BM 3609929777 1/02 1/3/02 1:16 PM Page 9

Hold the tool with both hands and apply the diamond wheel flat on the work surface, advancing the tool moderately back and forth.

When removing coatings from work surfaces, hold the tool at a slight angle to the workpriece surface. Holding the tool at a slight angle will not reduce the effect of the dust extraction.

The dry diamond cup wheel included with the tool is intended for hard materials.

A dull dry diamond cup wheel can be sharpened with a abrasive material (e.g., chalky sand stone).

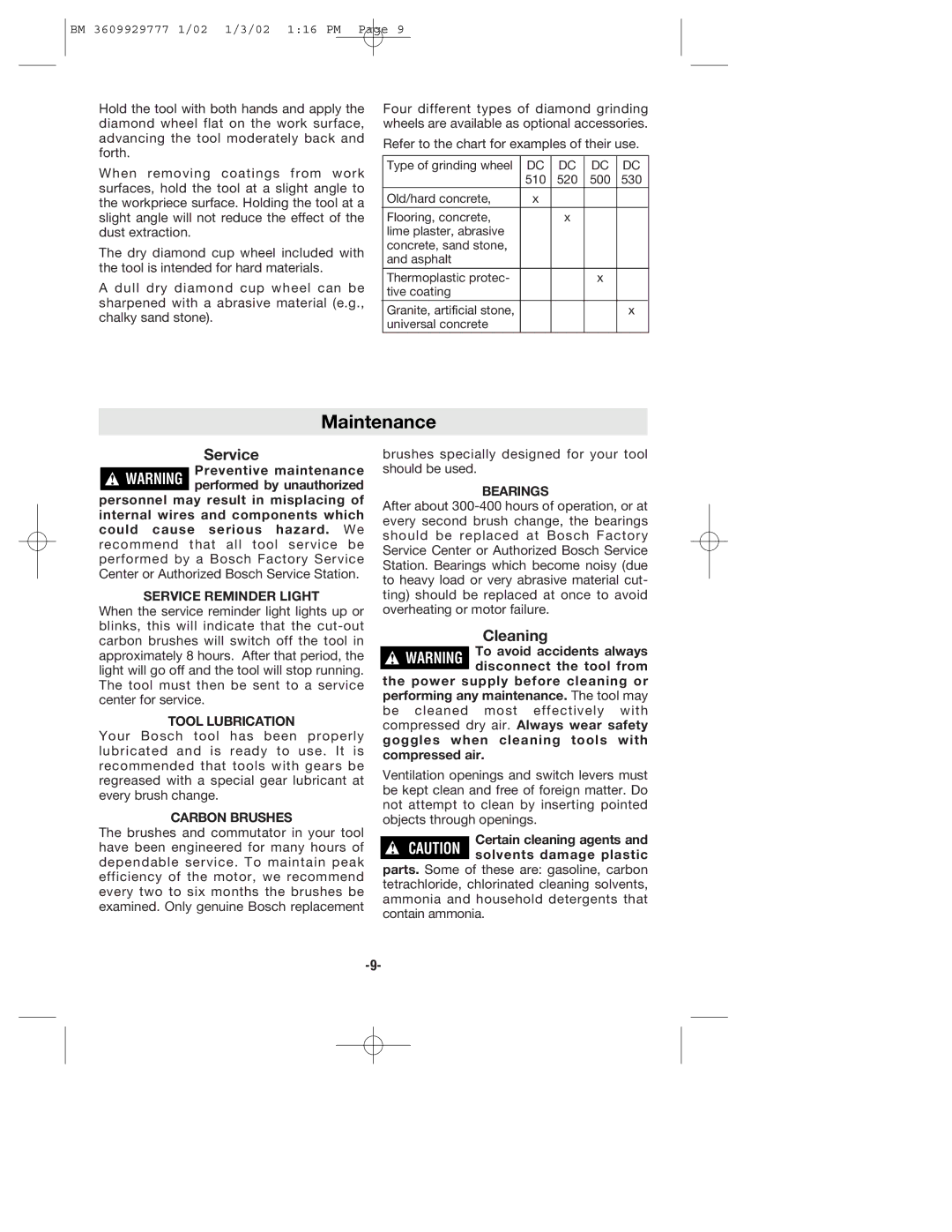

Four different types of diamond grinding wheels are available as optional accessories.

Refer to the chart for examples of their use.

Type of grinding wheel | DC | DC | DC | DC |

| 510 | 520 | 500 | 530 |

Old/hard concrete, | x |

|

|

|

Flooring, concrete, |

| x |

|

|

lime plaster, abrasive |

|

|

|

|

concrete, sand stone, |

|

|

|

|

and asphalt |

|

|

|

|

|

|

|

|

|

Thermoplastic protec- |

|

| x |

|

tive coating |

|

|

|

|

Granite, artificial stone, |

|

|

| x |

universal concrete |

|

|

|

|

Maintenance

Service

Preventive maintenance

!WARNING performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch Factory Service Center or Authorized Bosch Service Station.

SERVICE REMINDER LIGHT

When the service reminder light lights up or blinks, this will indicate that the

TOOL LUBRICATION

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brushes be examined. Only genuine Bosch replacement

brushes specially designed for your tool should be used.

BEARINGS

After about

Cleaning

!WARNING To avoid accidents always disconnect the tool from

the power supply before cleaning or performing any maintenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.