PRE-START-UP

When charging, or when removing charge, circulate water through

Evacuate, Dehydrate, and Leak Test — The entire refrigerant system must be evacuated, dehydrated and leak test- ed by methods described in Carrier Standard Service Tech- niques Manual, Chapter 1, Section

Charge the system to a clear sight glass while holding saturated condensing pressure constant at 125 F

Oil Charge (See Tables 2 and 3) — All units are factory charged with oil. If oil is visible in sight glass, start compressor. Observe level and add oil, if required, to bring level in crankcase 1/8 to 3/8 of

operation. To add or remove oil, see Carrier Standard Service Techniques Manual, Chapter 1, Refrigerants.

IMPORTANT: Use only Carrier approved compressor oil. Do not reuse oil that has been drained and do not use oil that has been exposed to atmosphere.

Approved compressor oils*:

Petroleum Specialties, Inc. . . . . . . . . . . . . . . . . . . . . . Cryol 150 Texaco, Inc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Capella

*Approved for

TO ADD OIL — Close suction shutoff valve and pump down crankcase to 2 psig.

TO REMOVE OIL — Pump down compressor to 2 psig. Loosen the

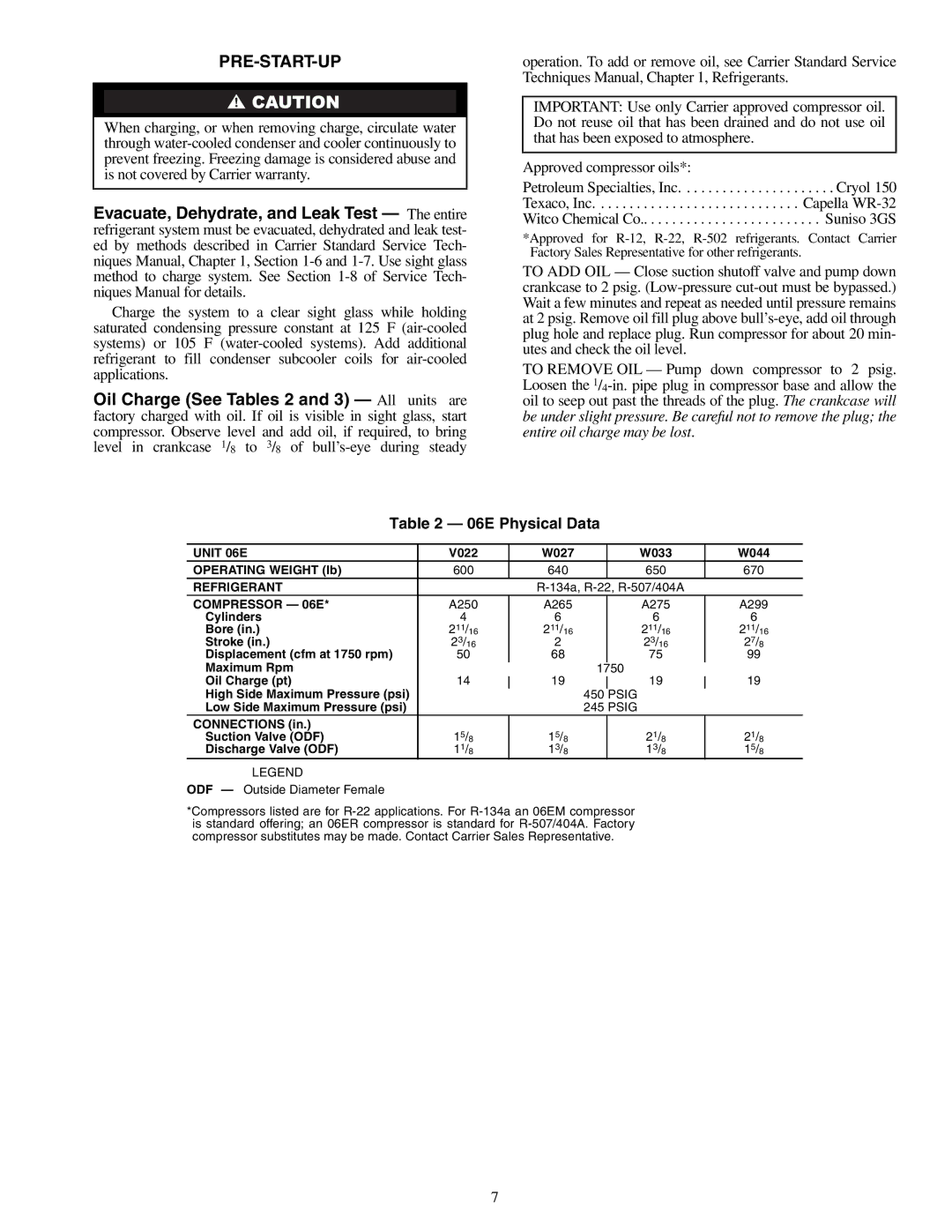

Table 2 — 06E Physical Data

UNIT 06E | V022 |

| W027 |

|

| W033 |

| W044 |

OPERATING WEIGHT (lb) | 600 |

| 640 |

|

| 650 |

| 670 |

REFRIGERANT |

|

|

|

| ||||

COMPRESSOR — 06E* | A250 |

| A265 |

|

| A275 |

| A299 |

Cylinders | 4 |

| 6 |

|

| 6 |

| 6 |

Bore (in.) | 211/16 |

| 211/16 |

|

| 211/16 |

| 211/16 |

Stroke (in.) | 23/16 |

| 2 |

|

| 23/16 |

| 27/8 |

Displacement (cfm at 1750 rpm) | 50 |

| 68 |

|

| 75 |

| 99 |

Maximum Rpm |

|

|

| 1750 |

|

| ||

Oil Charge (pt) | 14 |

| 19 |

|

| 19 |

| 19 |

|

|

| ||||||

High Side Maximum Pressure (psi) |

|

|

| 450 |

| PSIG |

|

|

Low Side Maximum Pressure (psi) |

|

|

| 245 PSIG |

|

| ||

CONNECTIONS (in.) |

|

|

|

|

|

|

|

|

Suction Valve (ODF) | 15/8 |

| 15/8 |

|

| 21/8 |

| 21/8 |

Discharge Valve (ODF) | 11/8 |

| 13/8 |

|

| 13/8 |

| 15/8 |

LEGEND

ODF — Outside Diameter Female

*Compressors listed are for

7