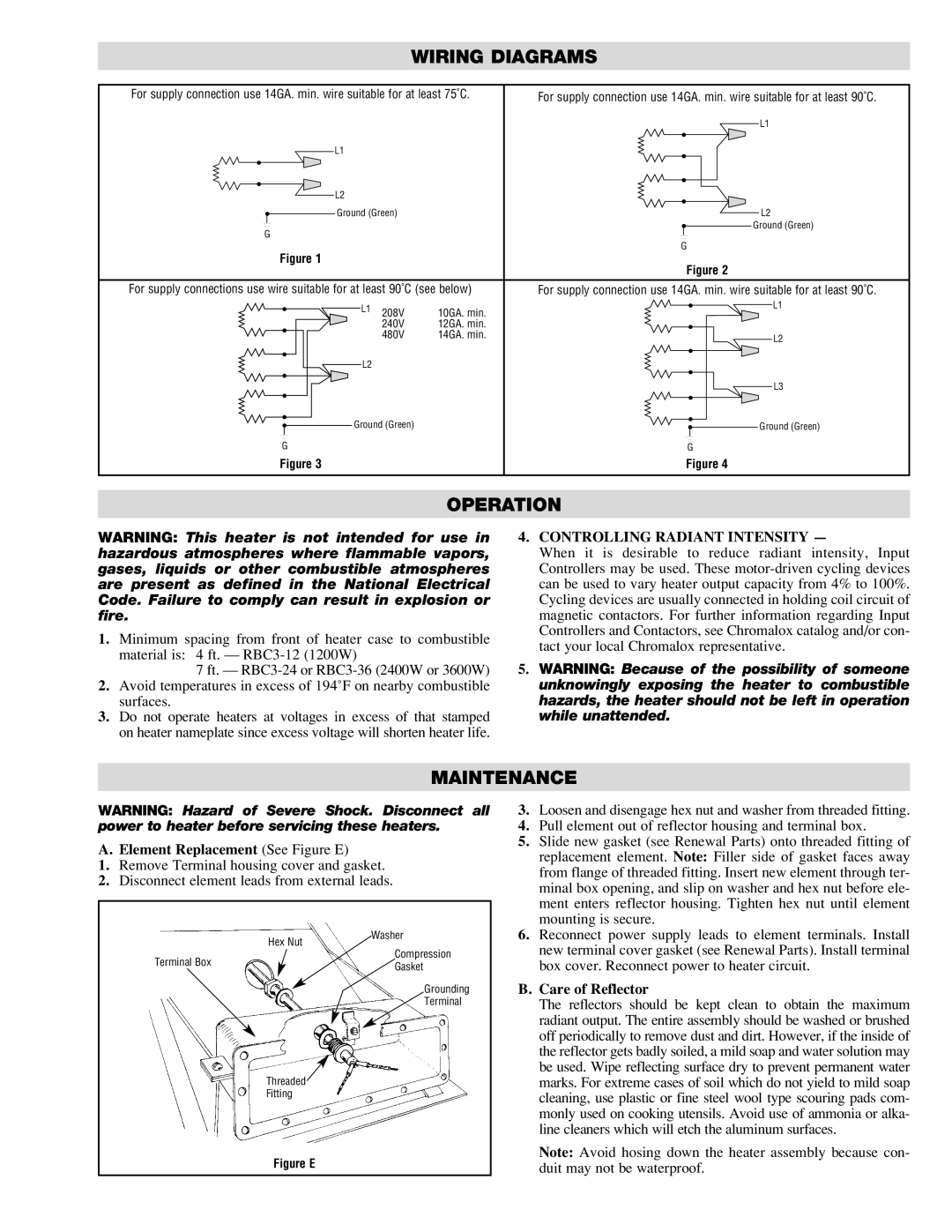

WIRING DIAGRAMS

For supply connection use 14GA. min. wire suitable for at least 75˚C. | For supply connection use 14GA. min. wire suitable for at least 90˚C. | ||

|

|

| L1 |

L1 |

|

|

|

L2 |

|

|

|

Ground (Green) |

| L2 | |

G |

|

| Ground (Green) |

|

|

| |

Figure 1 |

|

| G |

|

| Figure 2 | |

|

|

| |

For supply connections use wire suitable for at least 90˚C (see below) | For supply connection use 14GA. min. wire suitable for at least 90˚C. | ||

L1 | 208V | 10GA. min. | L1 |

| |||

| 240V | 12GA. min. |

|

| 480V | 14GA. min. | L2 |

|

|

| |

L2 |

|

|

|

|

|

| L3 |

Ground (Green) |

| Ground (Green) | |

G |

|

| G |

Figure 3 |

|

| Figure 4 |

OPERATION

WARNING: This heater is not intended for use in hazardous atmospheres where flammable vapors, gases, liquids or other combustible atmospheres are present as defined in the National Electrical Code. Failure to comply can result in explosion or fire.

1.Minimum spacing from front of heater case to combustible material is: 4 ft. —

7 ft. —

2.Avoid temperatures in excess of 194˚F on nearby combustible surfaces.

3.Do not operate heaters at voltages in excess of that stamped on heater nameplate since excess voltage will shorten heater life.

4.CONTROLLING RADIANT INTENSITY —

When it is desirable to reduce radiant intensity, Input Controllers may be used. These

5.WARNING: Because of the possibility of someone unknowingly exposing the heater to combustible hazards, the heater should not be left in operation while unattended.

MAINTENANCE

WARNING: Hazard of Severe Shock. Disconnect all power to heater before servicing these heaters.

A. Element Replacement (See Figure E)

1.Remove Terminal housing cover and gasket.

2.Disconnect element leads from external leads.

| Hex Nut | Washer |

| Compression | |

Terminal Box |

| |

| Gasket | |

|

| |

|

| Grounding |

|

| Terminal |

Threaded![]()

Fitting

Figure E

3.Loosen and disengage hex nut and washer from threaded fitting.

4.Pull element out of reflector housing and terminal box.

5.Slide new gasket (see Renewal Parts) onto threaded fitting of replacement element. Note: Filler side of gasket faces away from flange of threaded fitting. Insert new element through ter- minal box opening, and slip on washer and hex nut before ele- ment enters reflector housing. Tighten hex nut until element mounting is secure.

6.Reconnect power supply leads to element terminals. Install new terminal cover gasket (see Renewal Parts). Install terminal box cover. Reconnect power to heater circuit.

B.Care of Reflector

The reflectors should be kept clean to obtain the maximum radiant output. The entire assembly should be washed or brushed off periodically to remove dust and dirt. However, if the inside of the reflector gets badly soiled, a mild soap and water solution may be used. Wipe reflecting surface dry to prevent permanent water marks. For extreme cases of soil which do not yield to mild soap cleaning, use plastic or fine steel wool type scouring pads com- monly used on cooking utensils. Avoid use of ammonia or alka- line cleaners which will etch the aluminum surfaces.

Note: Avoid hosing down the heater assembly because con- duit may not be waterproof.