MODELS

L100L • L150L • L200L • L250L • L300L

Page 3

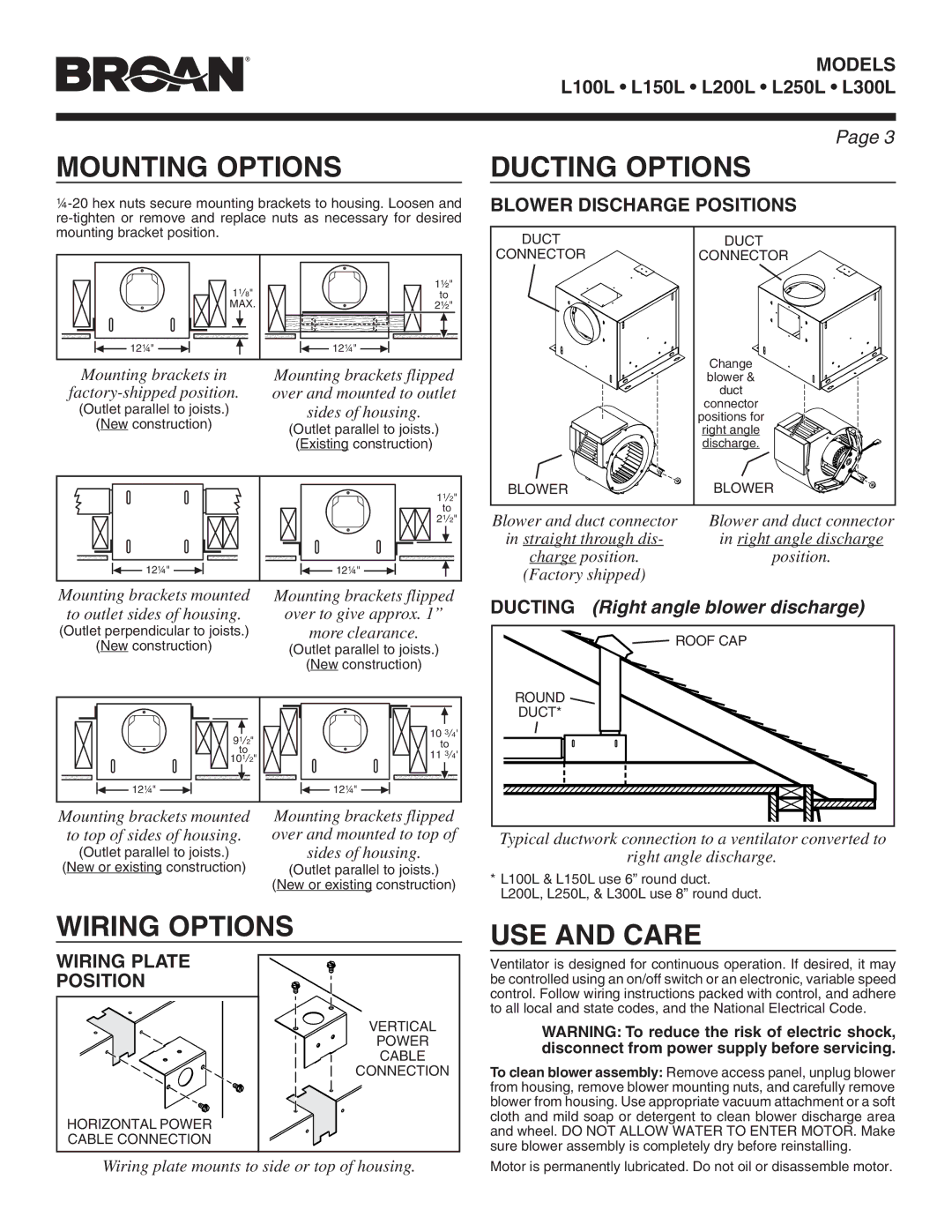

MOUNTING OPTIONS |

| DUCTING OPTIONS |

11/ 8" | 1½" |

to | |

MAX. | 2½" |

12¼" | 12¼" |

Mounting brackets in | Mounting brackets flipped |

over and mounted to outlet | |

(Outlet parallel to joists.) | sides of housing. |

(New construction) | (Outlet parallel to joists.) |

| (Existing construction) |

| 11/ 2" |

| to |

| 21/ 2" |

12¼" | 12¼" |

Mounting brackets mounted | Mounting brackets flipped |

to outlet sides of housing. | over to give approx. 1” |

(Outlet perpendicular to joists.) | more clearance. |

(New construction) | (Outlet parallel to joists.) |

| (New construction) |

91/ 2" | 10 3/ 4" | |

to | ||

to | ||

11 3/ 4" | ||

101/ 2" | ||

12¼" | 12¼" |

Mounting brackets mounted | Mounting brackets flipped |

to top of sides of housing. | over and mounted to top of |

(Outlet parallel to joists.) | sides of housing. |

(New or existing construction) | (Outlet parallel to joists.) |

| (New or existing construction) |

BLOWER DISCHARGE POSITIONS

DUCT | DUCT |

CONNECTOR | CONNECTOR |

| Change |

| blower & |

| duct |

| connector |

| positions for |

| right angle |

| discharge. |

BLOWER | BLOWER |

Blower and duct connector | Blower and duct connector |

in straight through dis- | in right angle discharge |

charge position. | position. |

(Factory shipped) |

|

DUCTING (Right angle blower discharge)

ROOF CAP |

ROUND |

DUCT* |

Typical ductwork connection to a ventilator converted to right angle discharge.

*L100L & L150L use 6” round duct.

L200L, L250L, & L300L use 8” round duct.

WIRING OPTIONS

WIRING PLATE |

POSITION |

VERTICAL |

POWER |

CABLE |

CONNECTION |

HORIZONTAL POWER |

CABLE CONNECTION |

Wiring plate mounts to side or top of housing.

USE AND CARE

Ventilator is designed for continuous operation. If desired, it may be controlled using an on/off switch or an electronic, variable speed control. Follow wiring instructions packed with control, and adhere to all local and state codes, and the National Electrical Code.

WARNING: To reduce the risk of electric shock, disconnect from power supply before servicing.

To clean blower assembly: Remove access panel, unplug blower from housing, remove blower mounting nuts, and carefully remove blower from housing. Use appropriate vacuum attachment or a soft cloth and mild soap or detergent to clean blower discharge area and wheel. DO NOT ALLOW WATER TO ENTER MOTOR. Make sure blower assembly is completely dry before reinstalling.

Motor is permanently lubricated. Do not oil or disassemble motor.