Operating Instructions | Model PN0090 |

has been dropped or thrown, exam- ine the tool closely for bent, cracked or broken parts and air leaks. STOP and repair before using or serious injury could occur.

●Avoid long extended periods of work with the nailer. Stop using the nailer if you feel pain in hands or arms.

Caution indicates a

! CAUTION potentially haz- ardous situation which, if not avoided, MAY result in minor or moderate injury.

●Do not modify or alter the nailer or any nailer parts. Do not use the nailer if any shields or guards are removed or altered. Do not use the nailer as a hammer. Personal injury or tool damage may occur.

●Do not use a check valve or any other

fitting which allows air to remain in the nailer. Personal injury may occur.

●Never place hands or any other body parts in the nail discharge area of the nailer.

Use caution when placing a nail in the

nail guide. The nailer could eject the fastener causing personal injury.

●Never use the nailer as a toy. Do not engage in horseplay. Always keep others at a safe distance from the work area. Never point the nailer at anyone. Accidental triggering of the nailer could result in personal injury.

●Never leave the nailer unattended or connected to an air compressor when

not in use. Personal injury can occur if someone picks up and uses the nailer without knowing the correct way to operate the nailer.

Notice indicates NOTICE important infor-

mation, that if not followed, MAY cause damage to equipment.

●Inspect the tool daily for loose or broken parts. Do not use the tool until all parts have been tightened or replaced.

●Clean and check all air supply hoses and fittings before connecting the nailer to an air supply. Replace any damaged or worn hoses or fittings. Tool performance or durability may be reduced.

●Air compressors providing air to the nailer should follow the require- ments established by the American National Standards Institute Standard

Operating the Nailer

Read this manual and understand all safety warnings and instruc- tions before operating the nailer.

LUBRICATION

This nailer requires lubrication before using the nailer for the first time and before each use. If an inline oiler is used, manual lubrication through the air inlet is not required on a daily basis.

The work surface NOTICE can become dam-

aged by excessive lubrication. Proper lubrication is the owner’s responsibil- ity. Failure to lubricate the nailer prop- erly will dramatically shorten the life of the nailer and void the warranty.

1. Disconnect the air supply from the nailer to add lubricant.

2. Turn the nailer so |

| |

the air inlet is facing | OILOIL | |

up. Place | ||

| ||

of 30 W |

| |

gent oil into air inlet. |

| |

Do not use deter- |

| |

gent oils, oil addi- |

| |

tives, or air tool oils. Air tool oils | ||

contain solvents which will damage | ||

the nailer's internal components.

3.After adding oil, run nailer briefly. Wipe off any excess oil from the exhaust.

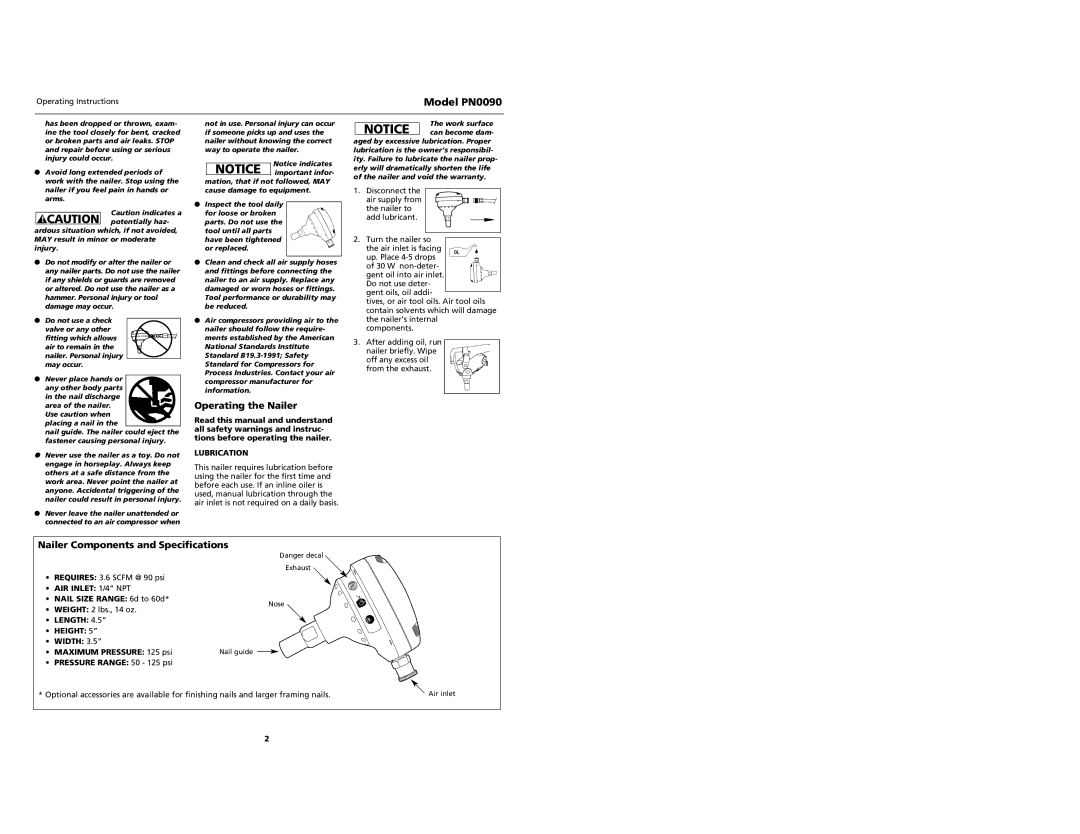

Nailer Components and Specifications

Danger decal

Exhaust

•REQUIRES: 3.6 SCFM @ 90 psi

• | AIR INLET: 1/4” NPT |

|

|

|

• | NAIL SIZE RANGE: 6d to 60d* |

| Nose | |

• | WEIGHT: 2 lbs., 14 oz. |

| ||

|

|

| ||

• | LENGTH: 4.5” |

|

|

|

• | HEIGHT: 5” |

|

|

|

• | WIDTH: 3.5” |

|

|

|

• | MAXIMUM PRESSURE: 125 psi | Nail guide |

|

|

| ||||

•PRESSURE RANGE: 50 - 125 psi

* Optional accessories are available for finishing nails and larger framing nails. | Air inlet |

2