(800)

Phone: (805)

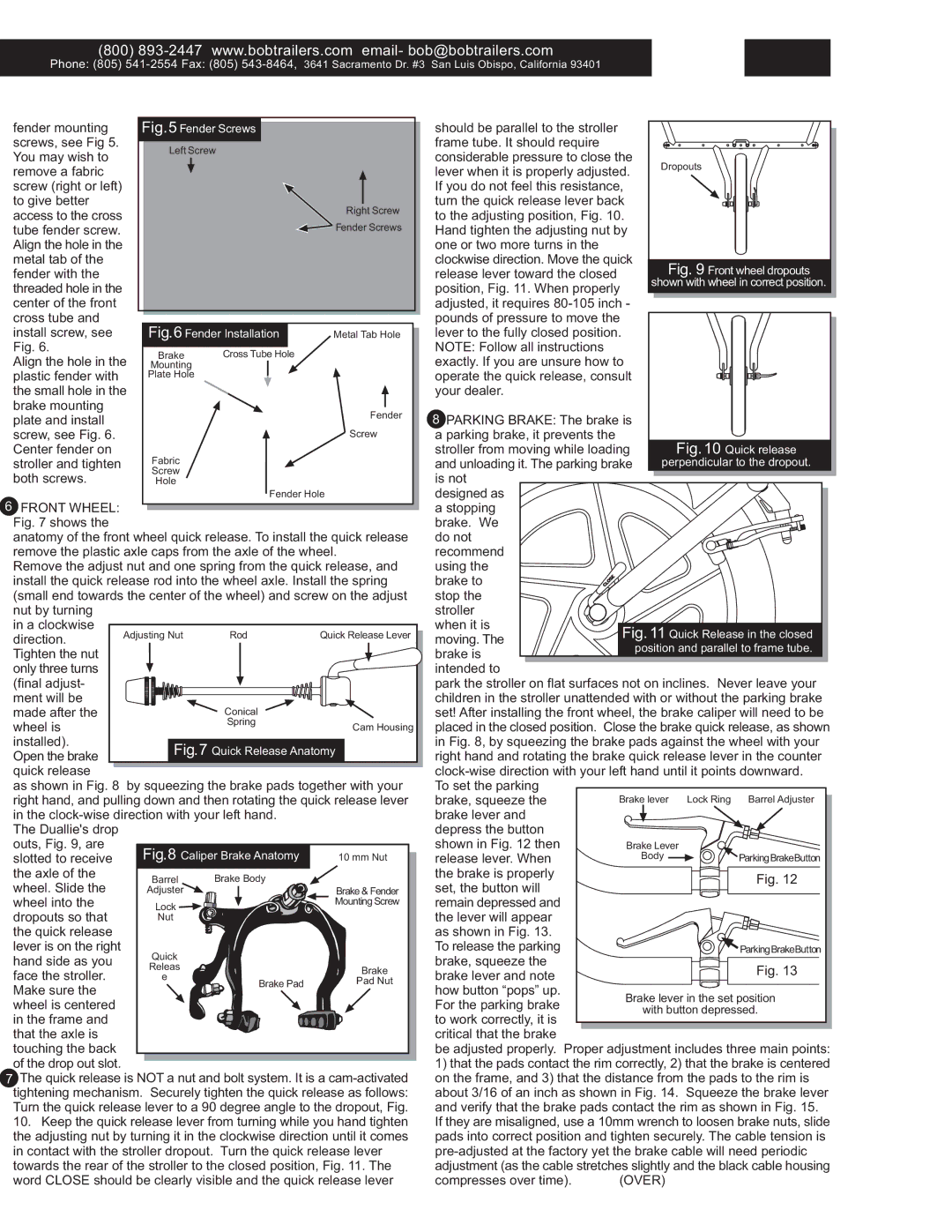

fender mounting | Fig.5 Fender Screws |

|

|

|

|

|

|

| ||

|

|

|

|

| ||||||

screws, see Fig 5. |

|

|

|

|

|

|

|

|

|

|

Left Screw |

|

|

|

|

|

|

|

| ||

You may wish to |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

remove a fabric |

|

|

|

|

|

|

|

|

|

|

screw (right or left) |

|

|

|

|

|

|

|

|

|

|

to give better |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Right Screw |

