BM 3609929818 3/03 3/10/03 8:42 AM Page 10

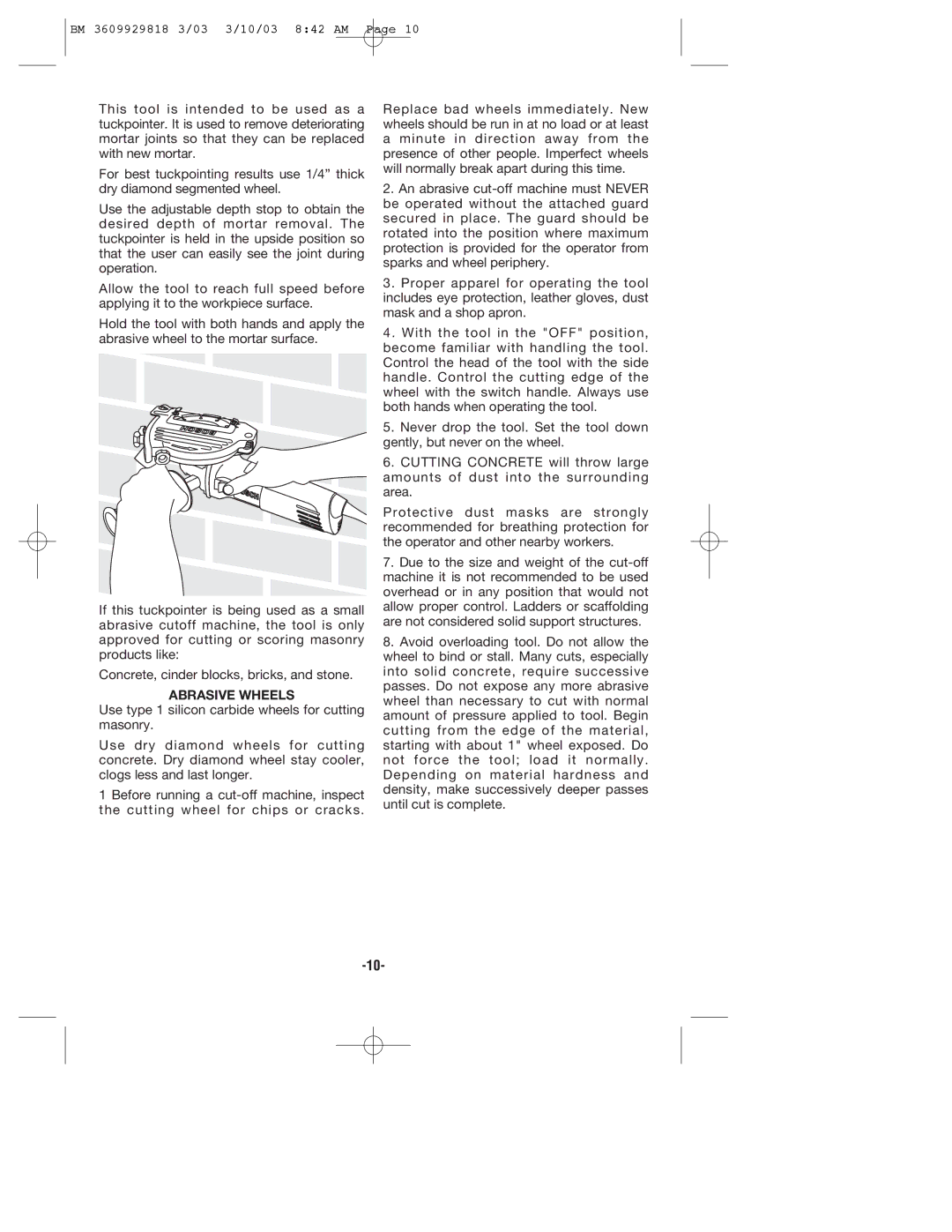

This tool is intended to be used as a tuckpointer. It is used to remove deteriorating mortar joints so that they can be replaced with new mortar.

For best tuckpointing results use 1/4” thick dry diamond segmented wheel.

Use the adjustable depth stop to obtain the desired depth of mortar removal. The tuckpointer is held in the upside position so that the user can easily see the joint during operation.

Allow the tool to reach full speed before applying it to the workpiece surface.

Hold the tool with both hands and apply the abrasive wheel to the mortar surface.

If this tuckpointer is being used as a small abrasive cutoff machine, the tool is only approved for cutting or scoring masonry products like:

Concrete, cinder blocks, bricks, and stone.

ABRASIVE WHEELS

Use type 1 silicon carbide wheels for cutting masonry.

Use dry diamond wheels for cutting concrete. Dry diamond wheel stay cooler, clogs less and last longer.

1 Before running a

Replace bad wheels immediately. New wheels should be run in at no load or at least a minute in direction away from the presence of other people. Imperfect wheels will normally break apart during this time.

2.An abrasive

3.Proper apparel for operating the tool includes eye protection, leather gloves, dust mask and a shop apron.

4. With the tool in the "OFF" position, become familiar with handling the tool. Control the head of the tool with the side handle. Control the cutting edge of the wheel with the switch handle. Always use both hands when operating the tool.

5.Never drop the tool. Set the tool down gently, but never on the wheel.

6.CUTTING CONCRETE will throw large amounts of dust into the surrounding area.

Protective dust masks are strongly recommended for breathing protection for the operator and other nearby workers.

7.Due to the size and weight of the

8.Avoid overloading tool. Do not allow the wheel to bind or stall. Many cuts, especially into solid concrete, require successive passes. Do not expose any more abrasive wheel than necessary to cut with normal amount of pressure applied to tool. Begin cutting from the edge of the material, starting with about 1" wheel exposed. Do not force the tool; load it normally. Depending on material hardness and density, make successively deeper passes until cut is complete.