Initial Start-up (No Load)

Before operating the home generator or placing it into service, inspect the entire installation carefully.

Then begin testing the system without any electrical loads connected, as follows:

1.Set generator’s main circuit breaker to its ON (closed) position.

2.Install 15 Amp fuse in control panel.

3.Set generator’s system switch to AUTO.

4.Push MANUAL

NOTE: When the home generator is started for the very first time, it will require that air in the gaseous fuel lines be purged. This may take a few minutes.

5.DO NOT crank engine for more than 10 seconds, then pause for 10 seconds to reduce heat in the starter.

6.Repeat process until engine starts.

7.Listen for unusual noises, vibration or other indications of abnormal operation. Check for oil leaks while engine runs.

8.Let engine warm up for about five minutes to allow internal temperatures to stabilize.

9.Connect an accurate AC voltmeter and a frequency meter to check generator output at load side of circuit breaker. Voltage should be 239‑262 Volts, frequency should be 62.0 - 62.5 Hz.

NOTE: If either parameter is outside these ranges, perform the Engine Adjustments described below.

10.Check generator output between one of the generator connection lugs and the neutral lug, then between the other generator connection lug and the neutral lug.

In both cases, voltage reading should be between 119‑131 Volts.

11.Push and hold MANUAL

IMPORTANT: DO NOT proceed until you are certain that generator AC voltage and frequency are correct and within the stated limits. To obtain the proper generator frequency, see Engine Adjustments.

14

Engine Adjustment

Each home generator unit leaves the factory set for either NG or LP gas operation. There are regional variances in the composition of natural gas. If the generator output voltage or frequency measured during Initial

To adjust the engine for this difference, proceed as follows.

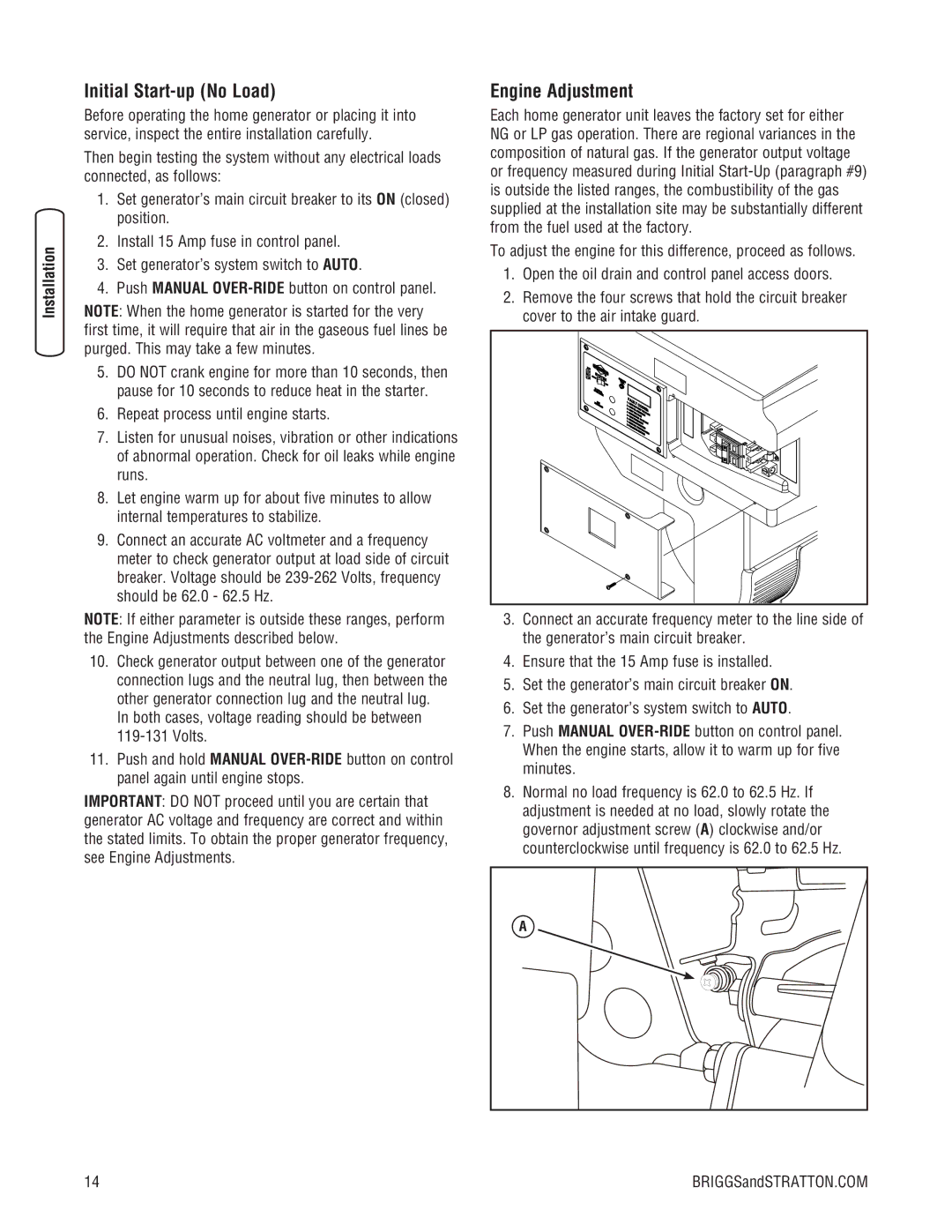

1.Open the oil drain and control panel access doors.

2.Remove the four screws that hold the circuit breaker cover to the air intake guard.

3.Connect an accurate frequency meter to the line side of the generator’s main circuit breaker.

4.Ensure that the 15 Amp fuse is installed.

5.Set the generator’s main circuit breaker ON.

6.Set the generator’s system switch to AUTO.

7.Push MANUAL

8.Normal no load frequency is 62.0 to 62.5 Hz. If adjustment is needed at no load, slowly rotate the governor adjustment screw (A) clockwise and/or counterclockwise until frequency is 62.0 to 62.5 Hz.

A |

BRIGGSandSTRATTON.COM |