FAN SPEED ADJUSTMENTS

Changing the Pitch Diameter of the Sheaves:

1.Tools required: 5/32” allen wrench, 3/8” nut driver, 9/16” box wrench and a medium size phillips screwdriver.

2.Remove the lower belt cover by removing the (5) sheet metal screws.

3.Remove the rear grille by removing the (4) 1/4” bolts and nuts.

4.Remove the belt cover inside the blower by removing the (4) sheet metal screws.

5.Loosen the (4) bolts, (2) on each side. See Fig. 1.

Figure 1

3/8” Bolts

6.Loosen the (2) motor tension lock nuts and the fan belt tension adjusting bolts. See Fig.2

3/8” Bolts

Figure 2

Lock Nuts

Fan belt tension adjusting bolts

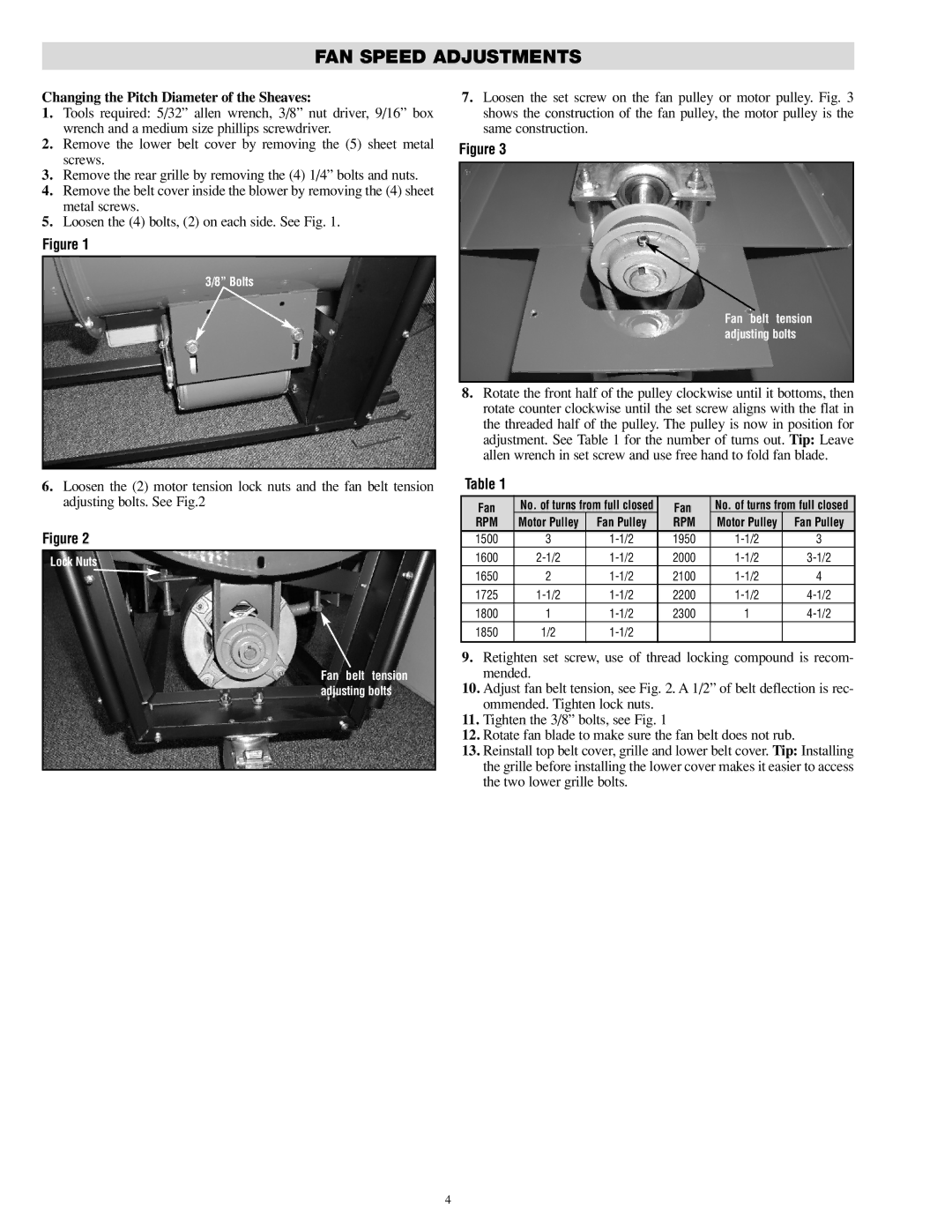

7.Loosen the set screw on the fan pulley or motor pulley. Fig. 3 shows the construction of the fan pulley, the motor pulley is the same construction.

Figure 3

Fan belt tension adjusting bolts

8.Rotate the front half of the pulley clockwise until it bottoms, then rotate counter clockwise until the set screw aligns with the flat in the threaded half of the pulley. The pulley is now in position for adjustment. See Table 1 for the number of turns out. Tip: Leave allen wrench in set screw and use free hand to fold fan blade.

Table 1

Fan | No. of turns from full closed | Fan | No. of turns from full closed | ||

RPM | Motor Pulley | Fan Pulley | RPM | Motor Pulley | Fan Pulley |

1500 | 3 | 1950 | 3 | ||

1600 | 2000 | ||||

1650 | 2 | 2100 | 4 | ||

1725 | 2200 | ||||

1800 | 1 | 2300 | 1 | ||

1850 | 1/2 |

|

|

| |

9.Retighten set screw, use of thread locking compound is recom- mended.

10.Adjust fan belt tension, see Fig. 2. A 1/2” of belt deflection is rec- ommended. Tighten lock nuts.

11.Tighten the 3/8” bolts, see Fig. 1

12.Rotate fan blade to make sure the fan belt does not rub.

13.Reinstall top belt cover, grille and lower belt cover. Tip: Installing the grille before installing the lower cover makes it easier to access the two lower grille bolts.

4