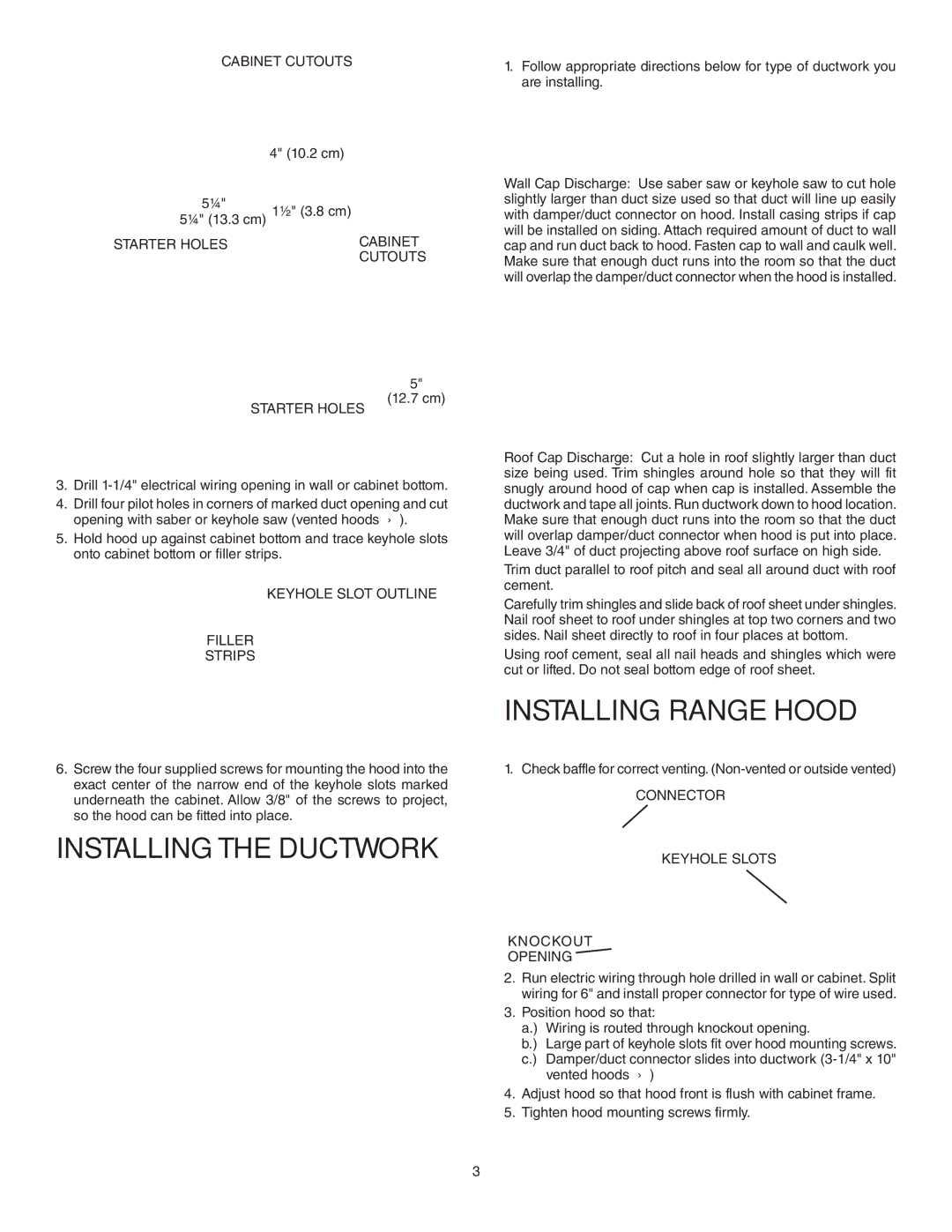

CABINET CUTOUTS

1. Follow appropriate directions below for type of ductwork you |

are installing. |

5¼"

