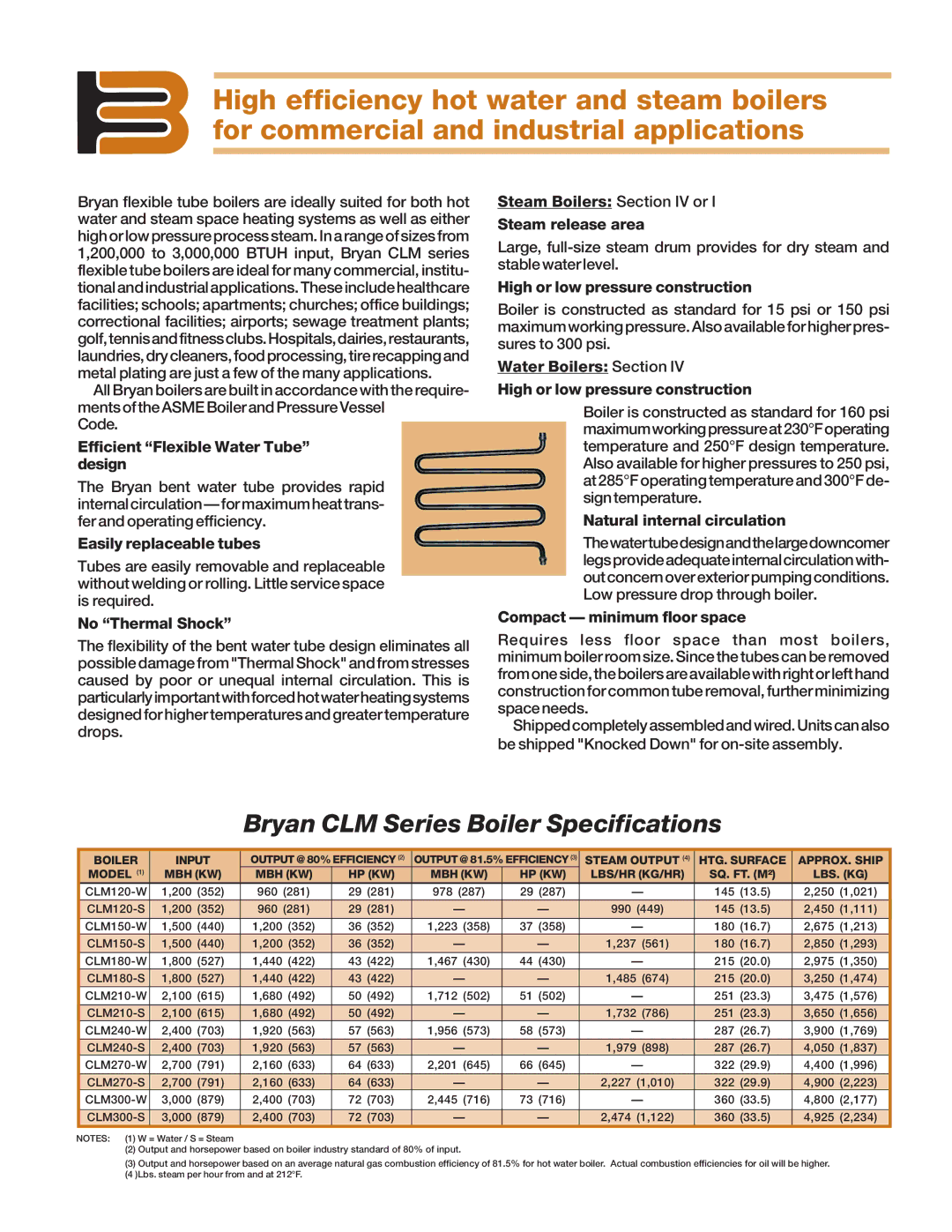

CLM Series specifications

The Bryan Boilers CLM Series represents a cutting-edge advancement in the realm of commercial water-tube boilers, designed to meet the rigorous demands of various industrial applications. Known for its reliability and efficiency, this series is particularly well-suited for those seeking a high-performance, compact boiler solution.One of the main features of the CLM Series is its modular design, which allows for easy transportation and installation. The compact structure provides flexibility in space-constrained environments while ensuring optimal performance. This modularity also enables quick scalability, accommodating the changing needs of a business without the hassle of extensive modifications.

Another standout characteristic of the CLM Series is its enhanced efficiency. The series employs a unique combustion process that maximizes fuel utilization. This efficiency translates into significant cost savings for users, as the reduced fuel consumption leads to lower operating expenses. Moreover, the CLM boilers are designed to operate effectively with a range of fuel types, including natural gas, propane, and biofuels, making them versatile for diverse operational contexts.

The CLM Series also employs advanced control technologies. The integrated microprocessor controls enhance operational precision, allowing for adaptive response to varying load conditions. These intelligent controls ensure optimal combustion efficiency, precise temperature management, and minimized emissions. This aligns with increasingly stringent environmental regulations, allowing businesses to operate sustainably without sacrificing performance.

In terms of safety and reliability, the CLM Series is equipped with multiple safety features, including flame monitoring systems and pressure controls. These safety mechanisms work in concert to provide peace of mind for operators while minimizing the risks associated with boiler operations.

Another notable characteristic of the CLM Series is its impressive lifespan. Built with high-quality materials and robust engineering, these boilers are designed to endure heavy-duty usage across various applications. This durability not only reduces the frequency of replacement but also enhances overall system reliability.

In summary, the Bryan Boilers CLM Series stands out in the market as an efficient, reliable, and versatile solution for commercial and industrial heating needs. With its modular design, advanced control technologies, fuel flexibility, and a strong emphasis on safety and durability, the CLM Series is positioned as a leading choice for businesses seeking sustainable and high-performance boiler solutions.