(4), and unplug the tool from its electrical outlet before performing inspection, maintenance, or cleaning procedures.

Damaged equipment can fail, causing personal injury. Do not use damaged equipment. If abnormal noise or vibration occurs, have the problem corrected before further use.

Cleaning, maintenance, and lubrication

1.BEFORE EACH USE, inspect the general condition of the tool. Check for dam- aged Soldering Iron (15) tip, loose screws, cracked or broken parts, damaged electrical wiring, and any other condition that may affect its safe operation.

2.After Use, clean external surfaces and Soldering Tip.

3.WARNING! If the supply cord of this power tool is damaged, it must be replaced only by a qualified service technician.

Replacing the Soldering Iron

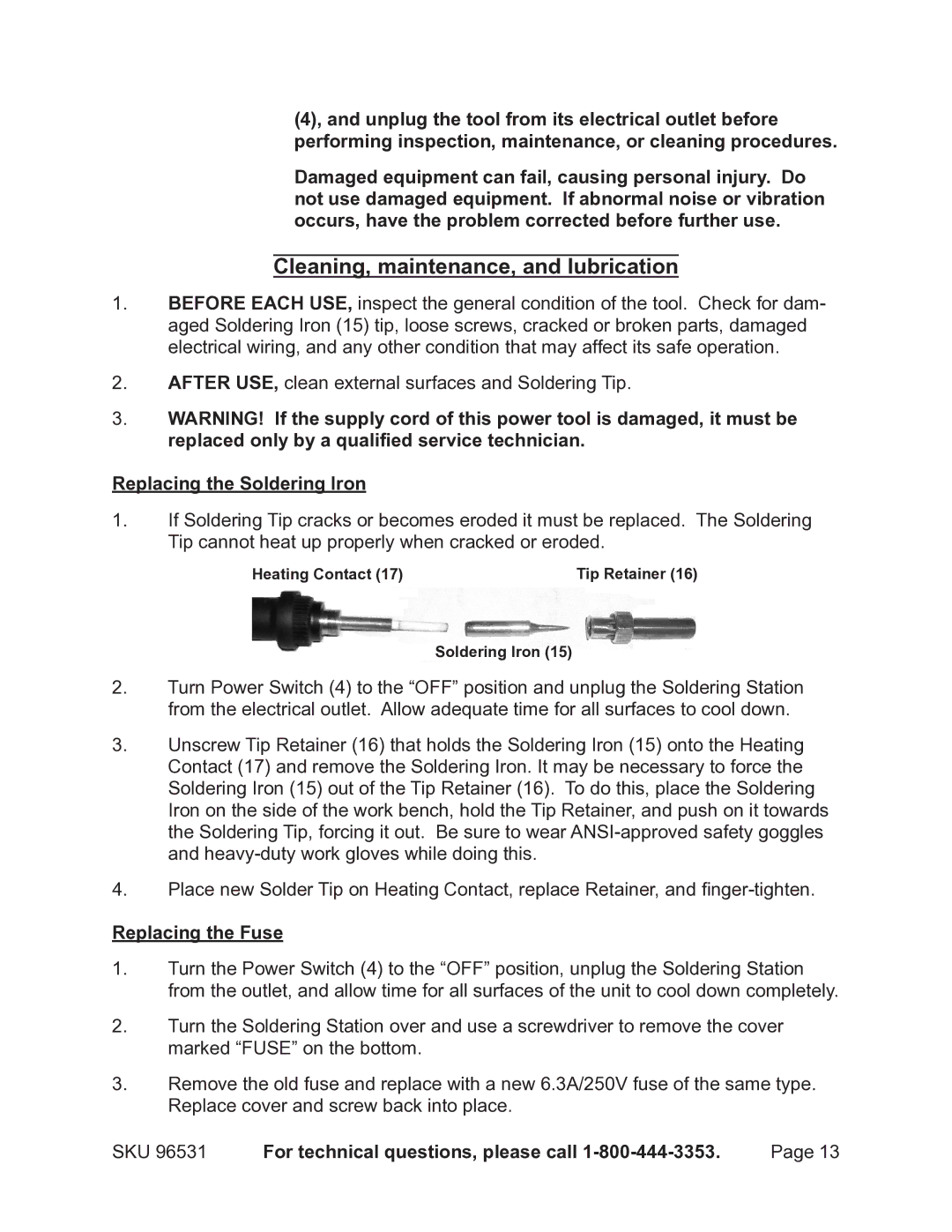

1.If Soldering Tip cracks or becomes eroded it must be replaced. The Soldering Tip cannot heat up properly when cracked or eroded.

Heating Contact (17) | Tip Retainer (16) |

Soldering Iron (15)

2.Turn Power Switch (4) to the “OFF” position and unplug the Soldering Station from the electrical outlet. Allow adequate time for all surfaces to cool down.

3.Unscrew Tip Retainer (16) that holds the Soldering Iron (15) onto the Heating Contact (17) and remove the Soldering Iron. It may be necessary to force the Soldering Iron (15) out of the Tip Retainer (16). To do this, place the Soldering Iron on the side of the work bench, hold the Tip Retainer, and push on it towards the Soldering Tip, forcing it out. Be sure to wear

4.Place new Solder Tip on Heating Contact, replace Retainer, and

Replacing the Fuse

1.Turn the Power Switch (4) to the “OFF” position, unplug the Soldering Station from the outlet, and allow time for all surfaces of the unit to cool down completely.

2.Turn the Soldering Station over and use a screwdriver to remove the cover marked “FUSE” on the bottom.

3.Remove the old fuse and replace with a new 6.3A/250V fuse of the same type. Replace cover and screw back into place.

SKU 96531 | For technical questions, please call | Page 13 |