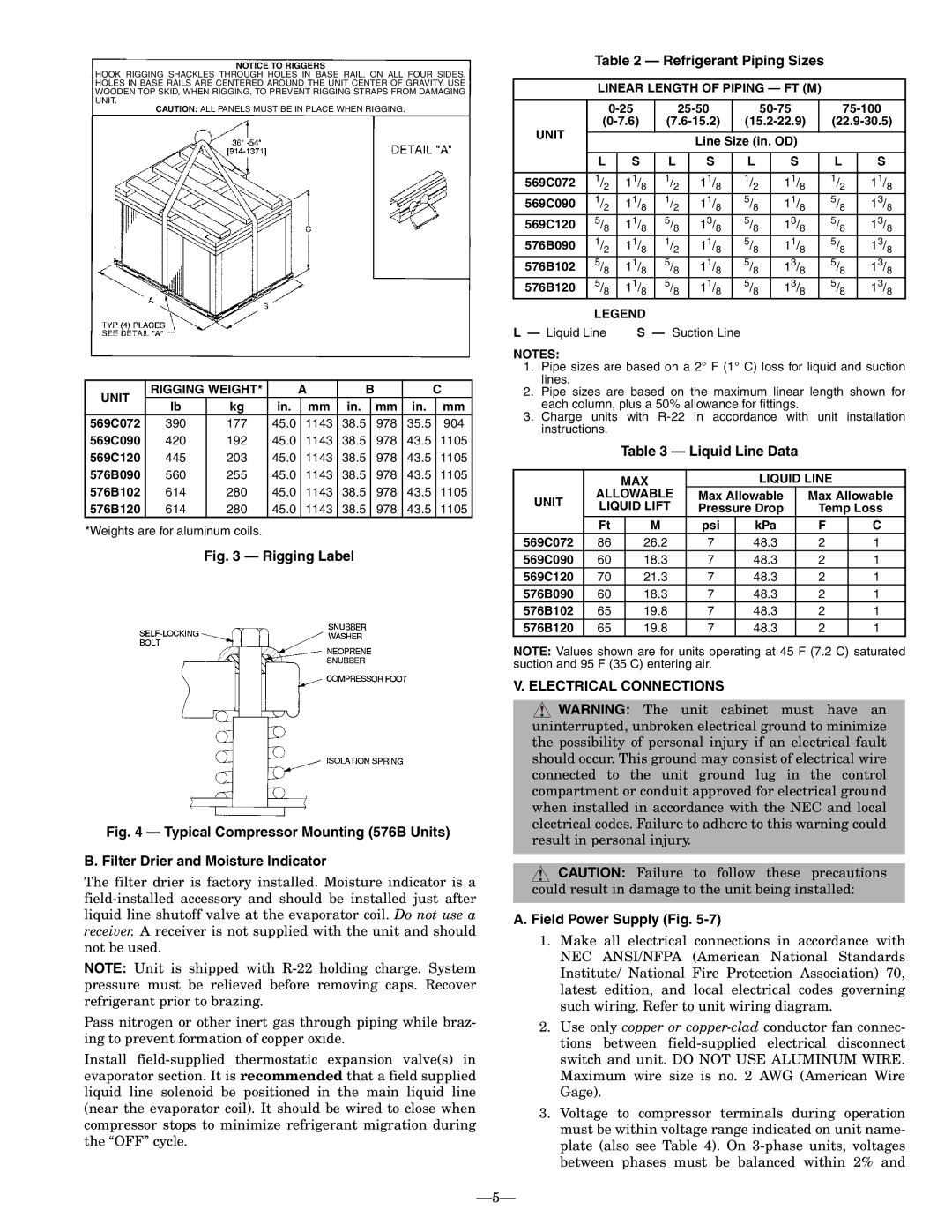

NOTICE TO RIGGERS

HOOK RIGGING SHACKLES THROUGH HOLES IN BASE RAIL, ON ALL FOUR SIDES. HOLES IN BASE RAILS ARE CENTERED AROUND THE UNIT CENTER OF GRAVITY. USE WOODEN TOP SKID, WHEN RIGGING, TO PREVENT RIGGING STRAPS FROM DAMAGING UNIT.

CAUTION: ALL PANELS MUST BE IN PLACE WHEN RIGGING.

UNIT | RIGGING WEIGHT* |

| A | B |

|

| C | |||||

lb | kg | in. | mm | in. | mm | in. | mm | |||||

| ||||||||||||

569C072 | 390 | 177 | 45.0 |

| 1143 | 38.5 |

| 978 | 35.5 |

| 904 | |

569C090 | 420 | 192 | 45.0 |

| 1143 | 38.5 |

| 978 | 43.5 |

| 1105 | |

569C120 | 445 | 203 | 45.0 |

| 1143 | 38.5 |

| 978 | 43.5 |

| 1105 | |

576B090 | 560 | 255 | 45.0 |

| 1143 | 38.5 |

| 978 | 43.5 |

| 1105 | |

576B102 | 614 | 280 | 45.0 |

| 1143 | 38.5 |

| 978 | 43.5 |

| 1105 | |

576B120 | 614 | 280 | 45.0 |

| 1143 | 38.5 |

| 978 | 43.5 |

| 1105 | |

*Weights are for aluminum coils.

