BHC110, BHC90 specifications

Cannon is known for its innovative and high-performance products in the world of heating and cooling systems, and the BHC90 and BHC110 are prime examples of this legacy. These gas condensing boilers are designed to cater to both residential and commercial heating needs, delivering efficiency and reliability.The Cannon BHC90 has a maximum output of 90 kW, while the BHC110 boasts a higher capacity of 110 kW. Both models are engineered to provide optimal heating solutions, making them suitable for various applications, from small residential settings to larger commercial spaces. The compact design of these boilers allows for easy installation and integration into existing systems, saving valuable space without compromising on performance.

One of the standout features of the BHC series is the incorporation of advanced condensing technology. This technology allows the boilers to recover heat from exhaust gases, utilizing it to pre-heat incoming water. As a result, the systems achieve remarkable seasonal efficiencies, significantly reducing energy consumption and operating costs. The BHC90 and BHC110 can achieve efficiency ratings of up to 109%, an impressive benchmark in the industry.

In terms of user experience, both boilers are equipped with a user-friendly digital control interface. This feature allows homeowners and facility managers to monitor and adjust heating settings easily. Additionally, both models support compatibility with modern building management systems, providing seamless integration for enhanced operational control.

The BHC series also prioritizes safety and durability. They are designed with robust materials and advanced safety systems, including flame monitoring and pressure relief valves, ensuring reliable and worry-free operation. Their low NOx emissions contribute to reduced environmental impact and compliance with stringent regulations.

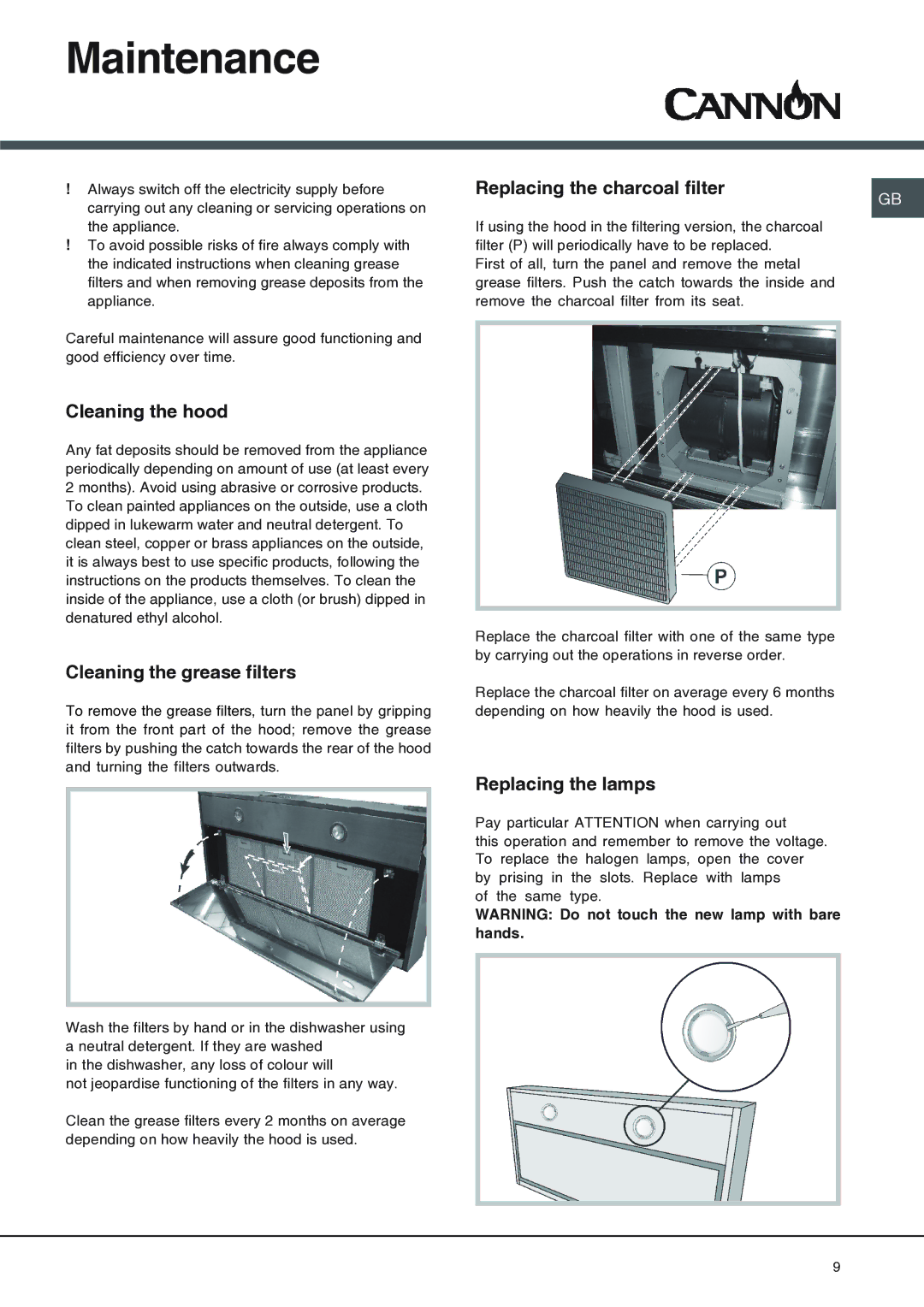

Maintenance is simplified with easy access to key components, ensuring that service and repairs can be conducted with minimal downtime. This longevity and reliability make the Cannon BHC90 and BHC110 excellent choices for those seeking efficient, high-capacity gas condensing boilers. Overall, the combination of advanced technologies, user-friendly features, and commitment to sustainability positions the Cannon BHC90 and BHC110 as leaders in the heating market.