BM 2610914126 9-03 10/1/03 10:31 AM Page 8

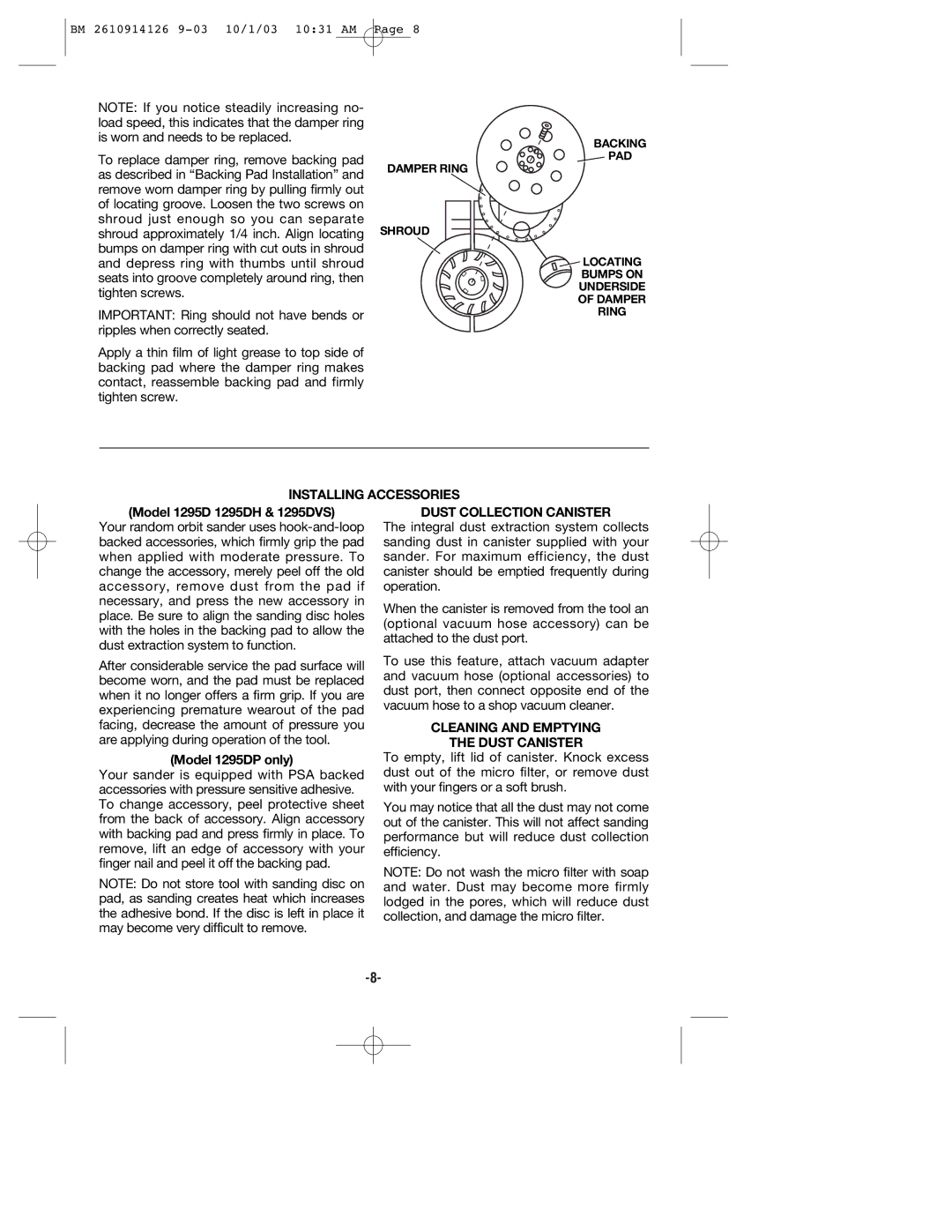

NOTE: If you notice steadily increasing no- load speed, this indicates that the damper ring is worn and needs to be replaced.

To replace damper ring, remove backing pad as described in “Backing Pad Installation” and remove worn damper ring by pulling firmly out of locating groove. Loosen the two screws on shroud just enough so you can separate shroud approximately 1/4 inch. Align locating bumps on damper ring with cut outs in shroud and depress ring with thumbs until shroud seats into groove completely around ring, then tighten screws.

IMPORTANT: Ring should not have bends or ripples when correctly seated.

Apply a thin film of light grease to top side of backing pad where the damper ring makes contact, reassemble backing pad and firmly tighten screw.

DAMPER RING

SHROUD

BACKING

PAD

![]() LOCATING BUMPS ON UNDERSIDE OF DAMPER

LOCATING BUMPS ON UNDERSIDE OF DAMPER

RING

INSTALLING ACCESSORIES

(Model 1295D 1295DH & 1295DVS)

Your random orbit sander uses

After considerable service the pad surface will become worn, and the pad must be replaced when it no longer offers a firm grip. If you are experiencing premature wearout of the pad facing, decrease the amount of pressure you are applying during operation of the tool.

(Model 1295DP only)

Your sander is equipped with PSA backed accessories with pressure sensitive adhesive. To change accessory, peel protective sheet from the back of accessory. Align accessory with backing pad and press firmly in place. To remove, lift an edge of accessory with your finger nail and peel it off the backing pad.

NOTE: Do not store tool with sanding disc on pad, as sanding creates heat which increases the adhesive bond. If the disc is left in place it may become very difficult to remove.

DUST COLLECTION CANISTER

The integral dust extraction system collects sanding dust in canister supplied with your sander. For maximum efficiency, the dust canister should be emptied frequently during operation.

When the canister is removed from the tool an (optional vacuum hose accessory) can be attached to the dust port.

To use this feature, attach vacuum adapter and vacuum hose (optional accessories) to dust port, then connect opposite end of the vacuum hose to a shop vacuum cleaner.

CLEANING AND EMPTYING

THE DUST CANISTER

To empty, lift lid of canister. Knock excess dust out of the micro filter, or remove dust with your fingers or a soft brush.

You may notice that all the dust may not come out of the canister. This will not affect sanding performance but will reduce dust collection efficiency.

NOTE: Do not wash the micro filter with soap and water. Dust may become more firmly lodged in the pores, which will reduce dust collection, and damage the micro filter.