Installation Instructions | CMA351 | |

7. | Using a pipe wrench, install | |

| ANSI/ASME B1.20.1 (Schedule 40, 0.154" minimum | |

| thickness aluminum - ASTM B221) threaded extension | |

| column (not included) into swivel adapter (A) until tight, with | |

| a minimum of four threads engaged. |

|

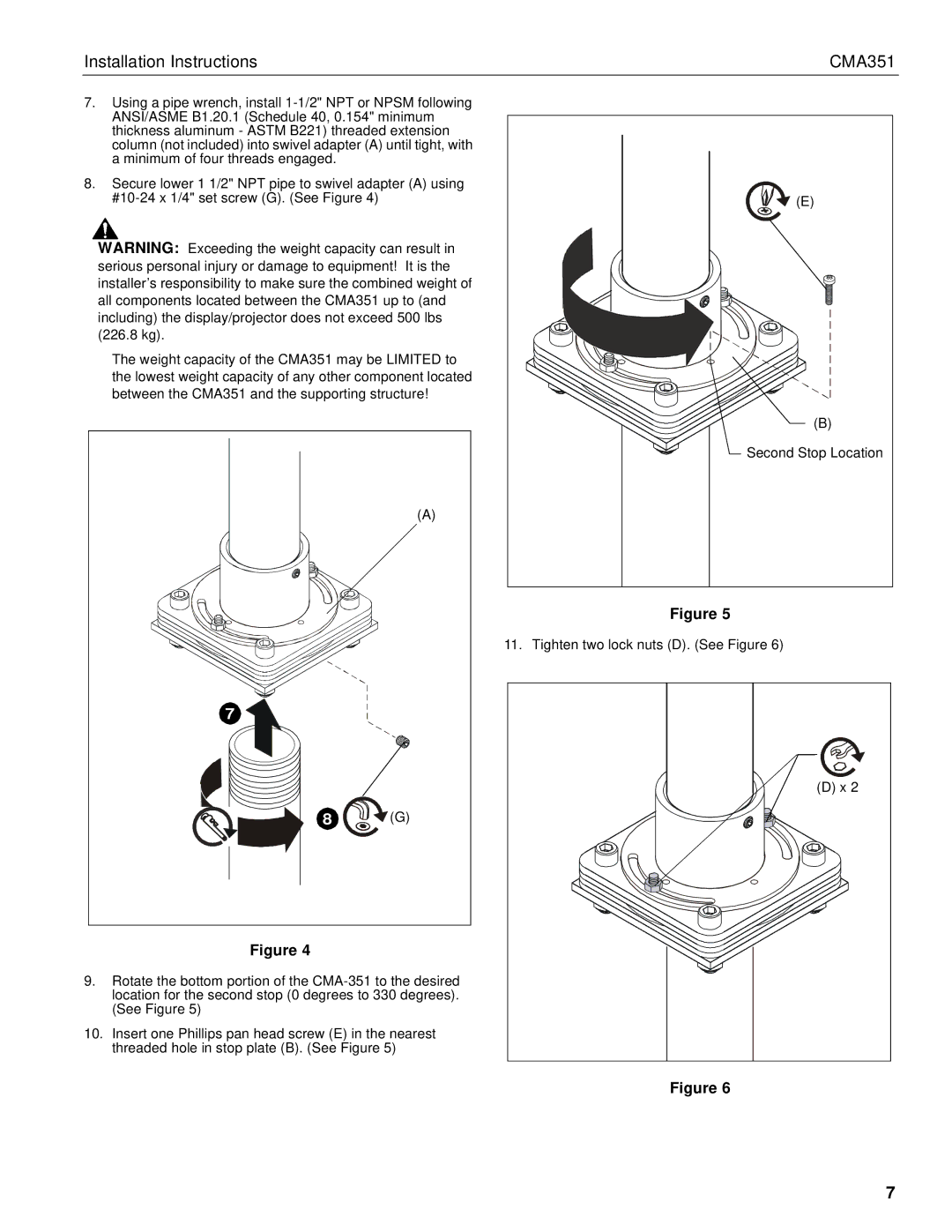

8. | Secure lower 1 1/2" NPT pipe to swivel adapter (A) using | |

| (E) | |

WARNING: Exceeding the weight capacity can result in | ||

serious personal injury or damage to equipment! It is the | ||

installer’s responsibility to make sure the combined weight of | ||

all components located between the CMA351 up to (and | ||

including) the display/projector does not exceed 500 lbs | ||

(226.8 kg). |

| |

| The weight capacity of the CMA351 may be LIMITED to | |

| the lowest weight capacity of any other component located | |

| between the CMA351 and the supporting structure! | |

|

| (B) |

|

| Second Stop Location |

|

| (A) |

|

| Figure 5 |

|

| 11. Tighten two lock nuts (D). (See Figure 6) |

| 7 |

|

|

| (D) x 2 |

| 8 | (G) |

| Figure 4 |

|

9. | Rotate the bottom portion of the | |

| location for the second stop (0 degrees to 330 degrees). | |

| (See Figure 5) |

|

10. | Insert one Phillips pan head screw (E) in the nearest | |

| threaded hole in stop plate (B). (See Figure 5) | |

Figure 6

7