IGI-180C, IGI-180R specifications

Bradford-White Corporation is a well-known name in the water heating industry, offering a range of reliable and efficient products. Among its noteworthy offerings are the IGI-180R and IGI-180C indirect water heaters. These models exemplify the company's commitment to quality and innovation, featuring robust designs and cutting-edge technologies.The IGI-180R and IGI-180C units are designed to provide a consistent supply of hot water for residential and commercial applications. Both models have a storage capacity of 180 gallons, making them ideal for settings that require large volumes of hot water, such as restaurants, schools, and larger households. Their large tanks ensure minimal wait times and a reliable hot water supply, even during peak usage periods.

One of the key features of the IGI series is their indirect heating capability. Instead of relying on electric elements or gas burners, these heaters use a separate boiler or heating system to provide the necessary heat. This allows for more efficient operation, as the water is heated more evenly and effectively. The models integrate seamlessly with existing boiler systems, making them an excellent choice for those looking to upgrade or expand their hot water capabilities without extensive modifications.

Both the IGI-180R and IGI-180C incorporate advanced insulation technology, minimizing heat loss and improving energy efficiency. The high-density foam insulation encases the tank, keeping the water hot for longer periods and reducing energy costs associated with reheating. This insulation also contributes to a longer lifespan for the unit, as it reduces the wear and tear on the heating systems.

Another pivotal characteristic of these units is their durable construction. Bradford-White utilizes high-quality materials and rigorous manufacturing standards, ensuring that the IGI models withstand the test of time. The tanks are constructed from heavy-duty steel with a glass lining that protects against corrosion and sediment buildup, enhancing the longevity and performance of the water heater.

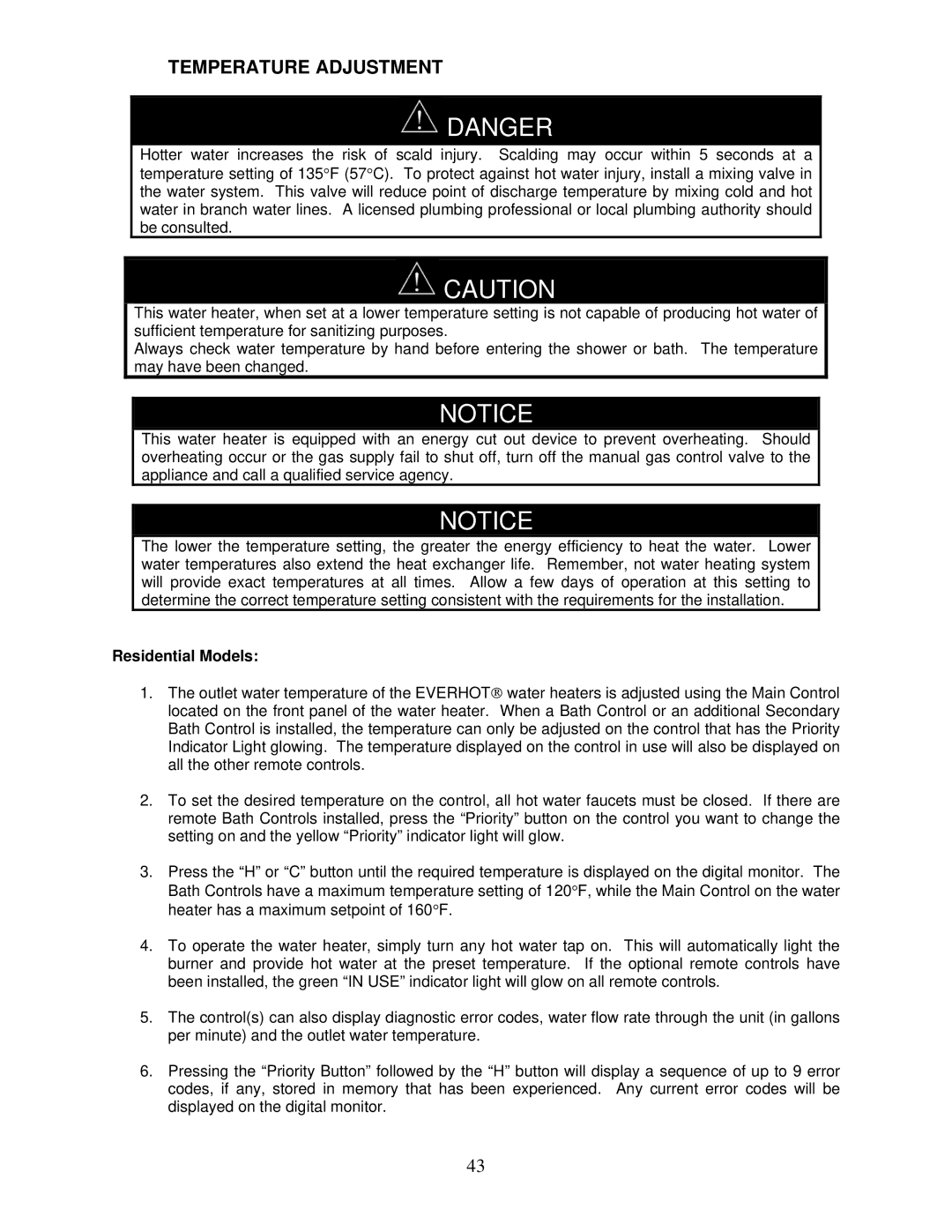

Lastly, both models come equipped with a range of safety features, including an integrated Pressure Relief Valve and a temperature control system. These elements safeguard against overheating and pressure issues, ensuring safe operation.

In conclusion, the IGI-180R and IGI-180C indirect water heaters by Bradford-White Corporation stand out for their efficient, reliable, and durable design. With advanced heating technology, excellent insulation, and robust safety features, they are a smart investment for any hot water demand scenario.