Portable Handheld Air Compressor

Wall Mounting (Cont.)

On the bottom of the compressor are two

Maintenance

! WARNING

Disconnect power source ![]()

![]()

![]()

![]()

![]() then release all pressure

then release all pressure ![]()

![]()

![]()

![]()

![]() from the system before attempting to install, service, relocate or perform any maintenance.

from the system before attempting to install, service, relocate or perform any maintenance.

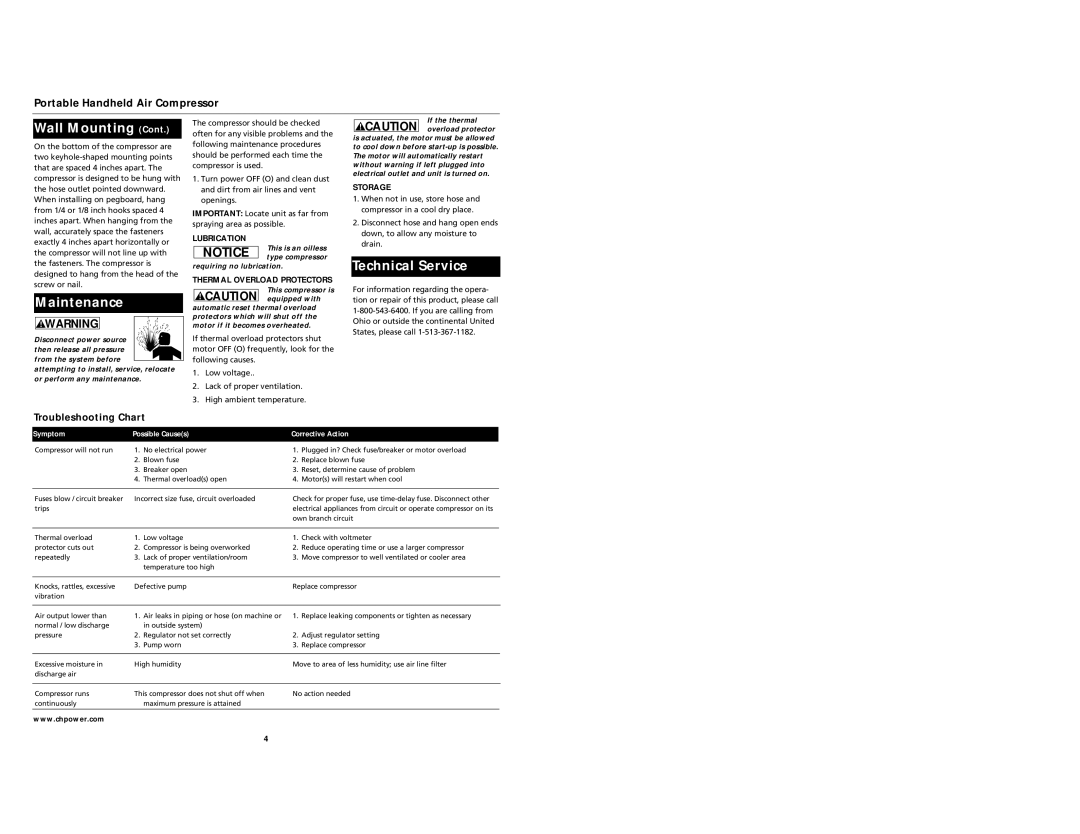

Troubleshooting Chart

The compressor should be checked often for any visible problems and the following maintenance procedures should be performed each time the compressor is used.

1.Turn power OFF (O) and clean dust and dirt from air lines and vent openings.

IMPORTANT: Locate unit as far from spraying area as possible.

LUBRICATION

NOTICE | This is an oilless | |

type compressor | ||

|

requiring no lubrication.

THERMAL OVERLOAD PROTECTORS

This compressor is

! CAUTION equipped with automatic reset thermal overload protectors which will shut off the motor if it becomes overheated.

If thermal overload protectors shut motor OFF (O) frequently, look for the following causes.

1.Low voltage..

2.Lack of proper ventilation.

3.High ambient temperature.

If the thermal

!CAUTION overload protector is actuated, the motor must be allowed to cool down before

STORAGE

1.When not in use, store hose and compressor in a cool dry place.

2.Disconnect hose and hang open ends down, to allow any moisture to drain.

Technical Service

For information regarding the opera- tion or repair of this product, please call

Symptom | Possible Cause(s) | Corrective Action |

| ||

Compressor will not run | 1. | No electrical power | 1. | Plugged in? Check fuse/breaker or motor overload |

|

| 2. | Blown fuse | 2. | Replace blown fuse |

|

| 3. | Breaker open | 3. | Reset, determine cause of problem |

|

| 4. | Thermal overload(s) open | 4. | Motor(s) will restart when cool |

|

|

|

|

| ||

Fuses blow / circuit breaker | Incorrect size fuse, circuit overloaded | Check for proper fuse, use |

| ||

trips |

|

| electrical appliances from circuit or operate compressor on its |

| |

|

|

| own branch circuit |

| |

|

|

|

|

|

|

Thermal overload | 1. | Low voltage | 1. | Check with voltmeter |

|

protector cuts out | 2. | Compressor is being overworked | 2. | Reduce operating time or use a larger compressor |

|

repeatedly | 3. | Lack of proper ventilation/room | 3. | Move compressor to well ventilated or cooler area |

|

|

| temperature too high |

|

|

|

|

|

|

| ||

Knocks, rattles, excessive | Defective pump | Replace compressor |

| ||

vibration |

|

|

|

|

|

|

|

|

|

|

|

Air output lower than | 1. | Air leaks in piping or hose (on machine or | 1. | Replace leaking components or tighten as necessary |

|

normal / low discharge |

| in outside system) |

|

|

|

pressure | 2. | Regulator not set correctly | 2. | Adjust regulator setting |

|

| 3. | Pump worn | 3. | Replace compressor |

|

|

|

|

| ||

Excessive moisture in | High humidity | Move to area of less humidity; use air line filter |

| ||

discharge air |

|

|

|

|

|

|

|

|

| ||

Compressor runs | This compressor does not shut off when | No action needed |

| ||

continuously |

| maximum pressure is attained |

|

|

|

|

|

|

|

|

|

www.chpower.com

4