17MAINTENANCE

Use only a qualified mechanic for any adjustments, disassembly or any kind of repair .

WARNING: TO AVOID PERSONAL INJURY, ALWAYS TURN MACHINE OFF, MAKE SURE ALL MOVING PARTS COME TO A COM- PLETE STOP.

DISCONNECT SPARK PLUG WIRE BEFORE SERVICING UNIT.

RECONNECT SPARK PLUG WIRE, AND ALL GUARDS BEFORE STARTING ENGINE.

Note: Blade, blade brake puck, transaxle brake, and drive belts are normal wear items. These should be inspected on a regular basis and replaced if worn.

MAINTENANCE HISTORY

Date of Service

Service Performed

ADJUST ALL BELT TENSIONS AFTER FIRST 5 HRS. OF USE TO PROLONG THE LIFE OF BELTS.

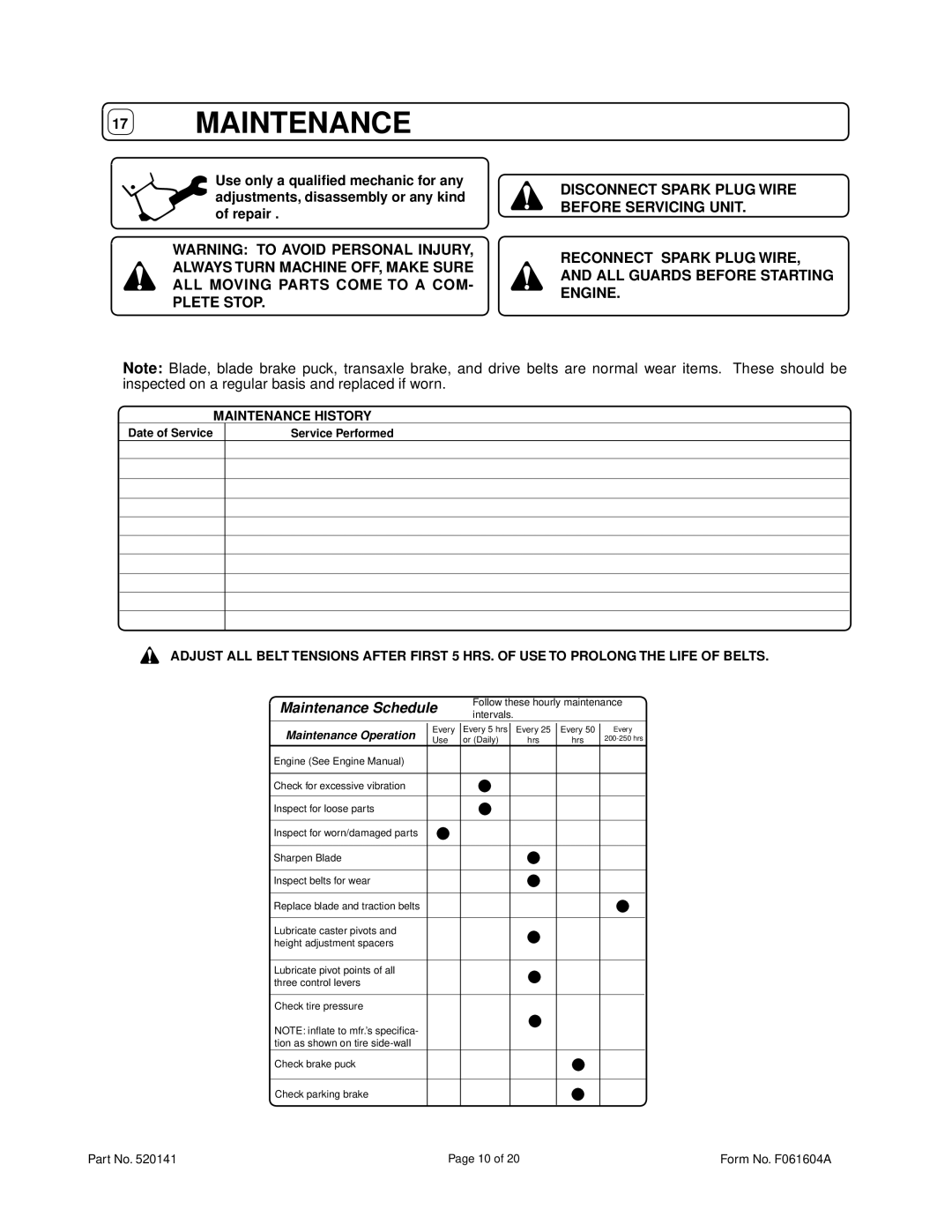

Maintenance Schedule

Follow these hourly maintenance intervals.

Maintenance Operation | Every | Every 5 hrs | Every 25 | Every 50 Every | |

Use | or (Daily) | hrs | hrs | ||

|

| ||||

Engine (See Engine Manual)

Check for excessive vibration

Inspect for loose parts

Inspect for worn/damaged parts

Sharpen Blade

Inspect belts for wear

Replace blade and traction belts

Lubricate caster pivots and height adjustment spacers

Lubricate pivot points of all three control levers

Check tire pressure

NOTE: inflate to mfr.’s specifica- tion as shown on tire

Check brake puck

Check parking brake

Part No. 520141 | Page 10 of 20 | Form No. F061604A |