1853-5, 1853-6 specifications

Bosch Power Tools has long been a leader in the power tools industry, and the Bosch 1853-6 and 1853-5 models are exemplary representations of their commitment to quality, performance, and innovation. These tools are designed to meet the demanding needs of professional contractors and DIY enthusiasts alike.The Bosch 1853-6 is a 7-inch angle grinder that features a robust 15-amp motor, delivering a powerful performance for grinding, cutting, and polishing applications. Its advanced cooling system ensures that the tool remains efficient even under heavy load, preventing overheating and prolonging its lifespan. The grinder’s lightweight design enhances maneuverability, making it easier to use for extended periods without fatigue.

One of the standout features of the 1853-6 is the innovative Constant Electronic technology, which helps maintain speed under load. This means that even when the tool is under pressure, it will continue to operate at optimal speeds, ensuring consistent results. Additionally, the integrated vibration-dampening handle reduces strain on the user, allowing for increased comfort during prolonged use.

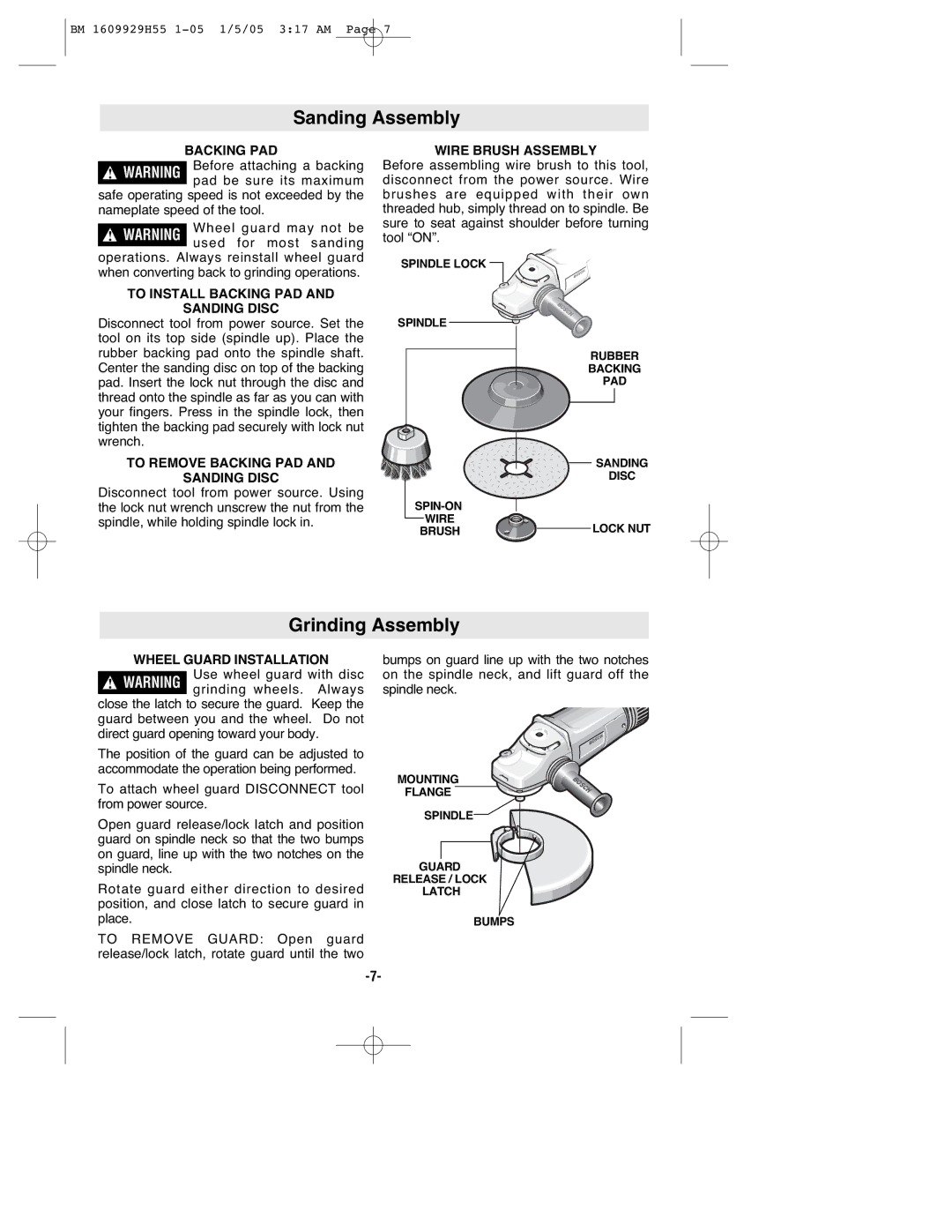

On the other hand, the Bosch 1853-5 model also boasts a similarly powerful 15-amp motor and incorporates some unique features tailored towards specific applications. This model is designed for a variety of cutting tasks, with a focus on precision and control. The 1853-5 is equipped with a spindle lock for easy disc changes and includes a guard that can be easily adjusted without the need for additional tools.

Both models highlight Bosch's emphasis on user safety. They are equipped with restart protection, which prevents accidental start-ups after a power interruption. Furthermore, the ergonomic design of the handles on both models ensures that users can achieve a firm grip, enhancing control during operation.

In terms of build quality, both models are constructed from durable materials designed to withstand tough job site conditions. They are engineered for longevity, making them reliable investments for any toolbox.

In summary, the Bosch 1853-6 and 1853-5 angle grinders represent the brand’s commitment to high-performance tools. With advanced technologies such as Constant Electronic, a focus on user safety, and sturdy construction, these angle grinders are versatile options that can handle a wide range of applications, ensuring they remain a favored choice among professionals and hobbyists alike.