OPERATING INSTRUCTIONS

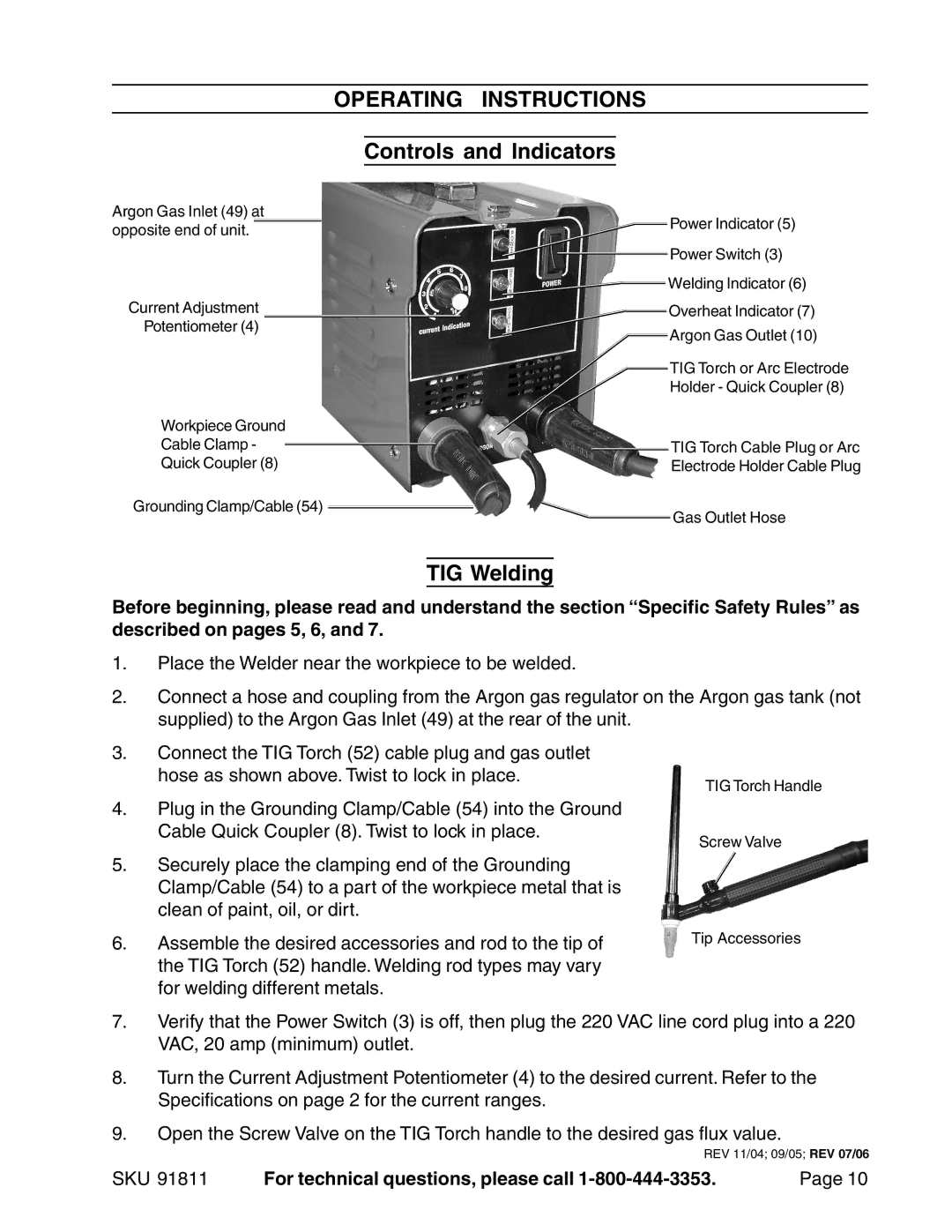

Controls and Indicators

Argon Gas Inlet (49) at opposite end of unit.

Current Adjustment

Potentiometer (4)

Workpiece Ground

Cable Clamp -

Quick Coupler (8)

Grounding Clamp/Cable (54)

Power Indicator (5)

Power Switch (3)

![]() Welding Indicator (6) Overheat Indicator (7)

Welding Indicator (6) Overheat Indicator (7)

Argon Gas Outlet (10)

TIG Torch or Arc Electrode

Holder - Quick Coupler (8)

TIG Torch Cable Plug or Arc

Electrode Holder Cable Plug

![]()

![]() Gas Outlet Hose

Gas Outlet Hose

TIG Welding

Before beginning, please read and understand the section “Specific Safety Rules” as described on pages 5, 6, and 7.

1.Place the Welder near the workpiece to be welded.

2.Connect a hose and coupling from the Argon gas regulator on the Argon gas tank (not supplied) to the Argon Gas Inlet (49) at the rear of the unit.

3.Connect the TIG Torch (52) cable plug and gas outlet hose as shown above. Twist to lock in place.

4.Plug in the Grounding Clamp/Cable (54) into the Ground Cable Quick Coupler (8). Twist to lock in place.

5.Securely place the clamping end of the Grounding Clamp/Cable (54) to a part of the workpiece metal that is clean of paint, oil, or dirt.

6.Assemble the desired accessories and rod to the tip of the TIG Torch (52) handle. Welding rod types may vary for welding different metals.

TIG Torch Handle

Screw Valve

Tip Accessories

7.Verify that the Power Switch (3) is off, then plug the 220 VAC line cord plug into a 220 VAC, 20 amp (minimum) outlet.

8.Turn the Current Adjustment Potentiometer (4) to the desired current. Refer to the Specifications on page 2 for the current ranges.

9.Open the Screw Valve on the TIG Torch handle to the desired gas flux value.

REV 11/04; 09/05; REV 07/06

SKU 91811 | For technical questions, please call | Page 10 |