BM 2610967913 9/03 9/26/03 4:56 PM Page 9

the tool with the belt in contact with the work surface). Place the heel of the sander on the work first. Then, with a forward motion, begin the sanding stroke as the machine is lowered onto the work surface. This will prevent gouging. Keep the sander moving so that your work will be smooth and even. The stroke is simply a

WOOD FINISHING

Take care to select belts wisely. For initial smoothing of rough lumber, use coarse or very coarse grit and sand with the grain. On very uneven or hard wood, sand diagonally (across the grain). Be careful to avoid gouging. Now switch to medium grit belt and sand with the grain. This will provide a relatively level and smooth finish. Now insert a fine grit belt for final finishing. Always sand with the grain to remove scratches left by coarser belts. Keep the sander moving in long, light strokes during finishing operations. As a final touch, experienced sanders will often insert a “used” fine belt to provide a smooth surface for filling, sealing, brushing or spraying.

REFINISHING COATED WOOD

Your belt sander will also help remove old paint, varnish or lacquer; however, if the coating consists of several layers, remove as much as possible with a paint solvent or varnish remover before using the belt sander. Use a hand scraper to remove the residue left by the solvent and allow surface to dry completely before sanding.

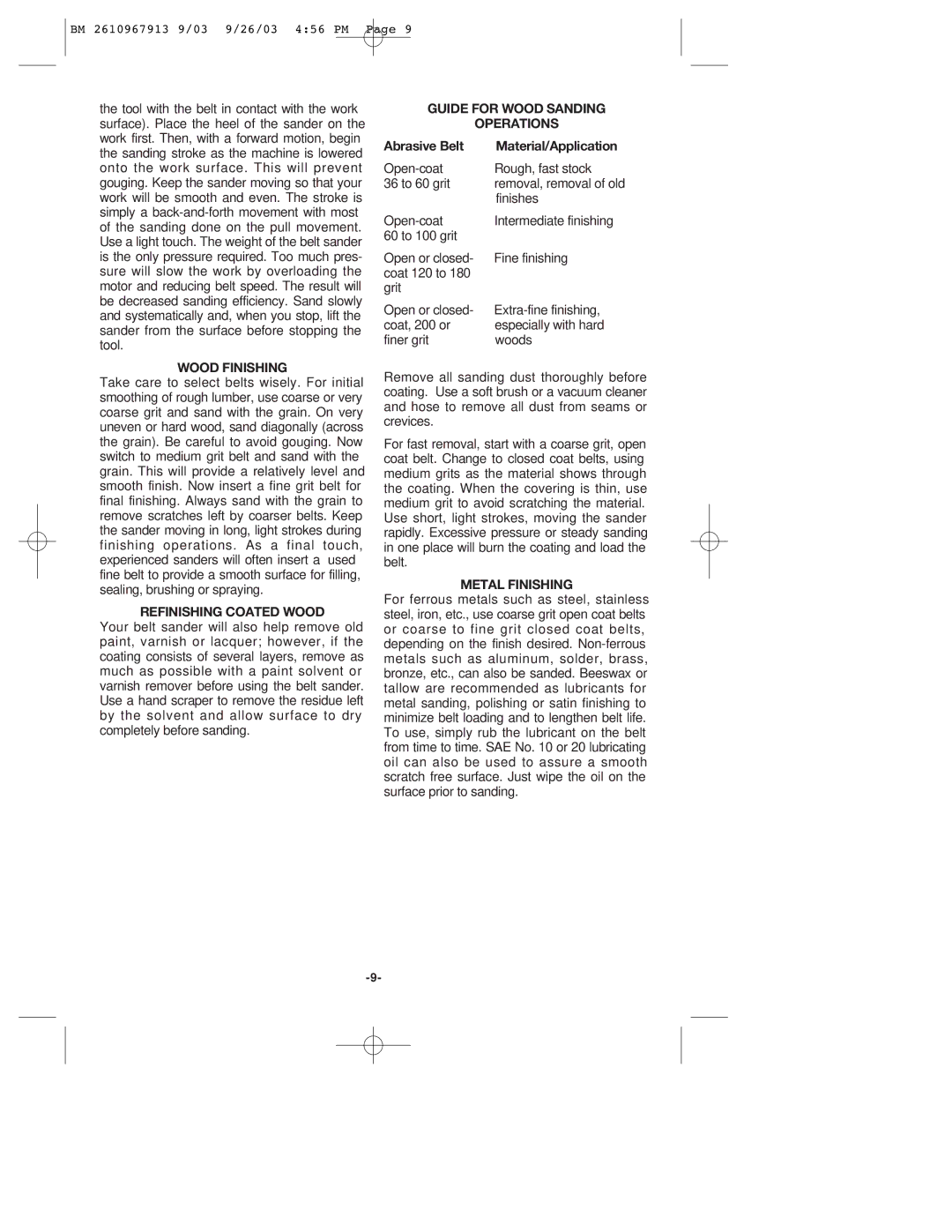

GUIDE FOR WOOD SANDING

OPERATIONS

Abrasive Belt | Material/Application |

Rough, fast stock | |

36 to 60 grit | removal, removal of old |

| finishes |

Intermediate finishing | |

60 to 100 grit |

|

Open or closed- | Fine finishing |

coat 120 to 180 |

|

grit |

|

Open or closed- | |

coat, 200 or | especially with hard |

finer grit | woods |

Remove all sanding dust thoroughly before coating. Use a soft brush or a vacuum cleaner and hose to remove all dust from seams or crevices.

For fast removal, start with a coarse grit, open coat belt. Change to closed coat belts, using medium grits as the material shows through the coating. When the covering is thin, use medium grit to avoid scratching the material. Use short, light strokes, moving the sander rapidly. Excessive pressure or steady sanding in one place will burn the coating and load the belt.

METAL FINISHING

For ferrous metals such as steel, stainless steel, iron, etc., use coarse grit open coat belts or coarse to fine grit closed coat belts, depending on the finish desired.