Section

7

Troubleshooting

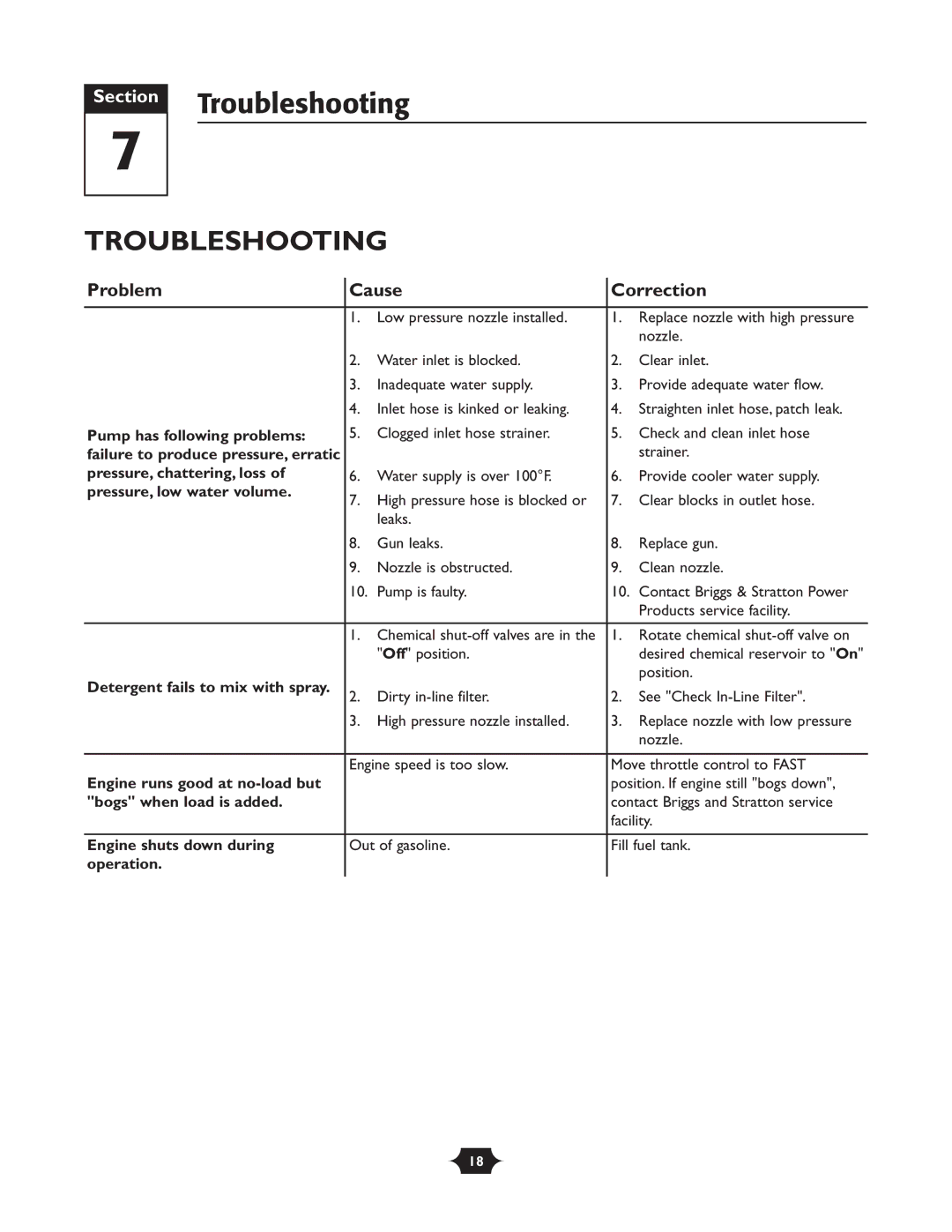

TROUBLESHOOTING

Problem | Cause | Correction | |||

|

|

|

|

| |

| 1. | Low pressure nozzle installed. | 1. | Replace nozzle with high pressure | |

|

|

|

| nozzle. | |

| 2. | Water inlet is blocked. | 2. | Clear inlet. | |

| 3. | Inadequate water supply. | 3. | Provide adequate water flow. | |

| 4. | Inlet hose is kinked or leaking. | 4. | Straighten inlet hose, patch leak. | |

Pump has following problems: | 5. | Clogged inlet hose strainer. | 5. | Check and clean inlet hose | |

failure to produce pressure, erratic |

|

|

| strainer. | |

pressure, chattering, loss of | 6. | Water supply is over 100°F. | 6. | Provide cooler water supply. | |

pressure, low water volume. | 7. | High pressure hose is blocked or | 7. | Clear blocks in outlet hose. | |

| |||||

|

| leaks. |

|

| |

| 8. | Gun leaks. | 8. | Replace gun. | |

| 9. | Nozzle is obstructed. | 9. | Clean nozzle. | |

| 10. | Pump is faulty. | 10. | Contact Briggs & Stratton Power | |

|

|

|

| Products service facility. | |

|

|

|

|

| |

| 1. | Chemical | 1. | Rotate chemical | |

|

| "Off" position. |

| desired chemical reservoir to "On" | |

Detergent fails to mix with spray. |

|

|

| position. | |

2. | Dirty | 2. | See "Check | ||

| |||||

| 3. | High pressure nozzle installed. | 3. | Replace nozzle with low pressure | |

|

|

|

| nozzle. | |

|

|

| |||

| Engine speed is too slow. | Move throttle control to FAST | |||

Engine runs good at |

|

| position. If engine still "bogs down", | ||

"bogs" when load is added. |

|

| contact Briggs and Stratton service | ||

|

|

| facility. | ||

|

|

| |||

Engine shuts down during | Out of gasoline. | Fill fuel tank. | |||

operation. |

|

|

|

| |

|

|

|

|

| |

18