380700, 381700, 351700, 380700, 381700 specifications

Briggs & Stratton has been a leading name in small engine manufacturing, known for their durability and performance across various applications. Among their lineup, models like the 381700, 380700, and 351700 stand out for their innovative features and reliable technology. These engines are widely utilized in outdoor power equipment, ranging from lawn mowers to generators, making them a versatile choice for both homeowners and professionals.The Briggs & Stratton 381700 engine is designed with an overhead valve (OHV) configuration, which enhances fuel efficiency and increases power output. This model features a single-cylinder design that offers a compact footprint while delivering robust performance. The engine's Easy Start technology minimizes the pull force necessary to start the engine, making operation smoother and more user-friendly. Additionally, the 381700 incorporates a splash lubrication system that ensures reliable engine operation and protects moving parts from wear, thereby extending engine life.

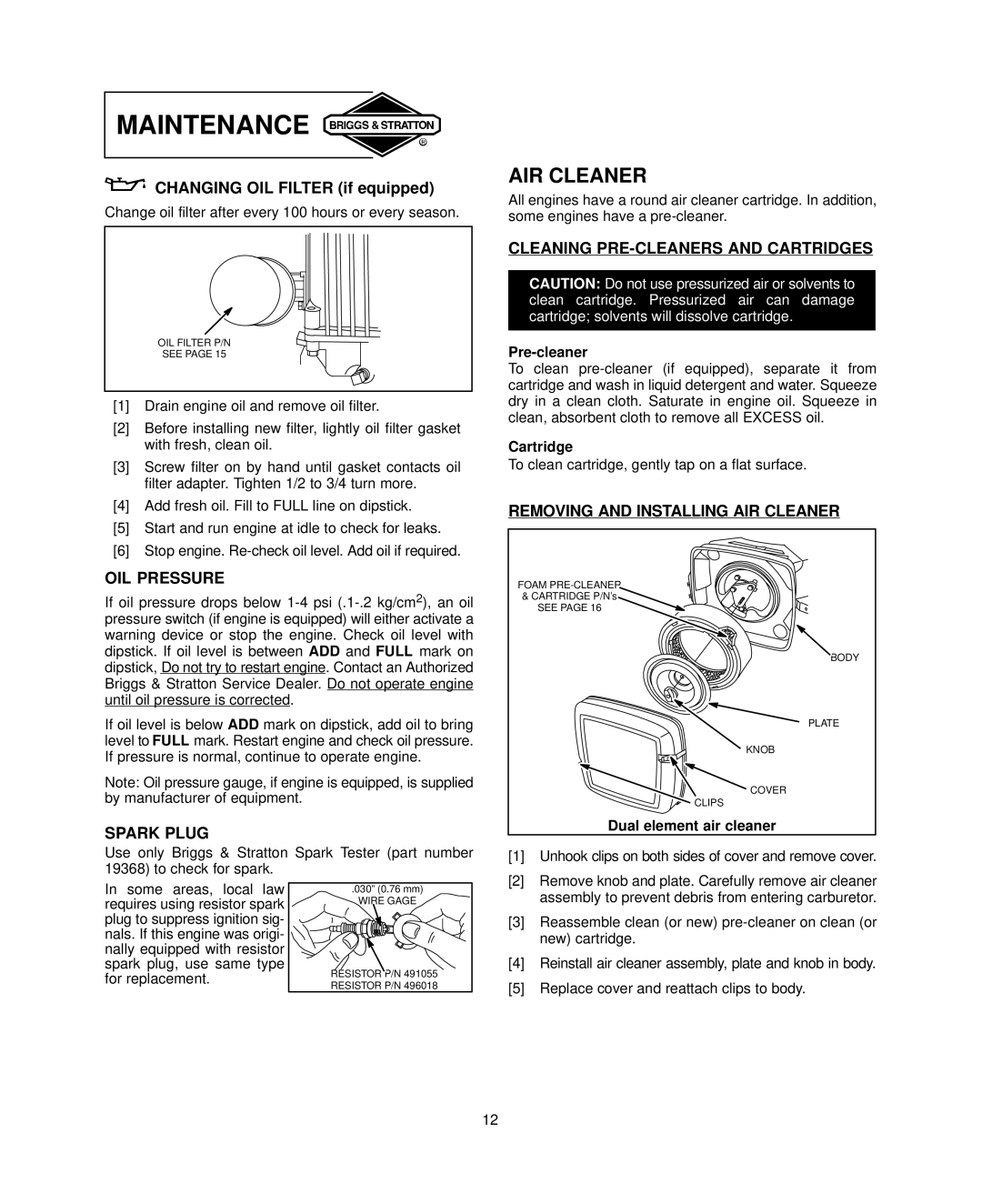

The 380700 engine boasts similar features, with the addition of digital ignition technology that optimizes spark timing, leading to improved fuel combustion and reduced emissions. The ability to adapt to varying load conditions enhances performance in diverse applications. Another standout characteristic is its large air filter, which increases airflow and helps maintain engine cleanliness, further boosting efficiency.

The 351700 model focuses on compact design and portability, making it an excellent choice for equipment requiring a smaller engine footprint. It employs a durable construction, emphasizing heavy-duty components that can withstand rigorous usage. The engine's maintenance-friendly design, with easily accessible components, facilitates routine checks and repairs, minimizing downtime for users.

All three models are built to last, showcasing Briggs & Stratton's commitment to high-quality manufacturing and customer satisfaction. Their engines are designed for easy maintenance, featuring spin-on oil filters and large oil capacities, ensuring extended intervals between oil changes. The durability of the materials used also contributes to the longevity of these engines, making them a wise investment for any equipment operator.

In conclusion, the Briggs & Stratton 381700, 380700, and 351700 engines are exemplary models that demonstrate the brand's dedication to performance, reliability, and user experience. Whether you need an engine for residential or commercial use, these models provide the power, efficiency, and ease of maintenance that customers have come to expect from a trusted name in small engines. With advanced technologies and robust design, they are well-equipped to handle various demanding tasks in outdoor equipment applications.