BM 2609931769

BM 2609931769 07-11:BM 2609931769 07-11.qxp 7/13/11 8:42 AM Page 10

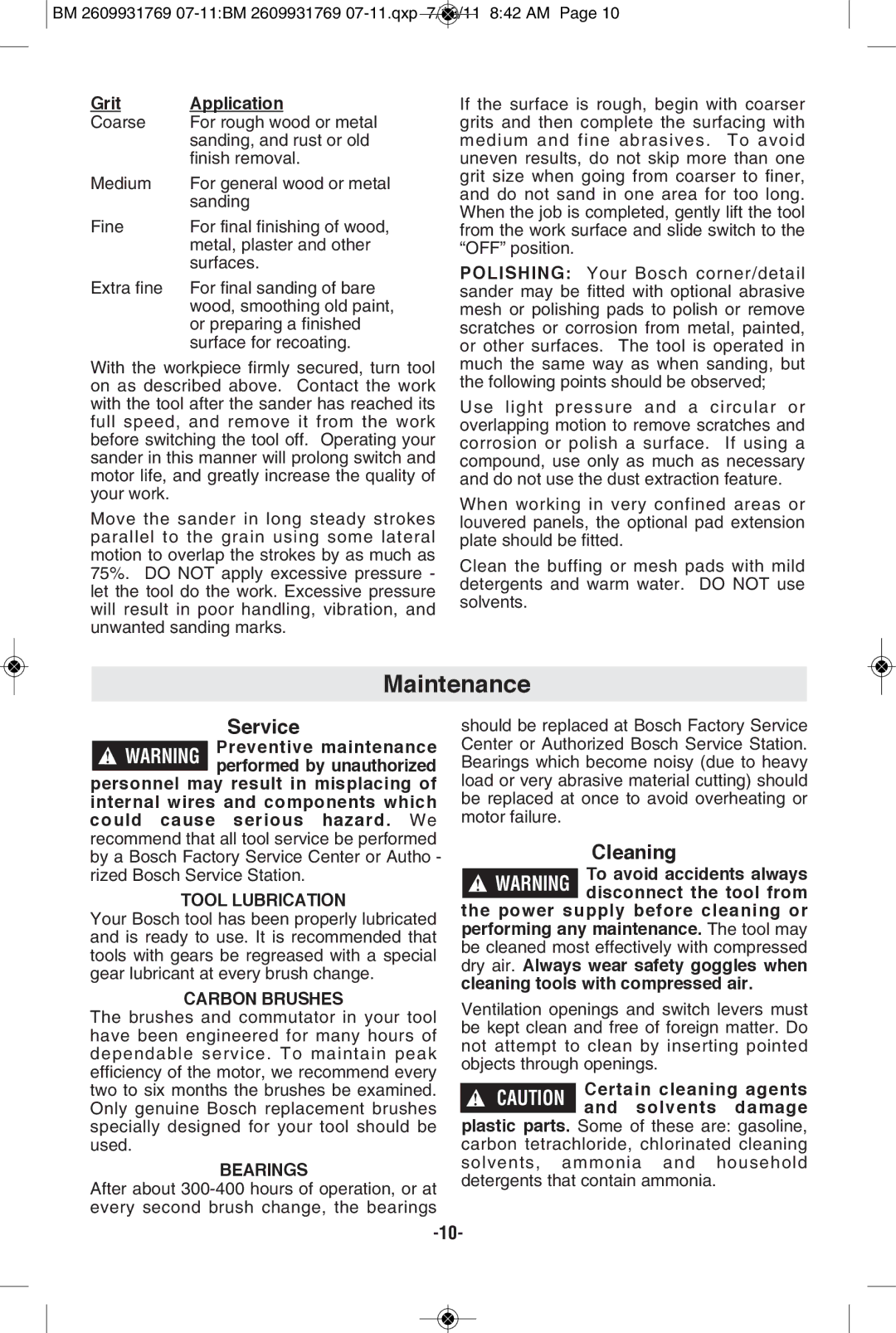

Grit | Application |

Coarse | For rough wood or metal |

| sanding, and rust or old |

| finish removal. |

Medium | For general wood or metal |

| sanding |

Fine | For final finishing of wood, |

| metal, plaster and other |

| surfaces. |

Extra fine | For final sanding of bare |

| wood, smoothing old paint, |

| or preparing a finished |

| surface for recoating. |

With the workpiece firmly secured, turn tool on as described above. Contact the work with the tool after the sander has reached its full speed, and remove it from the work before switching the tool off. Operating your sander in this manner will prolong switch and motor life, and greatly increase the quality of your work.

Move the sander in long steady strokes parallel to the grain using some lateral motion to overlap the strokes by as much as 75%. DO NOT apply excessive pressure - let the tool do the work. Excessive pressure will result in poor handling, vibration, and unwanted sanding marks.

If the surface is rough, begin with coarser grits and then complete the surfacing with medium and fine abrasives. To avoid uneven results, do not skip more than one grit size when going from coarser to finer, and do not sand in one area for too long. When the job is completed, gently lift the tool from the work surface and slide switch to the “OFF” position.

POLISHING: Your Bosch corner/detail sander may be fitted with optional abrasive mesh or polishing pads to polish or remove scratches or corrosion from metal, painted, or other surfaces. The tool is operated in much the same way as when sanding, but the following points should be observed;

Use light pressure and a circular or overlapping motion to remove scratches and corrosion or polish a surface. If using a compound, use only as much as necessary and do not use the dust extraction feature.

When working in very confined areas or louvered panels, the optional pad extension plate should be fitted.

Clean the buffing or mesh pads with mild detergents and warm water. DO NOT use solvents.

Maintenance

Service

Preventive maintenance

!WARNING performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch Factory Service Center or Autho - rized Bosch Service Station.

TOOL LUbRICATION

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

CARbON bRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brushes be examined. Only genuine Bosch replacement brushes specially designed for your tool should be used.

bEARINGS

After about

should be replaced at Bosch Factory Service Center or Authorized Bosch Service Station. Bearings which become noisy (due to heavy load or very abrasive material cutting) should be replaced at once to avoid overheating or motor failure.

Cleaning

To avoid accidents always disconnect the tool from the power supply before cleaning or

performing any maintenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

Certain cleaning agents ! CAUTION and solvents damage

plastic parts. Some of these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.