Diamond Abrasive Blades

Diamond Blades

The pro’s clear cut choice

From the highest quality diamonds to superior Swiss manufacturing, each BOSCH diamond blade combines legendary engineering and extensive

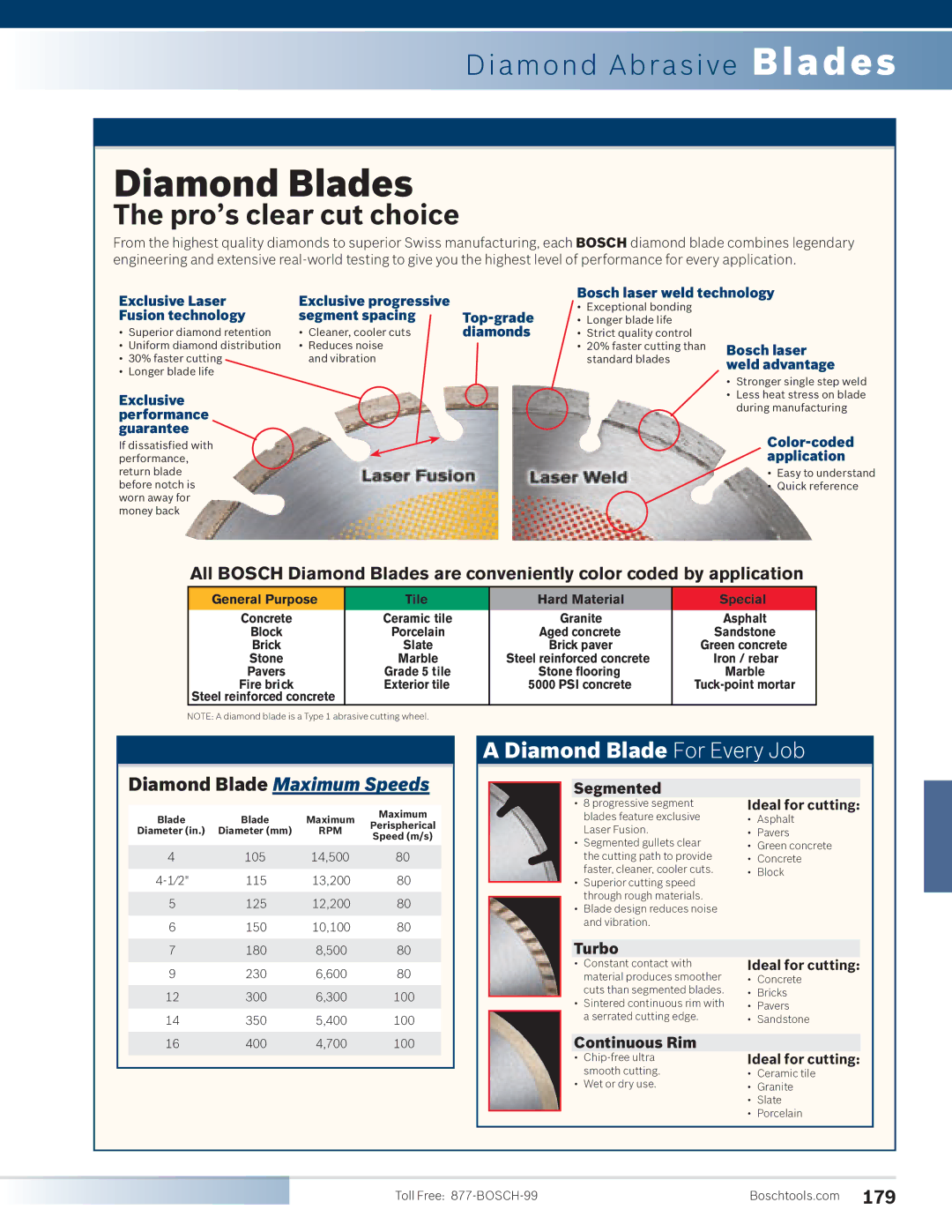

Exclusive Laser | Exclusive progressive |

Bosch laser weld technology

Fusion technology | segment spacing | |

• Superior diamond retention | • Cleaner, cooler cuts | diamonds |

• Uniform diamond distribution | • Reduces noise |

|

• 30% faster cutting | and vibration |

|

• Longer blade life |

|

|

Exclusive |

|

|

performance |

|

|

guarantee |

|

|

If dissatisfied with |

|

|

performance, |

|

|

return blade |

|

|

before notch is |

|

|

worn away for |

|

|

money back |

|

|

• Exceptional bonding • Longer blade life

• Strict quality control

• 20% faster cutting than standard blades

Bosch laser weld advantage

• Stronger single step weld • Less heat stress on blade during manufacturing

• Easy to understand • Quick reference

All BOSCH Diamond Blades are conveniently color coded by application

General Purpose | Tile | Hard Material | Special |

Concrete | Ceramic tile | Granite | Asphalt |

Block | Porcelain | Aged concrete | Sandstone |

Brick | Slate | Brick paver | Green concrete |

Stone | Marble | Steel reinforced concrete | Iron / rebar |

Pavers | Grade 5 tile | Stone flooring | Marble |

Fire brick | Exterior tile | 5000 PSI concrete | |

Steel reinforced concrete |

|

|

|

NOTE: A diamond blade is a Type 1 abrasive cutting wheel.

A Diamond Blade For Every Job

Diamond Blade Maximum Speeds

Blade | Blade | Maximum | Maximum | |

Perispherical | ||||

Diameter (in.) | Diameter (mm) | RPM | ||

Speed (m/s) | ||||

|

|

| ||

4 | 105 | 14,500 | 80 | |

115 | 13,200 | 80 | ||

5 | 125 | 12,200 | 80 | |

6 | 150 | 10,100 | 80 | |

7 | 180 | 8,500 | 80 | |

9 | 230 | 6,600 | 80 | |

12 | 300 | 6,300 | 100 | |

14 | 350 | 5,400 | 100 | |

16 | 400 | 4,700 | 100 |

Segmented

• 8 progressive segment blades feature exclusive Laser Fusion.

• Segmented gullets clear the cutting path to provide faster, cleaner, cooler cuts.

• Superior cutting speed through rough materials.

• Blade design reduces noise and vibration.

Turbo

• Constant contact with material produces smoother cuts than segmented blades.

• Sintered continuous rim with a serrated cutting edge.

Continuous Rim

•

• Wet or dry use.

Ideal for cutting:

• Asphalt • Pavers

• Green concrete • Concrete

• Block

Ideal for cutting:

• Concrete • Bricks • Pavers

• Sandstone

Ideal for cutting:

• Ceramic tile • Granite

• Slate

• Porcelain

Toll Free: | Boschtools.com 179 |