5¼" (13.3 cm)

RECTANGULAR

VENTING

4" (10.2 cm)

1½" (3.8 cm)

Wall Cap Discharge: Use saber saw or keyhole saw to cut hole slightly larger than duct size used so that duct will line up easily with damper/duct connector on hood. Install casing strips if cap will be installed on siding. Attach required amount of duct to wall

STARTER HOLES | CABINET |

| CUTOUTS |

cap and run duct back to hood. Fasten cap to wall and caulk well. Make sure that enough duct runs into the room so that the duct will overlap the damper/duct connector when the hood is installed.

7" ROUND

VENTING

STARTER HOLES

5"

(12.7 cm)

WARNING: WHEN CUTTING OR DRILLING INTO WALL OR CABINET, BE CAREFUL NOT TO CUT EXISTING ELECTRI- CAL WIRING.

3.Drill

4.Drill four pilot holes in corners of marked duct opening and cut opening with saber or keyhole saw (vented hoods only).

5.Hold hood up against cabinet bottom and trace keyhole slots onto cabinet bottom or filler strips.

KEYHOLE SLOT OUTLINE

FILLER

STRIPS

6.Screw the four supplied screws for mounting the hood into the exact center of the narrow end of the keyhole slots marked underneath the cabinet. Allow 3/8" of the screws to project, so the hood can be fitted into place.

INSTALLING THE DUCTWORK

THESE INSTRUCTIONS ARE FOR VENTED HOODS ONLY.

START AT THE EXTERIOR AND RUN DUCTWORK BACK TO THE RANGE HOOD.

FOR BEST PERFORMANCE OF YOUR RANGE HOOD, USE THE SHORTEST POSSIBLE DUCT RUN AND A MINIMUM NUMBER OF ELBOWS.

NEVER VENT A RANGE HOOD INTO AN ATTIC SPACE BECAUSE A BUILDUP OF GREASE WILL BECOME A FIRE HAZARD.

USE ONLY METAL DUCTWORK (DO NOT USE PLASTIC DUCT). ASSEMBLE SECURELY SO THAT IN CASE OF A GREASE FIRE ON THE RANGE, THE FIRE WILL BE CON- TAINED INSIDE METAL DUCTWORK.

IT IS A GOOD PRACTICETOTAPE ALL DUCT CONNECTIONS, MAKING THEM BOTH SECURE AND AIR TIGHT.

3

Roof Cap Discharge: Cut a hole in roof slightly larger than duct size being used. Trim shingles around hole so that they will fit snugly around hood of cap when cap is installed. Assemble the ductwork and tape all joints. Run ductwork down to hood location. Make sure that enough duct runs into the room so that the duct will overlap damper/duct connector when hood is put into place. Leave 3/4" of duct projecting above roof surface on high side.

Trim duct parallel to roof pitch and seal all around duct with roof cement.

Carefully trim shingles and slide back of roof sheet under shingles. Nail roof sheet to roof under shingles at top two corners and two sides. Nail sheet directly to roof in four places at bottom.

Using roof cement, seal all nail heads and shingles which were cut or lifted. Do not seal bottom edge of roof sheet.

INSTALLING RANGE HOOD

WARNING: TURN OFF THE PROPER CIRCUIT AT THE SER- VICE ENTRANCE BEFORE WIRING THIS RANGE HOOD.

1.Check baffle for correct venting.

CONNECTOR

KEYHOLE SLOTS

KNOCKOUT

OPENING

2.Run electric wiring through hole drilled in wall or cabinet. Split wiring for 6" and install proper connector for type of wire used.

3.Position hood so that:

a.) Wiring is routed through knockout opening.

b.) Large part of keyhole slots fit over hood mounting screws. c.) Damper/duct connector slides into ductwork

vented hoods only)

4.Adjust hood so that hood front is flush with cabinet frame.

5.Tighten hood mounting screws firmly.