BM 2610925947

Operating Instructions

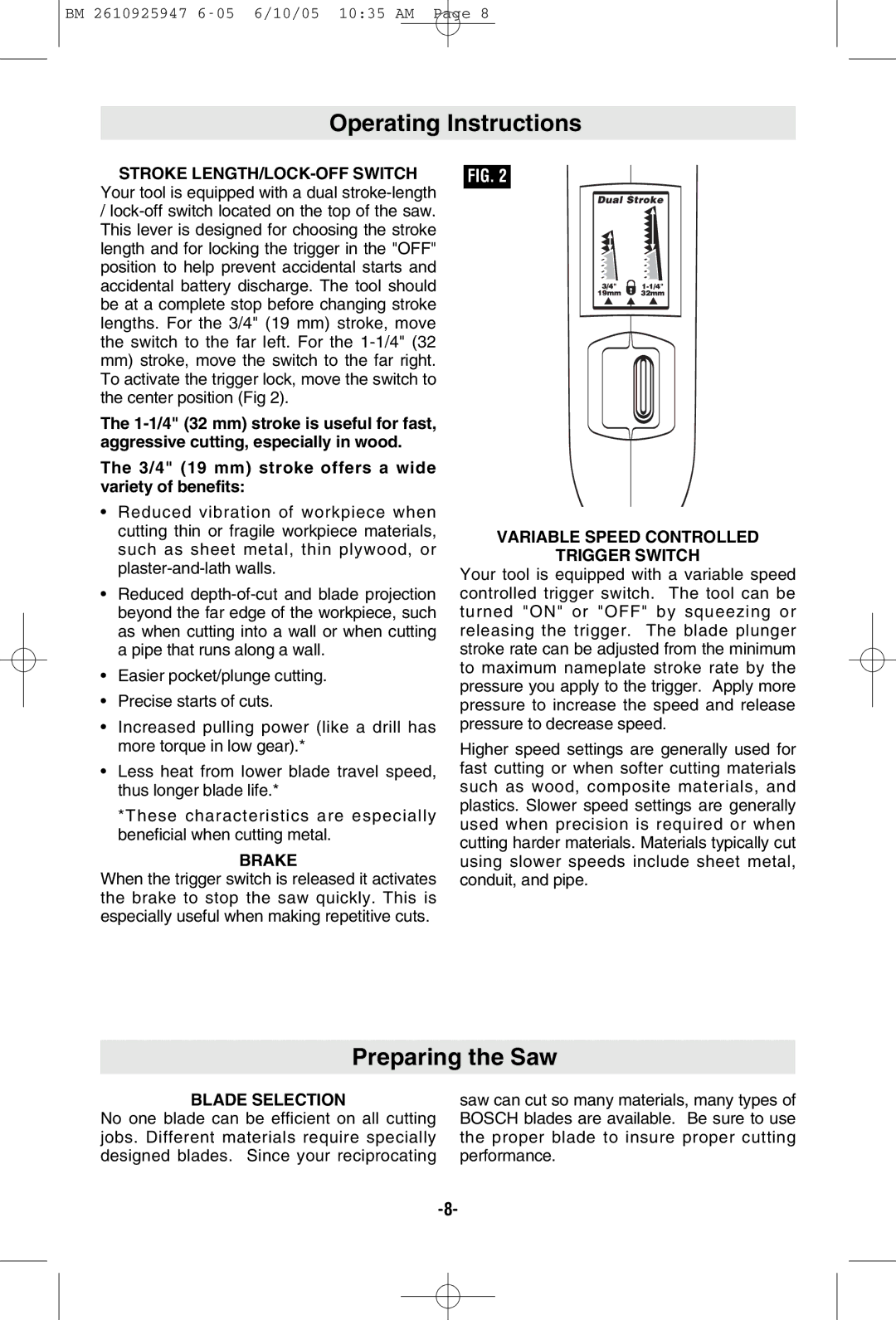

STROKE LENGTH/LOCK-OFF SWITCH

Your tool is equipped with a dual

/

The

The 3/4" (19 mm) stroke offers a wide variety of benefits:

•Reduced vibration of workpiece when cutting thin or fragile workpiece materials, such as sheet metal, thin plywood, or

•Reduced

•Easier pocket/plunge cutting.

•Precise starts of cuts.

•Increased pulling power (like a drill has more torque in low gear).*

•Less heat from lower blade travel speed, thus longer blade life.*

*These characteristics are especially beneficial when cutting metal.

BRAKE

When the trigger switch is released it activates the brake to stop the saw quickly. This is especially useful when making repetitive cuts.

FIG. 2

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed controlled trigger switch. The tool can be turned "ON" or "OFF" by squeezing or releasing the trigger. The blade plunger stroke rate can be adjusted from the minimum to maximum nameplate stroke rate by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed.

Higher speed settings are generally used for fast cutting or when softer cutting materials such as wood, composite materials, and plastics. Slower speed settings are generally used when precision is required or when cutting harder materials. Materials typically cut using slower speeds include sheet metal, conduit, and pipe.

Preparing the Saw

BLADE SELECTION

No one blade can be efficient on all cutting jobs. Different materials require specially designed blades. Since your reciprocating

saw can cut so many materials, many types of BOSCH blades are available. Be sure to use the proper blade to insure proper cutting performance.