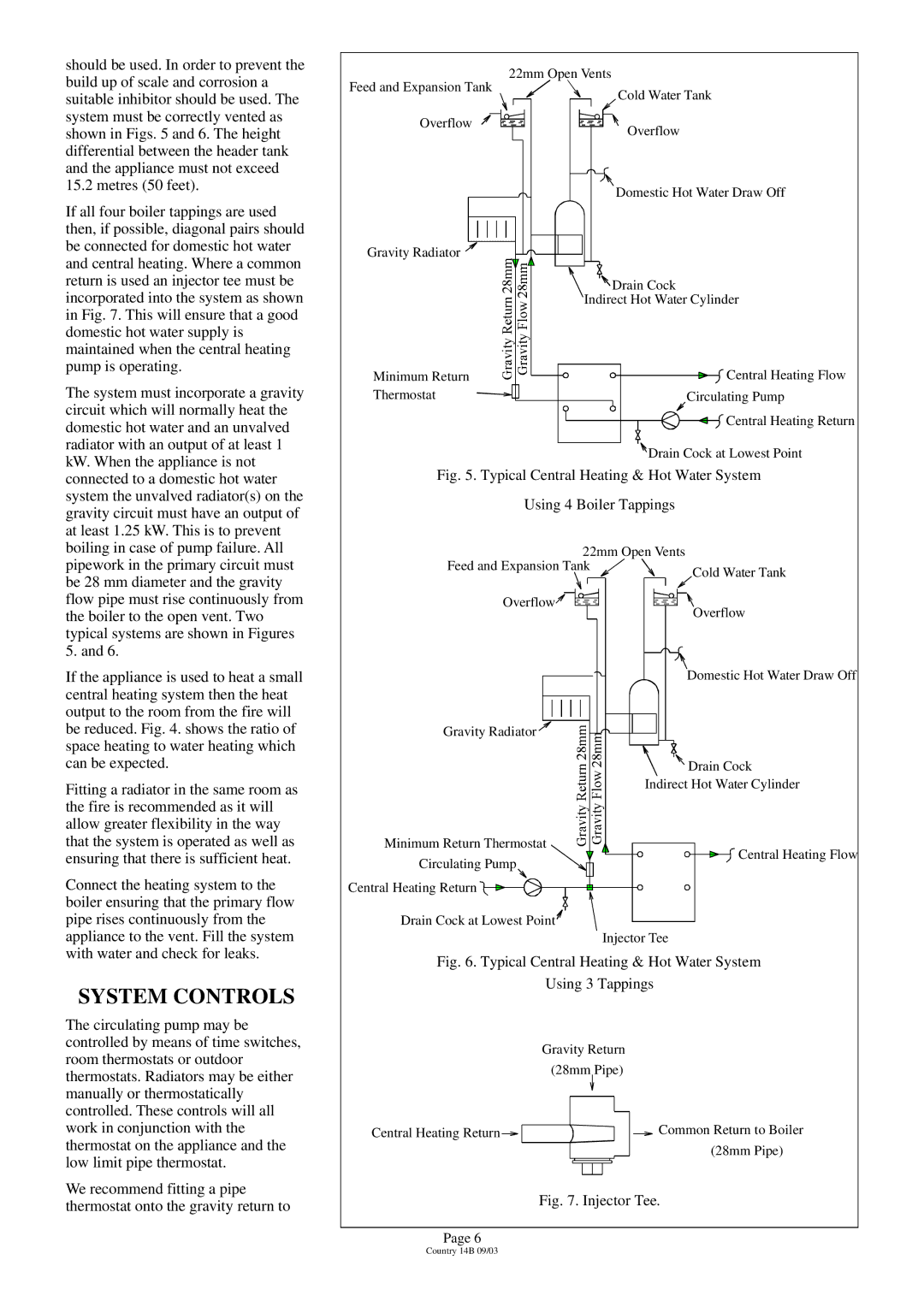

should be used. In order to prevent the build up of scale and corrosion a suitable inhibitor should be used. The system must be correctly vented as shown in Figs. 5 and 6. The height differential between the header tank and the appliance must not exceed 15.2 metres (50 feet).

If all four boiler tappings are used then, if possible, diagonal pairs should be connected for domestic hot water and central heating. Where a common return is used an injector tee must be incorporated into the system as shown in Fig. 7. This will ensure that a good domestic hot water supply is maintained when the central heating pump is operating.

The system must incorporate a gravity circuit which will normally heat the domestic hot water and an unvalved radiator with an output of at least 1 kW. When the appliance is not connected to a domestic hot water system the unvalved radiator(s) on the gravity circuit must have an output of at least 1.25 kW. This is to prevent boiling in case of pump failure. All pipework in the primary circuit must be 28 mm diameter and the gravity flow pipe must rise continuously from the boiler to the open vent. Two typical systems are shown in Figures 5. and 6.

If the appliance is used to heat a small central heating system then the heat output to the room from the fire will be reduced. Fig. 4. shows the ratio of space heating to water heating which can be expected.

Fitting a radiator in the same room as the fire is recommended as it will allow greater flexibility in the way that the system is operated as well as ensuring that there is sufficient heat.

Connect the heating system to the boiler ensuring that the primary flow pipe rises continuously from the appliance to the vent. Fill the system with water and check for leaks.

SYSTEM CONTROLS

The circulating pump may be controlled by means of time switches, room thermostats or outdoor thermostats. Radiators may be either manually or thermostatically controlled. These controls will all work in conjunction with the thermostat on the appliance and the low limit pipe thermostat.

We recommend fitting a pipe thermostat onto the gravity return to

22mm Open Vents

Feed and Expansion Tank

Cold Water Tank

Overflow

Overflow

Domestic Hot Water Draw Off

Gravity Radiator ![]()

![]() Drain Cock

Drain Cock

Indirect Hot Water Cylinder

Minimum Return | Central Heating Flow |

Thermostat | Circulating Pump |

![]() Central Heating Return

Central Heating Return

| Drain Cock at Lowest Point | |

Fig. 5. Typical Central Heating & Hot Water System | ||

Using 4 Boiler Tappings | ||

22mm Open Vents | ||

Feed and Expansion Tank | Cold Water Tank | |

| ||

Overflow | Overflow | |

| ||

| Domestic Hot Water Draw Off | |

Gravity Radiator |

| |

| Drain Cock | |

| Indirect Hot Water Cylinder | |

Minimum Return Thermostat | Central Heating Flow | |

Circulating Pump | ||

| ||

Central Heating Return |

| |

Drain Cock at Lowest Point

Injector Tee

Fig. 6. Typical Central Heating & Hot Water System

Using 3 Tappings

Gravity Return

(28mm Pipe)

Central Heating Return | Common Return to Boiler |

(28mm Pipe)

Fig. 7. Injector Tee.

Page 6

Country 14B 09/03