LP Cylinder Exchange

•Many retailers that sell this appliance offer you the option of replacing your empty LP cylinder through an exchange service. Use only those reputable exchange companies that inspect, precision fill, test and certify their cylinders. Exchange your cylinder only for an OPD safety

•Always keep new and exchanged LP cylinders in upright position during use, transit or storage.

•Leak test new and exchanged LP cylinders BEFORE connecting to the appliance.

•Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs may result in leakage of propane.

LP Cylinder Leak Test

For your safety

•Leak test must be repeated each time LP cylinder is exchanged or refilled.

•Do not smoke during leak test.

•Do not use an open flame to check for gas leaks.

•This appliance must be leak tested outdoors in a

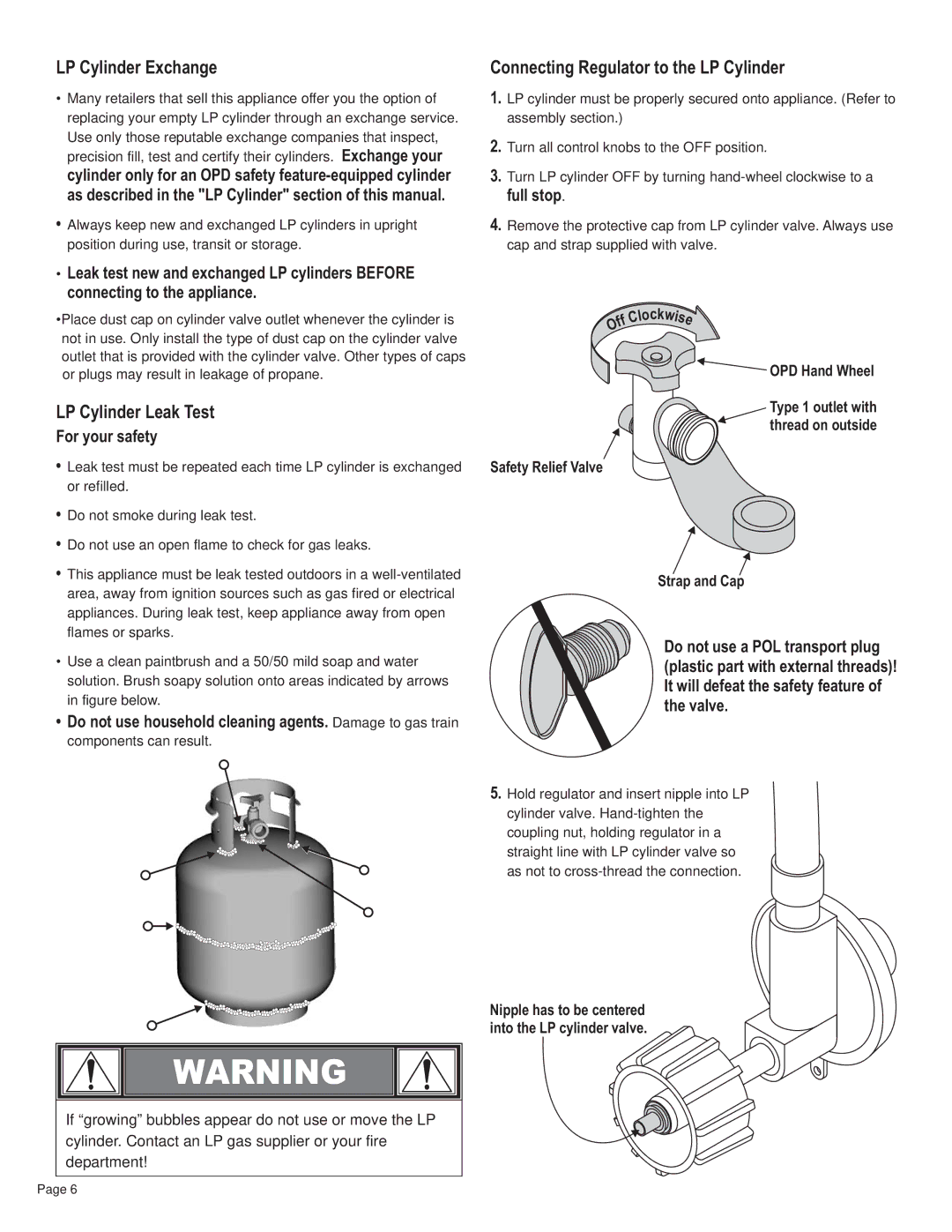

•Use a clean paintbrush and a 50/50 mild soap and water solution. Brush soapy solution onto areas indicated by arrows in figure below.

•Do not use household cleaning agents. Damage to gas train components can result.

WARNING |

If “growing” bubbles appear do not use or move the LP |

cylinder. Contact an LP gas supplier or your fire |

department! |

Connecting Regulator to the LP Cylinder

1.LP cylinder must be properly secured onto appliance. (Refer to assembly section.)

2.Turn all control knobs to the OFF position.

3.Turn LP cylinder OFF by turning

4.Remove the protective cap from LP cylinder valve. Always use cap and strap supplied with valve.

lo | ck |

|

wi | ||

ff C |

| se |

O |

|

|

OPD Hand Wheel

Type 1 outlet with thread on outside

Safety Relief Valve

Strap and Cap

Do not use a POL transport plug (plastic part with external threads)! It will defeat the safety feature of the valve.

5.Hold regulator and insert nipple into LP cylinder valve.

Nipple has to be centered into the LP cylinder valve.

Page 6