BM 1609929C33 10/03 10/28/03 2:49 PM Page 11

SANDING WOOD

When sanding wood the direction of the disc motion at the contact point should parallel the grain as much as possible. The rapid cut of discs and the swirl type scratch pattern they occasionally create generally prohibit their use for producing the final finish.

Scratches and circular marks are usually the result of using too coarse a grit. When changing to a finer grit, move across the sanding lines that were made by a previous coarser disc.

SANDING METAL

When sanding automobiles or appliances, wipe the metal clean with a

For heavy duty work, use a coarse grit disc first.

Wire Brush Operations

Wire brushes are intended to “clean” structural steel, castings, sheet metal, stone and concrete. They are used to remove rust, scale and paint.

!WARNING Avoid bouncing and snagging the wire brush, especially

when working corners, sharp edges etc. This can cause loss of control and

BRUSHING PRESSURE

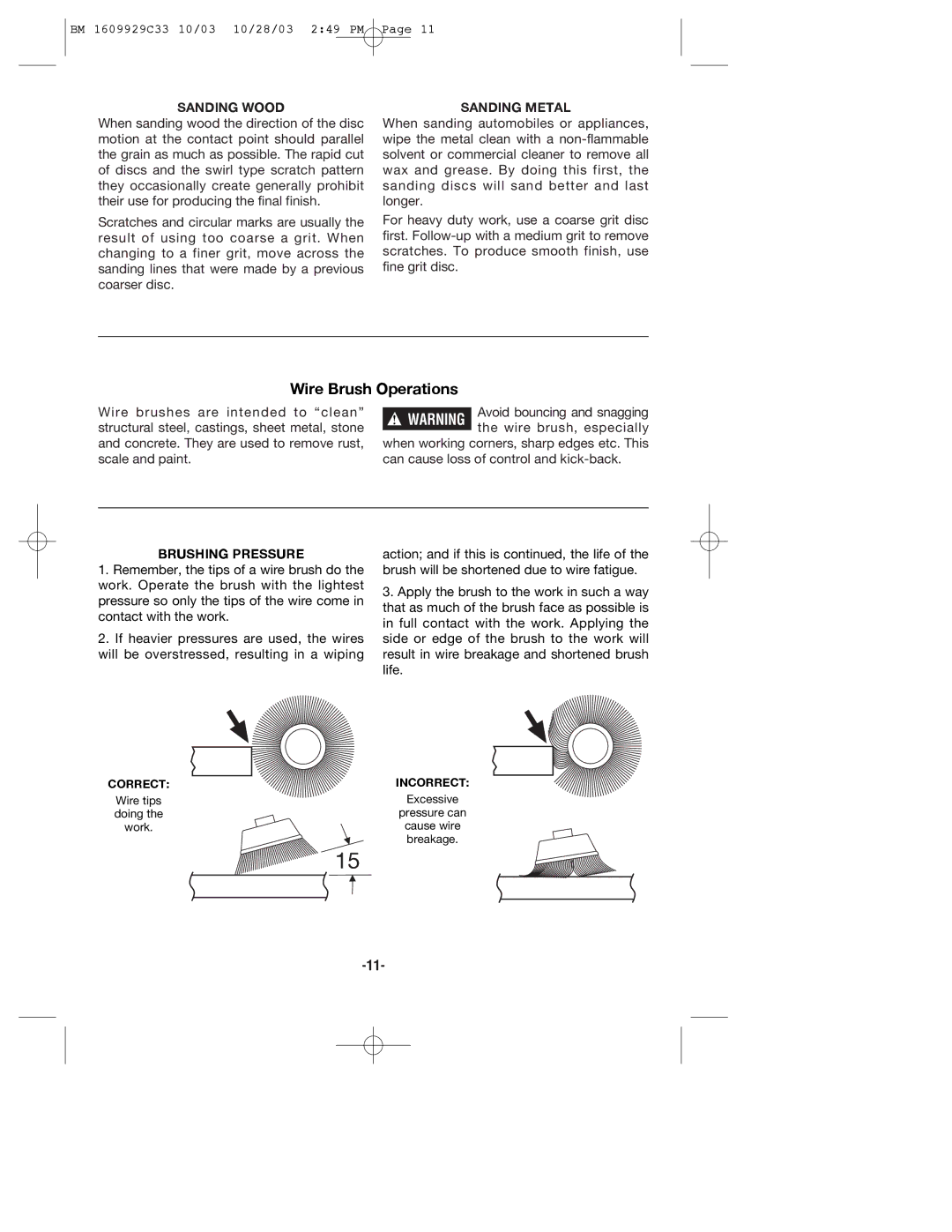

1.Remember, the tips of a wire brush do the work. Operate the brush with the lightest pressure so only the tips of the wire come in contact with the work.

2.If heavier pressures are used, the wires will be overstressed, resulting in a wiping

action; and if this is continued, the life of the brush will be shortened due to wire fatigue.

3.Apply the brush to the work in such a way that as much of the brush face as possible is in full contact with the work. Applying the side or edge of the brush to the work will result in wire breakage and shortened brush life.

CORRECT: | INCORRECT: |

Wire tips | Excessive |

doing the | pressure can |

work. | cause wire |

| breakage. |

15°