BM 2610925947

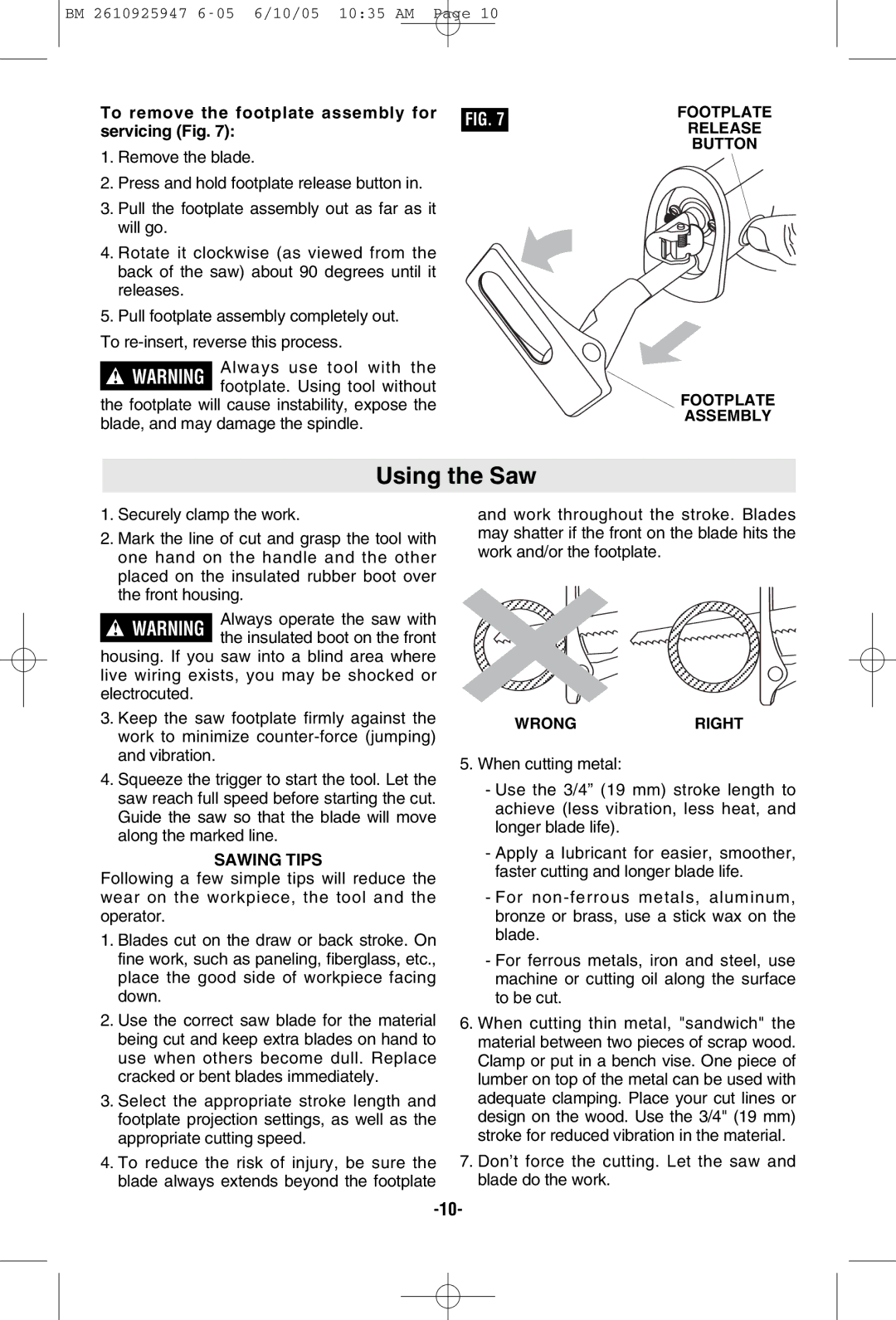

To remove the footplate assembly for | FIG. 7 | FOOTPLATE | ||

servicing (Fig. 7): | RELEASE | |||

| ||||

1. Remove the blade. |

| BUTTON | ||

|

| |||

2. | Press and hold footplate release button in. |

|

| |

3. | Pull the footplate assembly out as far as it |

|

| |

| will go. |

|

| |

4. Rotate it clockwise (as viewed from the |

|

| ||

| back of the saw) about 90 degrees until it |

|

| |

| releases. |

|

| |

5. | Pull footplate assembly completely out. |

|

| |

To

! WARNING | Always use tool with the |

|

footplate. Using tool without |

| |

| FOOTPLATE | |

the footplate will cause instability, expose the | ||

blade, and may damage the spindle. | ASSEMBLY | |

| ||

Using the Saw

1.Securely clamp the work.

2.Mark the line of cut and grasp the tool with one hand on the handle and the other placed on the insulated rubber boot over the front housing.

Always operate the saw with ! WARNING the insulated boot on the front

housing. If you saw into a blind area where live wiring exists, you may be shocked or electrocuted.

3.Keep the saw footplate firmly against the work to minimize

4.Squeeze the trigger to start the tool. Let the saw reach full speed before starting the cut. Guide the saw so that the blade will move along the marked line.

SAWING TIPS

Following a few simple tips will reduce the wear on the workpiece, the tool and the operator.

1.Blades cut on the draw or back stroke. On fine work, such as paneling, fiberglass, etc., place the good side of workpiece facing down.

2.Use the correct saw blade for the material being cut and keep extra blades on hand to use when others become dull. Replace cracked or bent blades immediately.

3.Select the appropriate stroke length and footplate projection settings, as well as the appropriate cutting speed.

4.To reduce the risk of injury, be sure the blade always extends beyond the footplate

and work throughout the stroke. Blades may shatter if the front on the blade hits the work and/or the footplate.

WRONGRIGHT

5.When cutting metal:

-Use the 3/4” (19 mm) stroke length to achieve (less vibration, less heat, and longer blade life).

-Apply a lubricant for easier, smoother, faster cutting and longer blade life.

-For

-For ferrous metals, iron and steel, use machine or cutting oil along the surface to be cut.

6.When cutting thin metal, "sandwich" the material between two pieces of scrap wood. Clamp or put in a bench vise. One piece of lumber on top of the metal can be used with adequate clamping. Place your cut lines or design on the wood. Use the 3/4" (19 mm) stroke for reduced vibration in the material.

7.Don’t force the cutting. Let the saw and blade do the work.