LOADING THE T55

EYE PROTECTION which conforms to ANSI specifications and provides protection against flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and others in the work area when loading, operating or servicing this tool. Eye protection is required to guard against flying fasteners and debris, which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to the requirements of the American National Standards Institute, ANSI

TO PREVENT ACCIDENTAL INJURIES:

•Never place a hand or any other part of the body in nail discharge area of tool while the air supply is connected.

•Never point the tool at anyone else.

•Never engage in horseplay.

•Never pull the trigger unless nose is directed at the work.

•Always handle the tool with care.

•Do not pull the trigger or depress the trip mechanism while loading the tool.

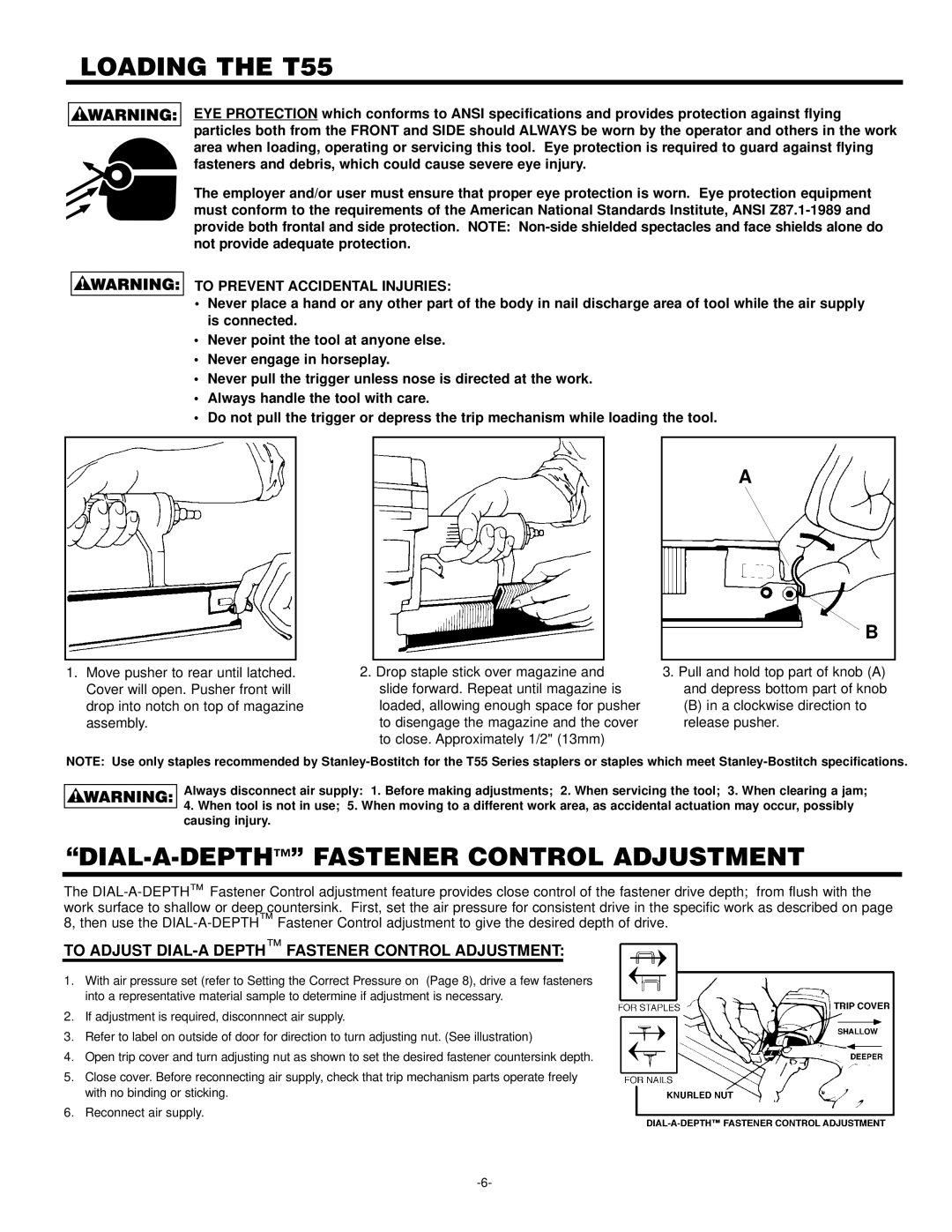

A

B

1.Move pusher to rear until latched. Cover will open. Pusher front will drop into notch on top of magazine assembly.

2.Drop staple stick over magazine and slide forward. Repeat until magazine is loaded, allowing enough space for pusher to disengage the magazine and the cover to close. Approximately 1/2" (13mm)

3.Pull and hold top part of knob (A) and depress bottom part of knob

(B)in a clockwise direction to release pusher.

NOTE: Use only staples recommended by

Always disconnect air supply: 1. Before making adjustments; 2. When servicing the tool; 3. When clearing a jam;

4.When tool is not in use; 5. When moving to a different work area, as accidental actuation may occur, possibly causing injury.

“DIAL-A-DEPTH™” FASTENER CONTROL ADJUSTMENT

The

TO ADJUST DIAL-A DEPTH™ FASTENER CONTROL ADJUSTMENT:

1.With air pressure set (refer to Setting the Correct Pressure on (Page 8), drive a few fasteners into a representative material sample to determine if adjustment is necessary.

2.If adjustment is required, disconnnect air supply.

3.Refer to label on outside of door for direction to turn adjusting nut. (See illustration)

4.Open trip cover and turn adjusting nut as shown to set the desired fastener countersink depth.

5.Close cover. Before reconnecting air supply, check that trip mechanism parts operate freely with no binding or sticking.

6.Reconnect air supply.