If an extension cord is used, it must have the following wire size: up to 30 feet, use 10 AWG size wire; 30 to 50 feet, use 8 AWG wire; Over 50 feet, use 6 AWG wire.

7.While holding the Torch Cable Clamp with electrode clearly out of the way of any grounded objects, turn the Power Switch to the ON position.

8.Orient yourself on the area to be welded, then place the Face Shield over your eyes.

Warning: Never look at the ignited arc without ANSI approved, arc shaded, eye protec- tion in a full face shield. Permanent eye damage or blindness can occur. Skin burns can occur. Never breath arc fumes.

9.Stroke the area to be welded with the electrode to ignite the arc.

Never tap the electrode into the welding surface to ignite the arc. This damages its external coating on the electrode which prevents oxygen in the air from coming into contact with the molten metal, causing it to oxidize.

10.Once the arc is ignited, tilt the electrode forward at an angle of approximately 30° and hold it at a distance from the welding object equal to the diameter of the electrode.

Note: If too much current is drawn from the Arc Welder, the Thermal Overload protector will activate, the amber indicator will light, and the Arc Welder will turn off until it cools down. If this happens, turn the Power Switch to the OFF position and wait about 20 minutes.

11.When the weld is complete, lift the electrode clearly away from any grounded object, set the Face Shield down and turn toward the Arc Welder and turn the Power Switch to the OFF position.

12.Remove the electrode from the Torch Cable Clamp.

13.Unplug the Power Cord from the electrical outlet.

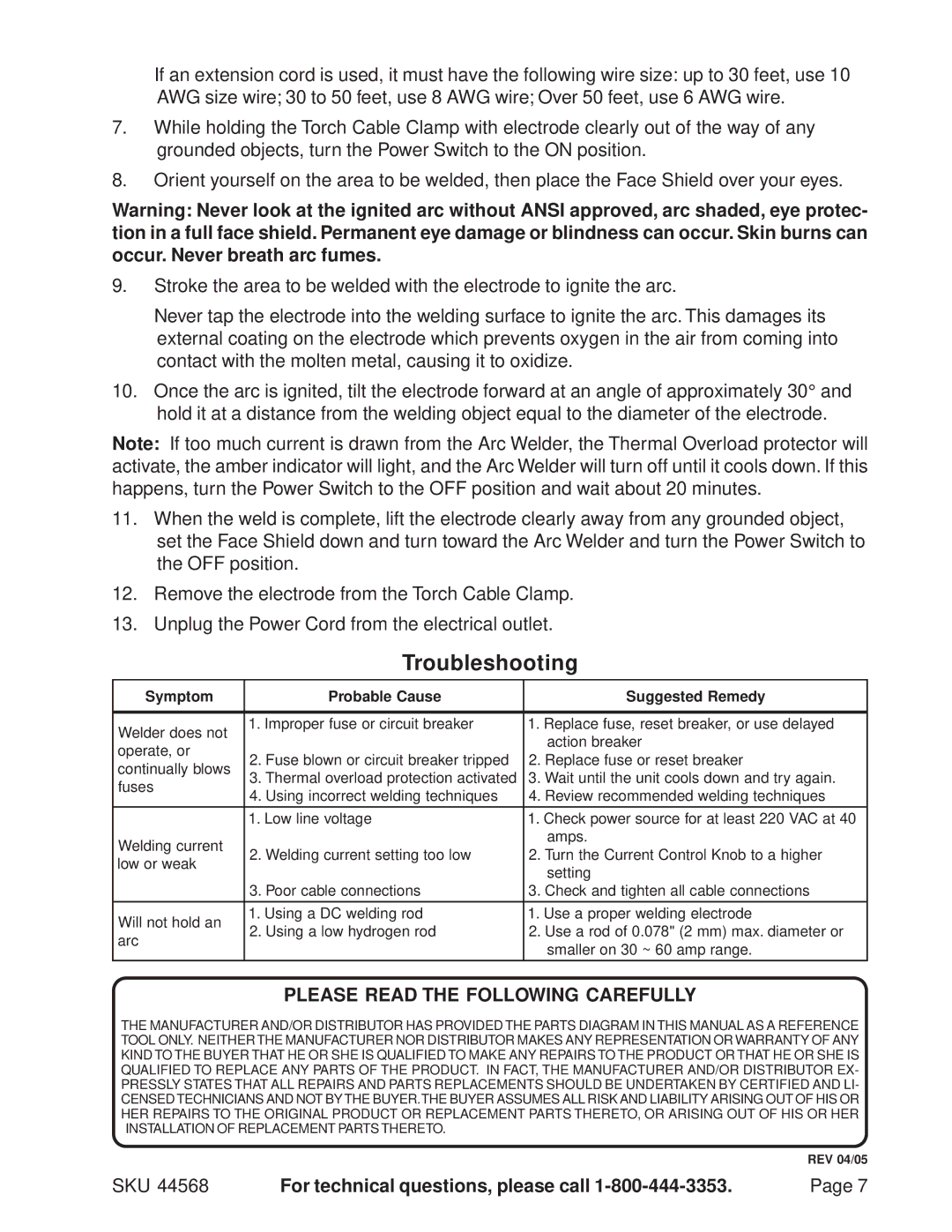

Troubleshooting

Symptom |

| Probable Cause | Suggested Remedy | |

|

|

|

| |

Welder does not | 1. | Improper fuse or circuit breaker | 1. Replace fuse, reset breaker, or use delayed | |

|

| action breaker | ||

operate, or |

|

| ||

2. Fuse blown or circuit breaker tripped | 2. Replace fuse or reset breaker | |||

continually blows | ||||

3. Thermal overload protection activated | 3. Wait until the unit cools down and try again. | |||

fuses | ||||

4. Using incorrect welding techniques | 4. Review recommended welding techniques | |||

| ||||

|

|

| ||

| 1. Low line voltage | 1. Check power source for at least 220 VAC at 40 | ||

Welding current |

|

| amps. | |

2. Welding current setting too low | 2. Turn the Current Control Knob to a higher | |||

low or weak | ||||

|

| setting | ||

|

|

| ||

| 3. Poor cable connections | 3. Check and tighten all cable connections | ||

Will not hold an | 1. Using a DC welding rod | 1. Use a proper welding electrode | ||

2. Using a low hydrogen rod | 2. Use a rod of 0.078" (2 mm) max. diameter or | |||

arc | ||||

|

| smaller on 30 ~ 60 amp range. | ||

|

|

| ||

|

|

|

| |

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EX- PRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LI- CENSED TECHNICIANS AND NOT BY THE BUYER.THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

REV 04/05

SKU 44568 | For technical questions, please call | Page 7 |