 12 feet and 23 feet respectively of straight pipe.

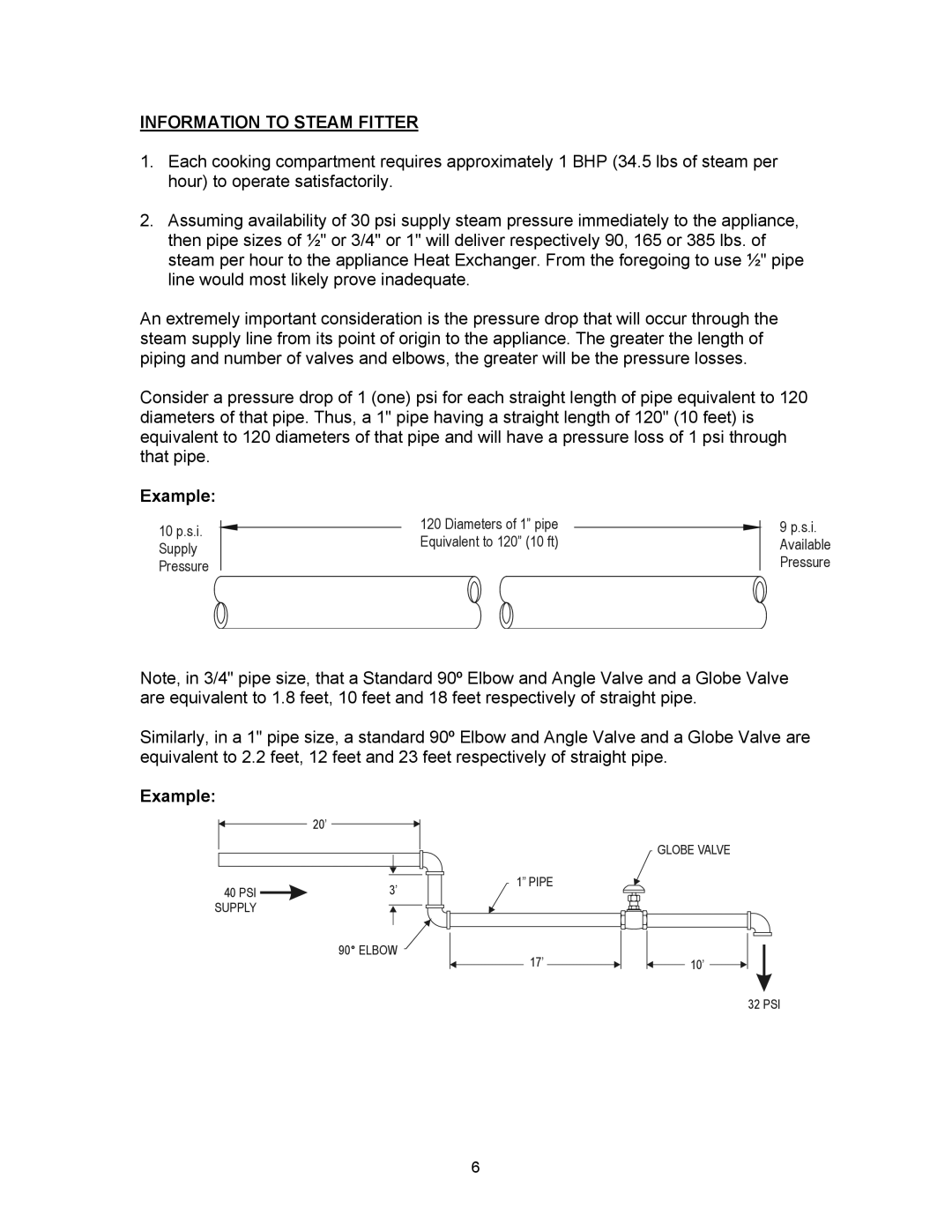

Example:

|

|

| 20’ |

|

| ||

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 PSI |

|

|

|

| 3’ | ||

| |||||||

SUPPLY![]() 90° ELBOW

90° ELBOW ![]()

1” PIPE

17’

GLOBE VALVE

10’

32 PSI

6