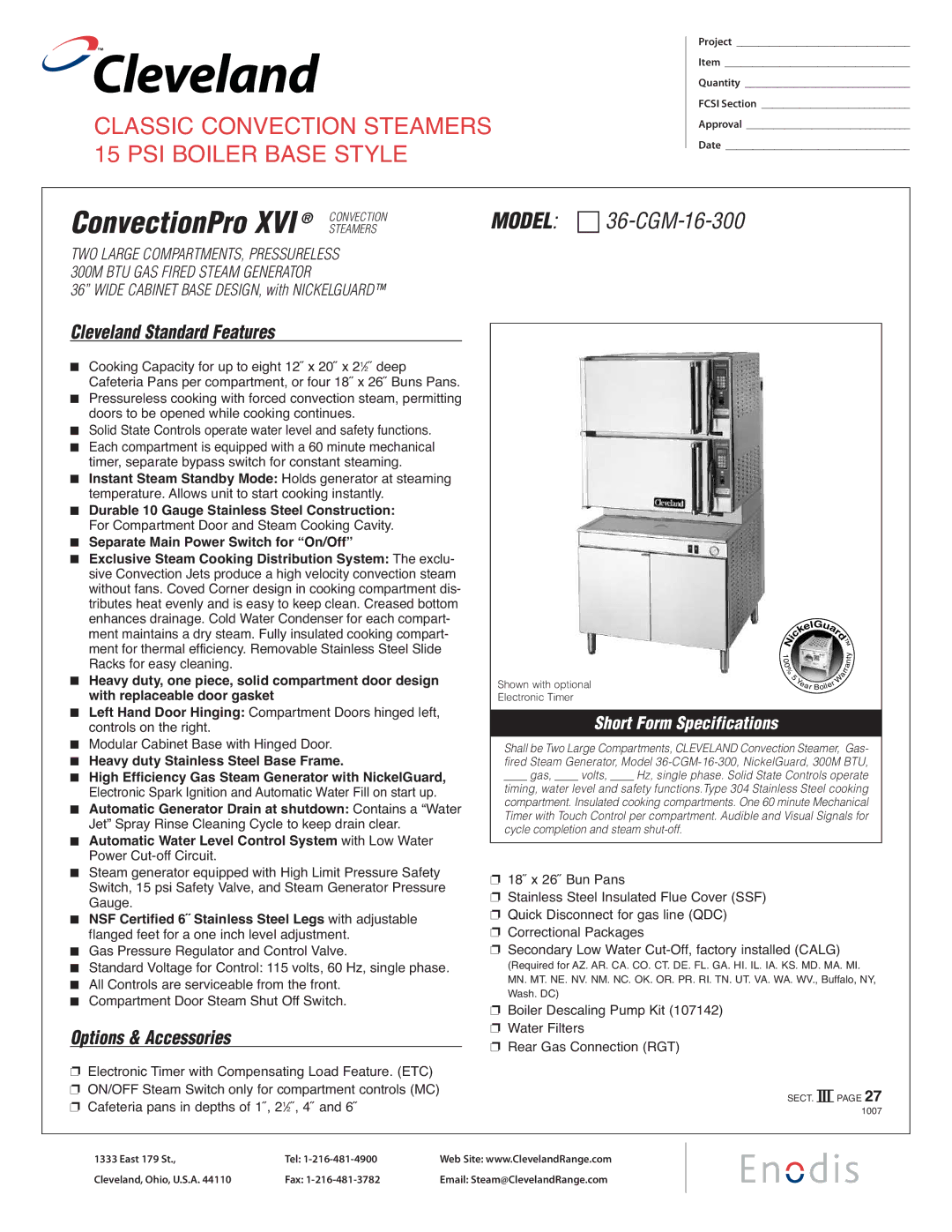

36-CGM-16-300 specifications

The Cleveland Range 36-CGM-16-300 is a standout model in the realm of commercial cooking equipment, specifically designed for professional kitchens seeking efficiency, durability, and versatility. This gas-powered steam kettle is a powerful solution for a variety of cooking needs, making it an essential tool for chefs who demand top-quality performance.One of the main features of the Cleveland Range 36-CGM-16-300 is its robust construction. Built with stainless steel, it is not only resistant to rust and corrosion but also easy to clean—a vital aspect for high-volume kitchens. With a 30-gallon capacity, this steam kettle is ideal for preparing large batches of soups, sauces, and stews, catering effortlessly to the demands of busy dining services.

The 36-CGM-16-300 incorporates innovative cooking technologies that enhance its functionality. Featuring direct steam injection, this unit allows for precise temperature control, ensuring that food is cooked evenly and efficiently. The steam jacket design delivers consistent heat distribution while minimizing heat loss, which improves energy efficiency and reduces cooking times.

Ergonomically designed, the Cleveland Range 36-CGM-16-300 is equipped with a tilt mechanism that allows for easy pouring and serving of contents. This feature not only saves time but also enhances safety by reducing the risk of spills. The kettle also includes an adjustable pilot light, which provides instant feedback on the burner status.

Additionally, the steam kettle includes an integrated drain, making not only the cooking process more convenient but also cleanup simple and quick. This is vital for maintaining a fast-paced kitchen environment where every second counts.

Furthermore, the 36-CGM-16-300 operates on natural gas, a fuel source that is widely preferred for its efficiency and cost-effectiveness in professional settings. The manual control valves facilitate straightforward operation of the gas burners, allowing chefs to tailor their cooking experience based on specific requirements.

In conclusion, the Cleveland Range 36-CGM-16-300 is a highly versatile, durable, and efficient cooking solution. Its blend of innovative technology and practical features sets it apart in the competitive market of commercial kitchen equipment, making it an essential tool for culinary professionals who strive to achieve excellence in their cooking endeavors.