| |||

access to the cross |

|

|

|

|

|

|

| |||

|

|

|

|

|

| Fender Screws |

| |||

tube fender screw. |

|

|

|

|

|

|

| |||

Align the hole in the |

|

|

|

|

|

|

|

|

|

|

metal tab of the |

|

|

|

|

|

|

|

|

|

|

fender with the |

|

|

|

|

|

|

|

|

|

|

threaded hole in the |

|

|

|

|

|

|

|

|

|

|

center of the front |

|

|

|

|

|

|

|

|

|

|

cross tube and |

|

|

|

|

|

|

|

|

|

|

install screw, see | Fig.6 Fender Installation |

| Metal Tab Hole |

| ||||||

Fig. 6. |

|

|

|

|

|

|

|

|

|

|

Brake | Cross Tube Hole |

|

|

|

| |||||

Align the hole in the |

|

|

|

| ||||||

Mounting |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |||

plastic fender with | Plate Hole |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |||

the small hole in the |

|

|

|

|

|

|

|

|

|

|

brake mounting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Fender |

| ||

plate and install |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

screw, see Fig. 6. |

|

|

|

|

|

| Screw |

| ||

Center fender on | Fabric |

|

|

|

|

|

|

|

| |

stroller and tighten |

|

|

|

|

|

|

|

| ||

both screws. | Screw |

|

|

|

|

|

|

|

| |

Hole |

|

|

|

|

|

|

|

| ||

|

|

|

|

| Fender Hole |

|

|

|

| |

6FRONT WHEEL: Fig. 7 shows the

anatomy of the front wheel quick release. To install the quick release remove the plastic axle caps from the axle of the wheel.

Remove the adjust nut and one spring from the quick release, and install the quick release rod into the wheel axle. Install the spring (small end towards the center of the wheel) and screw on the adjust nut by turning

in a clockwise direction.

Tighten the nut only three turns

(final adjust- ment will be

made after the wheel is

installed). Open the brake quick release

as shown in Fig. 8 by squeezing the brake pads together with your right hand, and pulling down and then rotating the quick release lever in the

The Duallie's drop outs, Fig. 9, are slotted to receive the axle of the

wheel. Slide the wheel into the dropouts so that the quick release

lever is on the right hand side as you

face the stroller. Make sure the

wheel is centered

in the frame and that the axle is touching the back

of the drop out slot.

7The quick release is NOT a nut and bolt system. It is a

should be parallel to the stroller frame tube. It should require considerable pressure to close the lever when it is properly adjusted. If you do not feel this resistance, turn the quick release lever back to the adjusting position, Fig. 10. Hand tighten the adjusting nut by one or two more turns in the clockwise direction. Move the quick release lever toward the closed position, Fig. 11. When properly adjusted, it requires

8PARKING BRAKE: The brake is a parking brake, it prevents the

stroller from moving while loading and unloading it. The parking brake is not

designed as

astopping brake. We do not recommend using the brake to stop the stroller

when it is moving. The brake is intended to

park the stroller on flat surfaces not on inclines. Never leave your children in the stroller unattended with or without the parking brake set! After installing the front wheel, the brake caliper will need to be placed in the closed position. Close the brake quick release, as shown in Fig. 8, by squeezing the brake pads against the wheel with your right hand and rotating the brake quick release lever in the counter

To set the parking brake, squeeze the brake lever and

depress the button shown in Fig. 12 then release lever. When the brake is properly

set, the button will remain depressed and the lever will appear

as shown in Fig. 13.

To release the parking brake, squeeze the

brake lever and note

how button “pops” up. For the parking brake

to work correctly, it is critical that the brake

be adjusted properly. Proper adjustment includes three main points:

1)that the pads contact the rim correctly, 2) that the brake is centered on the frame, and 3) that the distance from the pads to the rim is about 3/16 of an inch as shown in Fig. 14. Squeeze the brake lever and verify that the brake pads contact the rim as shown in Fig. 15. If they are misaligned, use a 10mm wrench to loosen brake nuts, slide pads into correct position and tighten securely. The cable tension is

compresses over time). | (OVER) |