275T6, 285T6, 395T6 specifications

Bosch Power Tools has long been a trusted name for professionals and DIY enthusiasts alike, and the models 275T6, 285T6, and 395T6 demonstrate the brand's commitment to innovation, durability, and high performance. Each of these tools is meticulously designed to cater to various applications while delivering efficiency and reliability.The Bosch 275T6 is a versatile tool that embodies power and precision. This corded electric tool features a robust motor that delivers exceptional torque and speed, making it ideal for heavy-duty tasks. One of its standout features is the variable speed control, allowing users to customize operation according to the material being worked on. Additionally, its ergonomic design ensures comfort during prolonged use, minimizing user fatigue. The 275T6 also incorporates advanced safety features, including a lock-on switch that prevents accidental activation and a protective housing that extends the tool's lifespan.

Next in line is the Bosch 285T6, which takes versatility a step further. This model is equipped with an innovative multi-functional design, allowing it to perform a variety of tasks, from drilling to sanding. Noteworthy is its quick-change chuck system, which enables users to switch between accessories with ease and efficiency. The 285T6 also features an integrated LED light that illuminates work areas, making it particularly useful in low-light conditions. Its lightweight construction does not compromise on durability, ensuring it can withstand rigorous use without hassle.

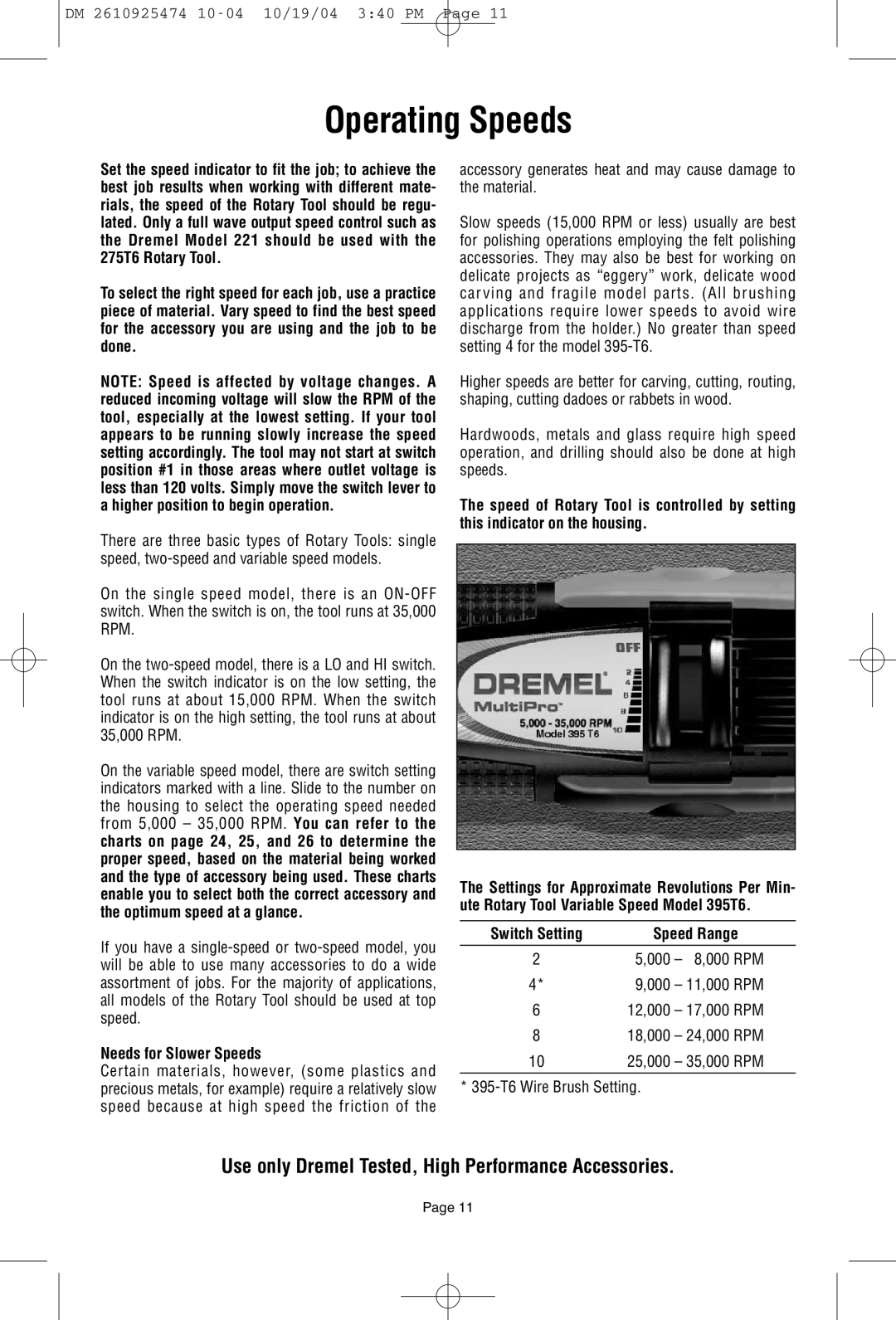

Finally, the Bosch 395T6 is designed for those who demand the highest performance under extreme conditions. This model boasts a heavy-duty motor that is optimized for high torque applications, making it perfect for demanding jobs in both wood and metal. The 395T6 incorporates tooth-tipped technology, enhancing cutting efficiency and prolonging blade life. In terms of user experience, the tool incorporates anti-vibration technology, which significantly reduces vibrations during operation, promoting stability and precision.

In summary, Bosch Power Tools' 275T6, 285T6, and 395T6 models are excellent choices for anyone in need of reliable and powerful tools. They come equipped with features that enhance user comfort, safety, and versatility. The combination of premium materials and innovative technology ensures these tools stand out in any toolbox, offering a robust solution for a wide range of applications. With Bosch, users can be assured of quality that translates into outstanding performance.