Cómo usar la

Clavadora (Continuación)

1.Desconecte la clavadora de la

fuente de sum- inistro de aire para lubricarla.

internas de la clavadora.

3. Use siempre mangueras de |

suministro de aire, con una presión |

mínima de funcionamiento con |

clasificación igual o mayor que la |

presión de la fuente de energía si |

falla un regulador, o 10,34 bar, lo |

que sea mayor. Use mangueras de |

aire de 9,5 mm (3/8") para distancias |

elemento de contacto antes de cada uso. El elemento de contacto se debe desplazar libremente, sin pegarse, a lo largo del área de desplazamiento. El resorte del elemento de contacto debe regresar el elemento de contacto a su posición original totalmente extendido. No use la clavadora si el mecanismo del elemento de contacto no está funcio- nando adecudamente. Podría ocasion- arle heridas.

Operating The Nailer

(Continued)

4.Push the maga- zine cover for-

ward until the latch catches.

5. Always unload all fasteners before |

removing tool from service. |

ADJUSTING THE DIRECTION OF THE EXHAUST

The nailer is | |

equipped with an | |

adjustable direc- | |

tion exhaust | |

deflector. This is | Rotate |

intended to allow | |

the user to change the direction of the exhaust. Simply twist the deflector to

7. Push button down

again to lift the

hook. Close the door and release

the button to

reengage the hook with the nose.

8. Make sure the trig- |

ger and work con- |

tact element (WCE) |

Agregue de 4 a 5

gotas de aceite sin detergente 30W en la entrada de aire. No use aceites con deter- gentes, aditivos de aceite, ni aceites para herramientas neumáticas. Los aceites para herramientas neumáti- cas contienen solventes que pueden averiar los componentes internos de la clavadora.

gotas de aceite sin detergente 30W en la entrada de aire. No use aceites con deter- gentes, aditivos de aceite, ni aceites para herramientas neumáticas. Los aceites para herramientas neumáti- cas contienen solventes que pueden averiar los componentes internos de la clavadora.

3.Después de agregar aceite, haga fun-

cionar la clavadora brevemente. Limpie todo exceso de

aceite que salga del escape de la tapa.

