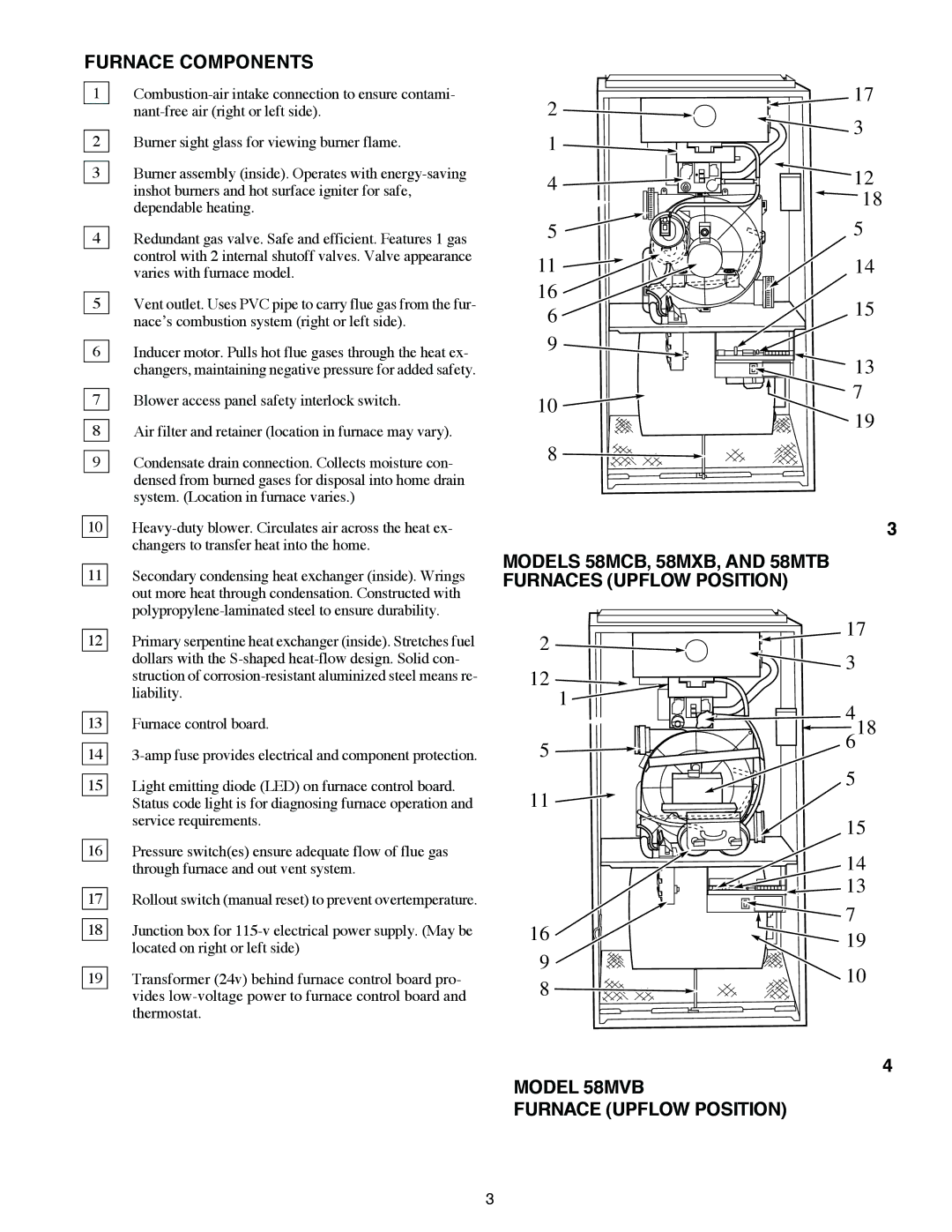

FURNACE COMPONENTS

1

2Burner sight glass for viewing burner flame.

3Burner assembly (inside). Operates with

4Redundant gas valve. Safe and efficient. Features 1 gas control with 2 internal shutoff valves. Valve appearance varies with furnace model.

5Vent outlet. Uses PVC pipe to carry flue gas from the fur- nace’s combustion system (right or left side).

6Inducer motor. Pulls hot flue gases through the heat ex- changers, maintaining negative pressure for added safety.

7Blower access panel safety interlock switch.

8Air filter and retainer (location in furnace may vary).

9Condensate drain connection. Collects moisture con- densed from burned gases for disposal into home drain system. (Location in furnace varies.)

10 | |

| changers to transfer heat into the home. |

|

|

11 | Secondary condensing heat exchanger (inside). Wrings |

| out more heat through condensation. Constructed with |

|

2 | 17 | |

3 | ||

1 | ||

| ||

4 | 12 | |

| 18 | |

5 | 5 | |

11 | 14 | |

16 | 15 | |

6 | ||

| ||

9 |

| |

| 13 | |

10 | 7 | |

19 | ||

| ||

8 |

|

3

MODELS 58MCB, 58MXB, AND 58MTB

FURNACES (UPFLOW POSITION)

12 | Primary serpentine heat exchanger (inside). Stretches fuel |

| dollars with the |

| struction of |

| liability. |

2 ![]()

12 ![]()

1

17

![]() 3

3

13 | Furnace control board. |

|

|

14 | |

|

|

15 | Light emitting diode (LED) on furnace control board. |

| Status code light is for diagnosing furnace operation and |

| service requirements. |

|

|

16 | Pressure switch(es) ensure adequate flow of flue gas |

| through furnace and out vent system. |

|

|

17 | Rollout switch (manual reset) to prevent overtemperature. |

|

|

18 | Junction box for |

| located on right or left side) |

|

|

19 | Transformer (24v) behind furnace control board pro- |

| vides |

| thermostat. |

| 4 |

5 | 618 |

| |

11 | 5 |

|

| 15 | |

| 14 | |

| 13 | |

16 | 7 | |

19 | ||

9 | ||

10 | ||

8 | ||

|

4

MODEL 58MVB

FURNACE (UPFLOW POSITION)

3