HE-CLM Series, HE-CLM300-W-FDG specifications

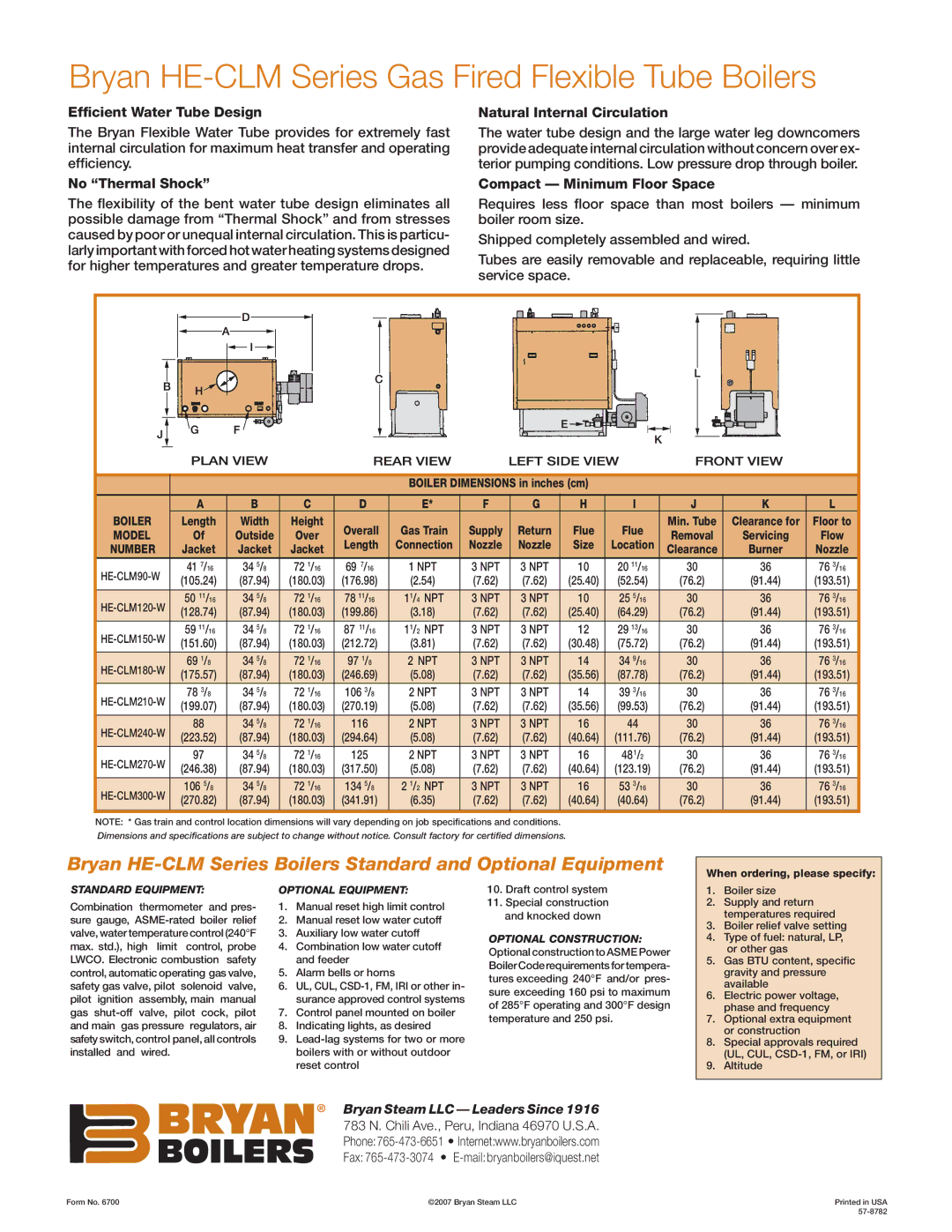

The Bryan Boilers HE-CLM300-W-FDG is a prominent example of modern heating technology, specifically designed for efficiency and reliability in various industrial applications. As part of the HE-CLM series, this boiler offers advanced features that cater to the evolving needs of energy generation and distribution in commercial and industrial businesses.One of the main features of the HE-CLM300-W-FDG is its compact design, which allows for flexible installation in space-constrained environments. Despite its small footprint, the system boasts a significant steam output of 300 horsepower, providing ample capacity for demanding operational needs.

The high-efficiency water tube design is a standout characteristic of the HE-CLM series, enabling rapid steam generation and exceptional heat transfer. This design ensures that the boiler operates at high thermal efficiency, reducing overall fuel consumption and minimizing operational costs. The integration of a sophisticated forced-draft burner technology further enhances the performance of the HE-CLM300 model by optimizing the air-to-fuel ratio, which leads to cleaner combustion and lower emissions.

Equipped with advanced control systems, the HE-CLM300-W-FDG provides precise temperature and pressure regulation, allowing operators to easily manage steam production and adapt to varying load demands. The user-friendly interface simplifies monitoring and adjustments, making it accessible for personnel at all skill levels.

Safety is a crucial consideration in boiler design, and the HE-CLM series incorporates multiple safety features including a low-water cutoff, pressure relief valves, and automatic restart capabilities. These features ensure reliable operation and protect personnel and equipment from potential hazards.

The HE-CLM300-W-FDG is constructed with durable materials to withstand the rigors of industrial use. The boiler’s robust build quality also contributes to longevity and reduced maintenance needs, making it a sound investment for operations looking to enhance productivity without sacrificing reliability.

In summary, the Bryan Boilers HE-CLM300-W-FDG model from the HE-CLM series exemplifies modern boiler technology with its efficient design, advanced features, and commitment to safety. Companies seeking a powerful and economical solution for steam generation will find this model to be an excellent choice. The combination of efficiency, user-friendly controls, and robust safety features makes the HE-CLM300 an ideal solution for a wide range of industrial heating needs.