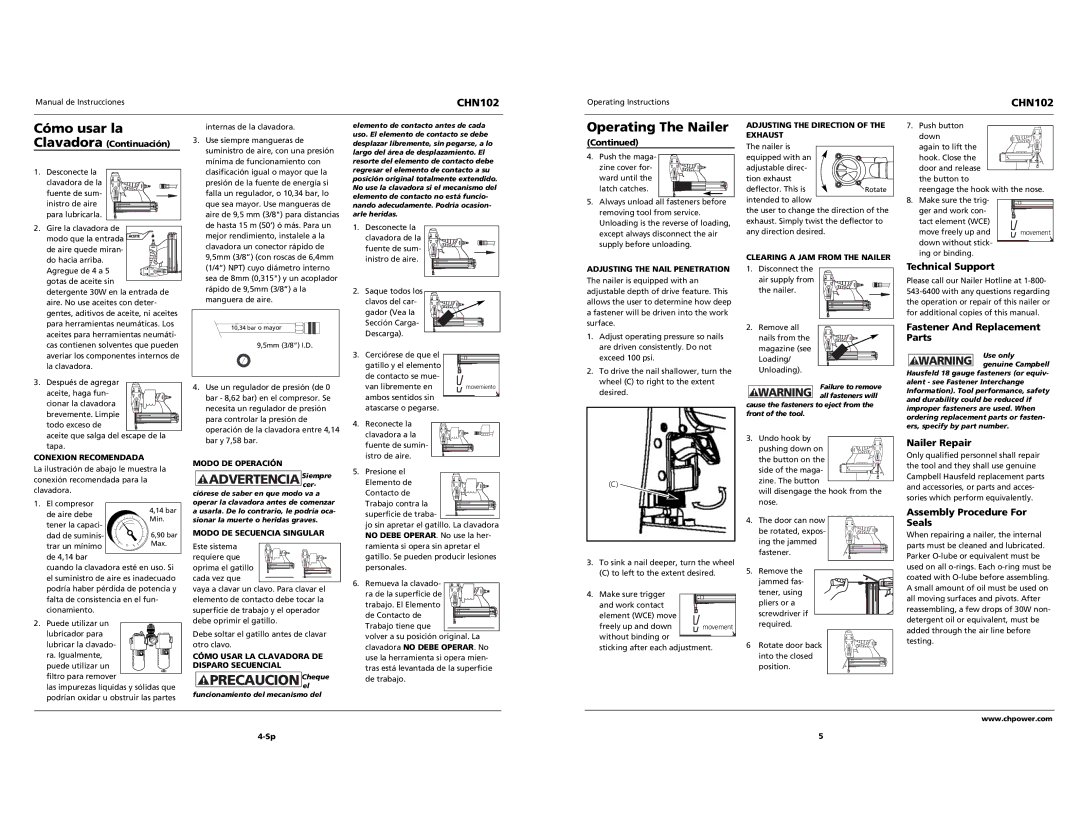

CONEXION RECOMENDADA

(1/4”) NPT) cuyo diámetro interno |

sea de 8mm (0,315") y un acoplador |

rápido de 9,5mm (3/8”) a la |

manguera de aire. |

10,34 bar o mayor

9,5mm (3/8”) I.D.

4.Use un regulador de presión (de 0 bar - 8,62 bar) en el compresor. Se necesita un regulador de presión para controlar la presión de operación de la clavadora entre 4,14 bar y 7,58 bar.

MODO DE OPERACIÓN

2.Saque todos los clavos del car-

gador (Vea la Sección Carga- Descarga).

3.Cerciórese de que el gatillo y el elemento de contacto se mue- van libremente en ambos sentidos sin atascarse o pegarse.

4.Reconecte la clavadora a la fuente de sumin- istro de aire.

ADJUSTING THE NAIL PENETRATION

The nailer is equipped with an adjustable depth of drive feature. This allows the user to determine how deep a fastener will be driven into the work surface.

1.Adjust operating pressure so nails are driven consistently. Do not exceed 100 psi.

2.To drive the nail shallower, turn the wheel (C) to right to the extent desired.

1.Disconnect the air supply from

the nailer.

2. | Remove all | |

| nails from the | |

| magazine (see | |

| Loading/ | |

| Unloading). | |

| ! WARNING | Failure to remove |

| all fasteners will |

cause the fasteners to eject from the |

front of the tool. | |

3. | Undo hook by | |

| pushing down on |

| the button on the |

Technical Support

Please call our Nailer Hotline at 1-800- 543-6400 with any questions regarding the operation or repair of this nailer or for additional copies of this manual.

Fastener And Replacement Parts

Use only

! WARNING genuine Campbell Hausfeld 18 gauge fasteners (or equiv- alent - see Fastener Interchange Information). Tool performance, safety and durability could be reduced if improper fasteners are used. When ordering replacement parts or fasten- ers, specify by part number.

Nailer Repair

Only qualified personnel shall repair the tool and they shall use genuine

!ADVERTENCIA Siemprecer-

ciórese de saber en que modo va a operar la clavadora antes de comenzar a usarla. De lo contrario, le podría oca- sionar la muerte o heridas graves.

MODO DE SECUENCIA SINGULAR

Este sistema requiere que

oprima el gatillo cada vez que

vaya a clavar un clavo. Para clavar el elemento de contacto debe tocar la superficie de trabajo y el operador debe oprimir el gatillo.

Debe soltar el gatillo antes de clavar otro clavo.

CÓMO USAR LA CLAVADORA DE DISPARO SECUENCIAL

!PRECAUCION Chequeel

funcionamiento del mecanismo del

5.Presione el Elemento de

Contacto de Trabajo contra la superficie de traba-

jo sin apretar el gatillo. La clavadora NO DEBE OPERAR. No use la her- ramienta si opera sin apretar el gatillo. Se pueden producir lesiones personales.

6.Remueva la clavado- ra de la superficie de trabajo. El Elemento de Contacto de Trabajo tiene que

volver a su posición original. La clavadora NO DEBE OPERAR. No use la herramienta si opera mien- tras está levantada de la superficie de trabajo.

(C)

3.To sink a nail deeper, turn the wheel

(C) to left to the extent desired.

4.Make sure trigger and work contact element (WCE) move

freely up and down | movement |

without binding or

sticking after each adjustment.

side of the maga- |

zine. The button |

will disengage the hook from the |

nose. |

4.The door can now be rotated, expos-

ing the jammed fastener.

5. Remove the jammed fas- tener, using pliers or a screwdriver if required.

6Rotate door back into the closed position.

Campbell Hausfeld replacement parts and accessories, or parts and acces- sories which perform equivalently.

Assembly Procedure For Seals

When repairing a nailer, the internal parts must be cleaned and lubricated. Parker O-lube or equivalent must be used on all o-rings. Each o-ring must be coated with O-lube before assembling. A small amount of oil must be used on all moving surfaces and pivots. After reassembling, a few drops of 30W non- detergent oil or equivalent, must be added through the air line before testing.