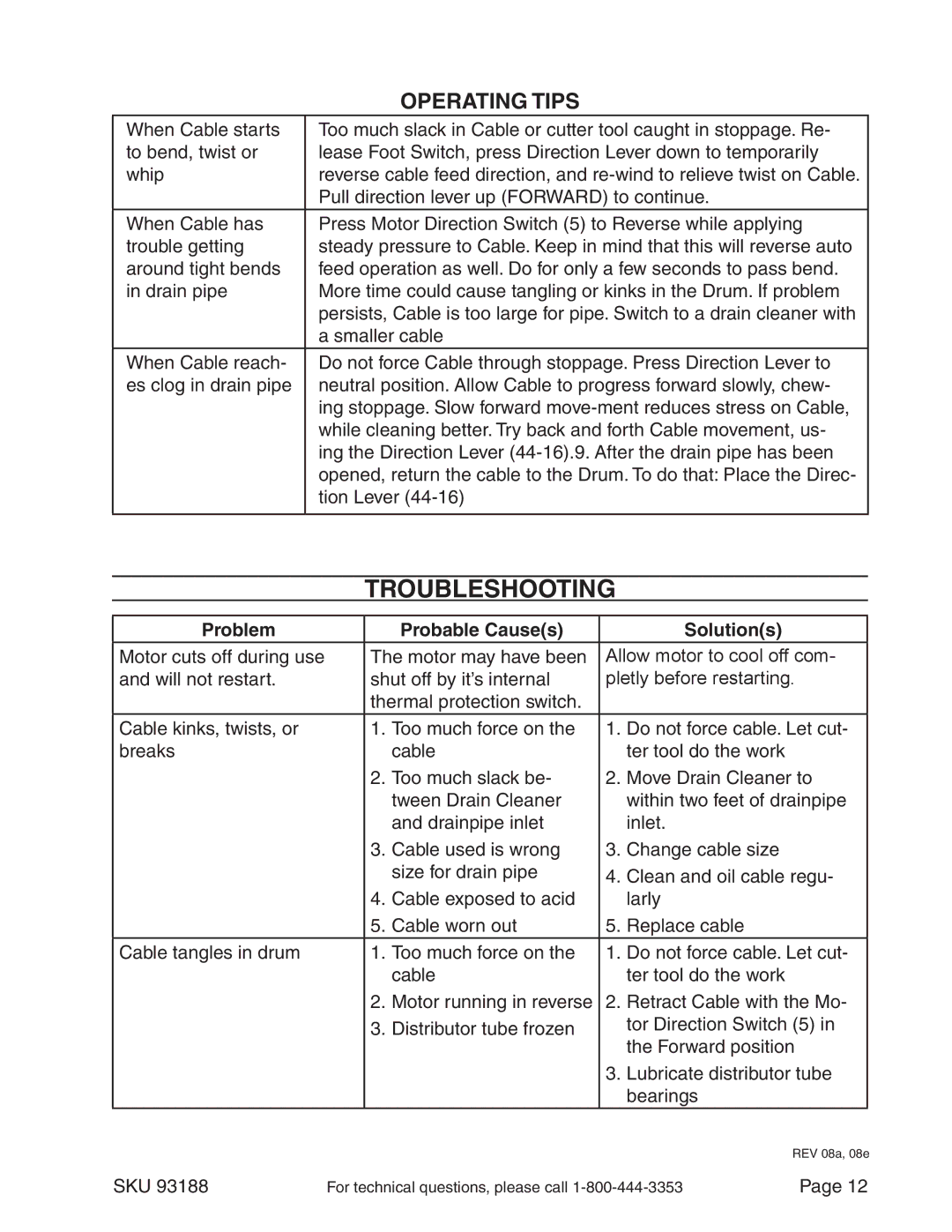

| OPERATING TIPS |

When Cable starts | Too much slack in Cable or cutter tool caught in stoppage. Re- |

to bend, twist or | lease Foot Switch, press Direction Lever down to temporarily |

whip | reverse cable feed direction, and |

| Pull direction lever up (FORWARD) to continue. |

When Cable has | Press Motor Direction Switch (5) to Reverse while applying |

trouble getting | steady pressure to Cable. Keep in mind that this will reverse auto |

around tight bends | feed operation as well. Do for only a few seconds to pass bend. |

in drain pipe | More time could cause tangling or kinks in the Drum. If problem |

| persists, Cable is too large for pipe. Switch to a drain cleaner with |

| a smaller cable |

When Cable reach- | Do not force Cable through stoppage. Press Direction Lever to |

es clog in drain pipe | neutral position. Allow Cable to progress forward slowly, chew- |

| ing stoppage. Slow forward |

| while cleaning better. Try back and forth Cable movement, us- |

| ing the Direction Lever |

| opened, return the cable to the Drum. To do that: Place the Direc- |

| tion Lever |

|

|

Troubleshooting

Problem |

| Probable Cause(s) |

| Solution(s) |

|

Motor cuts off during use | The motor may have been | Allow motor to cool off com- |

| ||

and will not restart. | shut off by it’s internal | pletly before restarting. |

| ||

| thermal protection switch. |

|

|

| |

Cable kinks, twists, or | 1. Too much force on the | 1. | Do not force cable. Let cut- |

| |

breaks |

| cable |

| ter tool do the work |

|

| 2. | Too much slack be- | 2. | Move Drain Cleaner to |

|

|

| tween Drain Cleaner |

| within two feet of drainpipe |

|

|

| and drainpipe inlet |

| inlet. |

|

| 3. | Cable used is wrong | 3. | Change cable size |

|

|

| size for drain pipe | 4. | Clean and oil cable regu- |

|

| 4. | Cable exposed to acid |

| larly |

|

| 5. | Cable worn out | 5. | Replace cable |

|

Cable tangles in drum | 1. Too much force on the | 1. | Do not force cable. Let cut- |

| |

|

| cable |

| ter tool do the work |

|

| 2. | Motor running in reverse | 2. | Retract Cable with the Mo- |

|

| 3. | Distributor tube frozen |

| tor Direction Switch (5) in |

|

|

|

|

| the Forward position |

|

|

|

| 3. | Lubricate distributor tube |

|

|

|

|

| bearings |

|

|

|

|

| REV 08a, 08e | |

SKU 93188 | For technical questions, please call | Page 12 |