T55 TOOL SPECIFICATIONS

All screws and nuts are metric.

MODEL | LENGTH | HEIGHT | WIDTH | WEIGHT |

|

|

|

|

|

T55S4 | 14.50” (368mm) | 11.19” (284mm) | 3.62” (92mm) | 6.10lb.(2.77kg.) |

T55S5 | 14.50” (368mm) | 11.19” (284mm) | 3.62” (92mm) | 5.9lb.(2.68kg.) |

FASTENER SPECIFICATIONS:

MODEL | STAPLE SERIES | CROWN WIDTH | WIRE SIZE | MAXIMUM LEG LENGTH |

|

|

|

|

|

T55S4 | 1/2” (12.7mm) | .062” (1.58mm) | ||

|

|

|

|

|

T55S5 | 7/16” (11.1mm) | .054” (1.37mm) |

TOOL AIR FITTING:

This tool uses a

OPERATING PRESSURE:

The operating pressure of the T55 tool is 70 to 100 p.s.i. (4.9 to 7.1 kg/cm2). Select the operating pressure within

this range for best fastener performance. DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

AIR CONSUMPTION:

Model T55 requires 2.8 cubic feet per minute (.08 cubic meters) of free air to operate at the rate of 60 fasteners per minute, at 80 p.s.i. (5.6kg/cm2). Take the actual rate at which the tool will be run to determine the amount of air required. For instance, if your fastener usage averages 30 fasteners per minute, you need 50% of the tool's c.f.m. of free air which is required for running at 60 fasteners per minute.

OPERATION

CONTACT TRIP

The common operating procedure on “Contact Trip” tools is for the operator to contact the work to actuate the trip mechanism while keeping the trigger pulled, thus driving a fastener each time the work is contacted. This will allow rapid fastener placement on many jobs, such as sheathing, decking and pallet assembly.

All pneumatic tools are subject to recoil when driving fasteners. The tool may bounce, releasing the trip, and if unintentionally allowed to recontact the work surface with the trigger still actuated (finger still holding trigger pulled) an unwanted second fastener will be driven.

SEQUENTIAL TRIP

The Sequential Trip requires the operator to hold the tool against the work before pulling the trigger. This makes accurate fastener placement easier, for instance on framing, toe nailing and crating applications.

The Sequential Trip allows exact fastener location without the possibility of driving a second fastener on recoil, as described under “Contact Trip”.

The Sequential Trip Tool has a positive safety advantage because it will not accidentally drive a fastener if the tool is contacted against the work – or anything else – while the operator is holding the trigger pulled.

TRIGGER OPERATED

The Trigger Operated model is cycled by actuation of the trigger only. This model does not have a Contact Arm and is intended for use only where a Contact Arm CANNOT be used to satisfy the requirements of the application. The Trigger Operated tool will cycle each time the trigger is actuated.

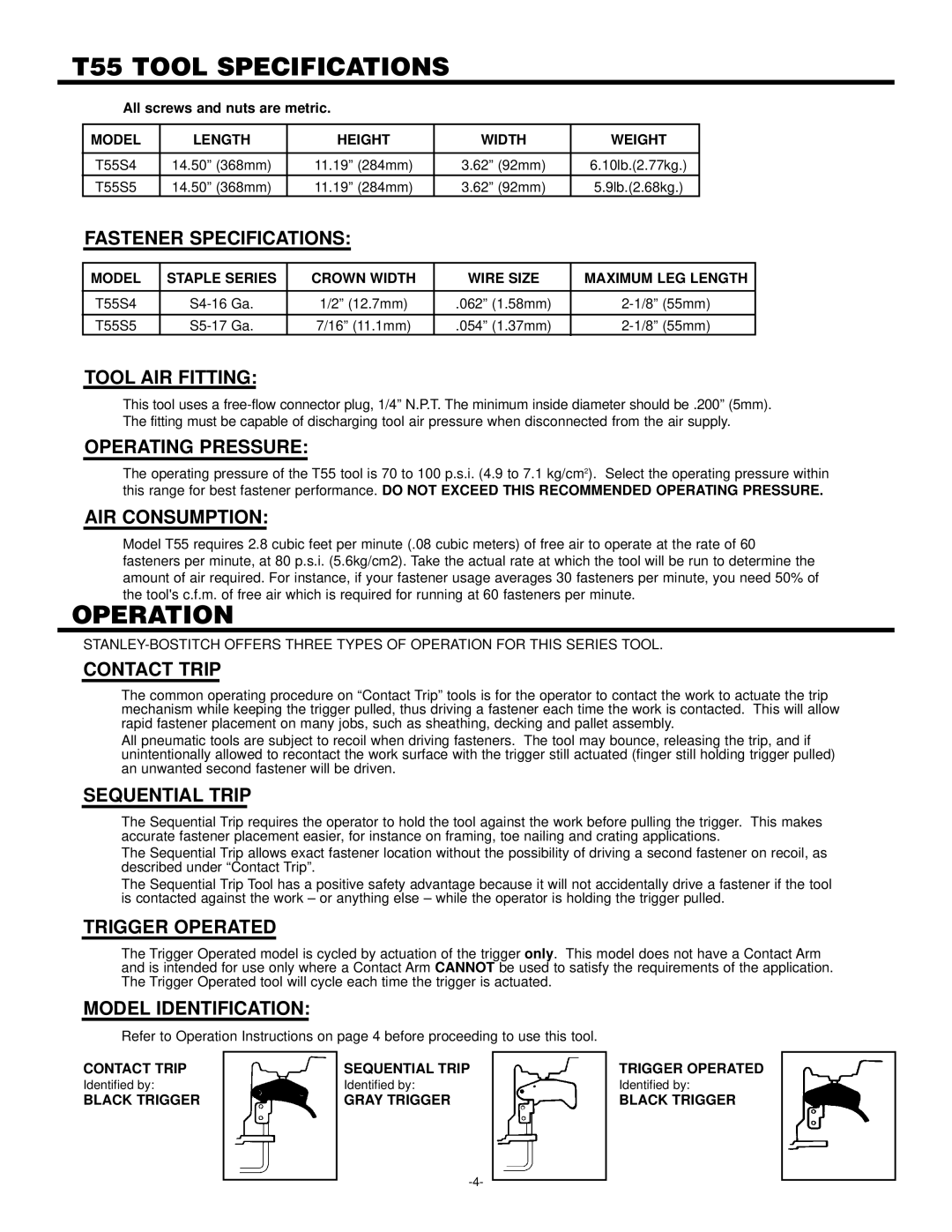

MODEL IDENTIFICATION:

Refer to Operation Instructions on page 4 before proceeding to use this tool.

CONTACT TRIP

Identified by:

BLACK TRIGGER

SEQUENTIAL TRIP

Identified by:

GRAY TRIGGER

TRIGGER OPERATED

Identified by:

BLACK TRIGGER