Fig. 3 — Rigging Label

Fig. 4 — Typical Compressor Mounting (576B Units) B. Filter Drier and Moisture Indicator

The filter drier is factory installed. Moisture indicator is a

NOTE: Unit is shipped with

Pass nitrogen or other inert gas through piping while braz- ing to prevent formation of copper oxide.

Install

Table 2 — Refrigerant Piping Sizes

LINEAR LENGTH OF PIPING — FT (M)

|

|

|

|

|

|

| ||||||||

UNIT |

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| Line Size (in. OD) |

|

|

| |||||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| L | S | L | S |

|

| L |

| S | L | S |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

569C072 | 1/ | 2 | 11/ | 1/ | 11/ | 8 |

| 1/ | 2 |

| 11/ | 1/ | 11/ | 8 |

|

| 8 | 2 |

|

|

|

| 8 | 2 |

| ||||

569C090 | 1/ | 2 | 11/ | 1/ | 11/ | 8 |

| 5/ | 8 |

| 11/ | 5/ | 13/ | 8 |

|

| 8 | 2 |

|

|

|

| 8 | 8 |

| ||||

569C120 | 5/ | 8 | 11/ | 5/ | 13/ | 8 |

| 5/ | 8 |

| 13/ | 5/ | 13/ | 8 |

|

| 8 | 8 |

|

|

|

| 8 | 8 |

| ||||

576B090 | 1/ | 2 | 11/ | 1/ | 11/ | 8 |

| 5/ | 8 |

| 11/ | 5/ | 13/ | 8 |

|

| 8 | 2 |

|

|

|

| 8 | 8 |

| ||||

576B102 | 5/ | 8 | 11/ | 5/ | 11/ | 8 |

| 5/ | 8 |

| 13/ | 5/ | 13/ | 8 |

|

| 8 | 8 |

|

|

|

| 8 | 8 |

| ||||

576B120 | 5/ | 8 | 11/ | 5/ | 11/ | 8 |

| 5/ | 8 |

| 13/ | 5/ | 13/ | 8 |

|

| 8 | 8 |

|

|

|

| 8 | 8 |

| ||||

| LEGEND |

|

|

|

|

|

|

|

|

|

|

| ||

L — Liquid Line | S — Suction Line |

|

|

|

|

|

|

| ||||||

NOTES:

1.Pipe sizes are based on a 2° F (1° C) loss for liquid and suction lines.

2.Pipe sizes are based on the maximum linear length shown for each column, plus a 50% allowance for fittings.

3.Charge units with

Table 3 — Liquid Line Data

|

| MAX |

| LIQUID LINE |

| |||

UNIT | ALLOWABLE | Max Allowable | Max Allowable | |||||

LIQUID LIFT | Pressure Drop | Temp Loss | ||||||

| ||||||||

| Ft |

| M | psi | kPa | F | C | |

569C072 | 86 |

| 26.2 | 7 | 48.3 | 2 | 1 | |

569C090 | 60 |

| 18.3 | 7 | 48.3 | 2 | 1 | |

569C120 | 70 |

| 21.3 | 7 | 48.3 | 2 | 1 | |

576B090 | 60 |

| 18.3 | 7 | 48.3 | 2 | 1 | |

576B102 | 65 |

| 19.8 | 7 | 48.3 | 2 | 1 | |

576B120 | 65 |

| 19.8 | 7 | 48.3 | 2 | 1 | |

NOTE: Values shown are for units operating at 45 F (7.2 C) saturated suction and 95 F (35 C) entering air.

V. ELECTRICAL CONNECTIONS

![]() WARNING: The unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of personal injury if an electrical fault should occur. This ground may consist of electrical wire connected to the unit ground lug in the control compartment or conduit approved for electrical ground when installed in accordance with the NEC and local electrical codes. Failure to adhere to this warning could result in personal injury.

WARNING: The unit cabinet must have an uninterrupted, unbroken electrical ground to minimize the possibility of personal injury if an electrical fault should occur. This ground may consist of electrical wire connected to the unit ground lug in the control compartment or conduit approved for electrical ground when installed in accordance with the NEC and local electrical codes. Failure to adhere to this warning could result in personal injury.

![]() CAUTION: Failure to follow these precautions could result in damage to the unit being installed:

CAUTION: Failure to follow these precautions could result in damage to the unit being installed:

A.Field Power Supply (Fig. 5-7)

1.Make all electrical connections in accordance with NEC ANSI/NFPA (American National Standards Institute/ National Fire Protection Association) 70, latest edition, and local electrical codes governing such wiring. Refer to unit wiring diagram.

2.Use only copper or

3.Voltage to compressor terminals during operation must be within voltage range indicated on unit name- plate (also see Table 4). On