MOUNTING

SCREWS

RELIEF

BOX

CONTROL

W![]()

![]()

Y |

R |

G |

BLOCKED VENT SAFEGUARD

FLUE COLLECTOR BOX

FILTER RETAINER

WASHABLE FILTER

| VENT PIPE |

| ENCLOSURE |

AUXILIARY |

|

LIMIT |

|

SWITCH |

|

(WHEN USED) |

|

MOUNTING | CONTROL |

SCREWS | BOARD |

| BLOCKED |

| VENT |

RELIEF | SAFEGUARD |

BOX |

|

| MANUAL |

| RESET LIMIT |

| SWITCHES |

A98528

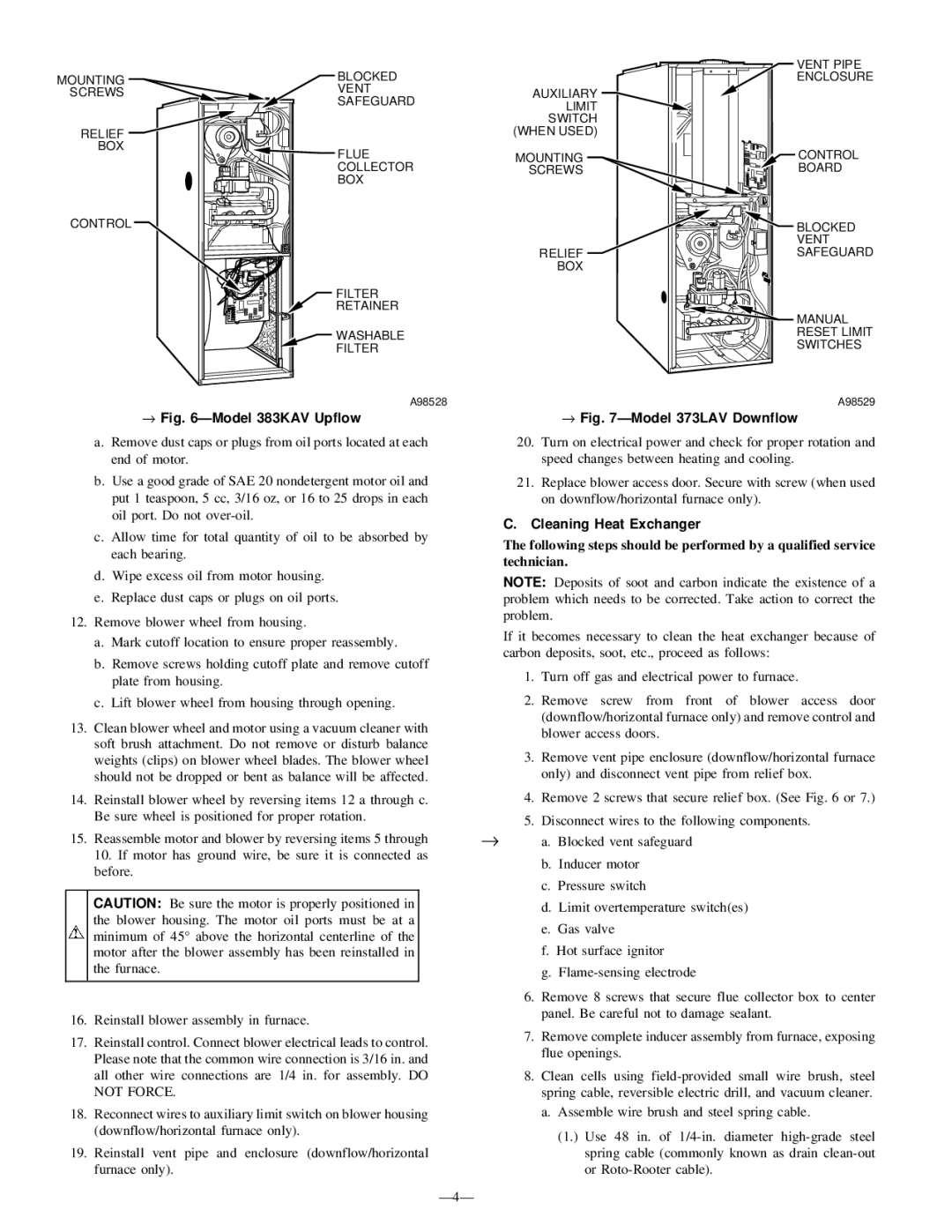

→Fig. 6ÐModel 383KAV Upflow

A98529 |

→Fig. 7ÐModel 373LAV Downflow

a.Remove dust caps or plugs from oil ports located at each end of motor.

b.Use a good grade of SAE 20 nondetergent motor oil and put 1 teaspoon, 5 cc, 3/16 oz, or 16 to 25 drops in each oil port. Do not

c.Allow time for total quantity of oil to be absorbed by each bearing.

d.Wipe excess oil from motor housing.

e.Replace dust caps or plugs on oil ports.

12.Remove blower wheel from housing.

a.Mark cutoff location to ensure proper reassembly.

b.Remove screws holding cutoff plate and remove cutoff plate from housing.

c.Lift blower wheel from housing through opening.

13.Clean blower wheel and motor using a vacuum cleaner with soft brush attachment. Do not remove or disturb balance weights (clips) on blower wheel blades. The blower wheel should not be dropped or bent as balance will be affected.

14.Reinstall blower wheel by reversing items 12 a through c. Be sure wheel is positioned for proper rotation.

15.Reassemble motor and blower by reversing items 5 through 10. If motor has ground wire, be sure it is connected as before.

CAUTION: Be sure the motor is properly positioned in the blower housing. The motor oil ports must be at a

minimum of 45° above the horizontal centerline of the motor after the blower assembly has been reinstalled in the furnace.

16.Reinstall blower assembly in furnace.

17.Reinstall control. Connect blower electrical leads to control. Please note that the common wire connection is 3/16 in. and all other wire connections are 1/4 in. for assembly. DO NOT FORCE.

18.Reconnect wires to auxiliary limit switch on blower housing (downflow/horizontal furnace only).

19.Reinstall vent pipe and enclosure (downflow/horizontal furnace only).

20.Turn on electrical power and check for proper rotation and speed changes between heating and cooling.

21.Replace blower access door. Secure with screw (when used on downflow/horizontal furnace only).

C.Cleaning Heat Exchanger

The following steps should be performed by a qualified service technician.

NOTE: Deposits of soot and carbon indicate the existence of a problem which needs to be corrected. Take action to correct the problem.

If it becomes necessary to clean the heat exchanger because of carbon deposits, soot, etc., proceed as follows:

1.Turn off gas and electrical power to furnace.

2.Remove screw from front of blower access door (downflow/horizontal furnace only) and remove control and blower access doors.

3.Remove vent pipe enclosure (downflow/horizontal furnace only) and disconnect vent pipe from relief box.

4.Remove 2 screws that secure relief box. (See Fig. 6 or 7.)

5.Disconnect wires to the following components.

→a. Blocked vent safeguard

b.Inducer motor

c.Pressure switch

d.Limit overtemperature switch(es)

e.Gas valve

f.Hot surface ignitor

g.

6.Remove 8 screws that secure flue collector box to center panel. Be careful not to damage sealant.

7.Remove complete inducer assembly from furnace, exposing flue openings.

8.Clean cells using

a.Assemble wire brush and steel spring cable.

(1.) Use 48 in. of