APPLICATIONS

(Use only for the purposes listed below)

•Sanding on wood surfaces.

•Removing rust from and sanding steel surfaces.

SANDING DISC SELECTION

Selecting the correct size grit and type sanding disc is an extremely important step in achieving a high quality sanded finish. Aluminum oxide, silicon carbide, and other synthetic abrasives are best for power sanding. Natural abrasives, such as flint and garnet are too soft for economical use in power sanding.

In general, coarse grit will remove the most material and finer grit will produce the best finish in all sanding operations. The condition of the surface to be sanded will determine which grit will do the job. If the surface is rough, start with a coarse grit and sand until the surface is uniform. Medium grit may then be used to remove scratches left by the coarser grit and finer grit used for finishing of the surface. Always continue sanding with each grit until surface is uniform.

,_ WARNING: | Your sander should never be | |

n |

|

|

connected to power supply when you are | ||

assembling | parts, | making adjustments, |

assembling or replacing sanding disc, cleaning, | ||

or when not in use. Disconnecting your sander | ||

will prevent accidental starting that could cause | ||

serious personal | injury. | |

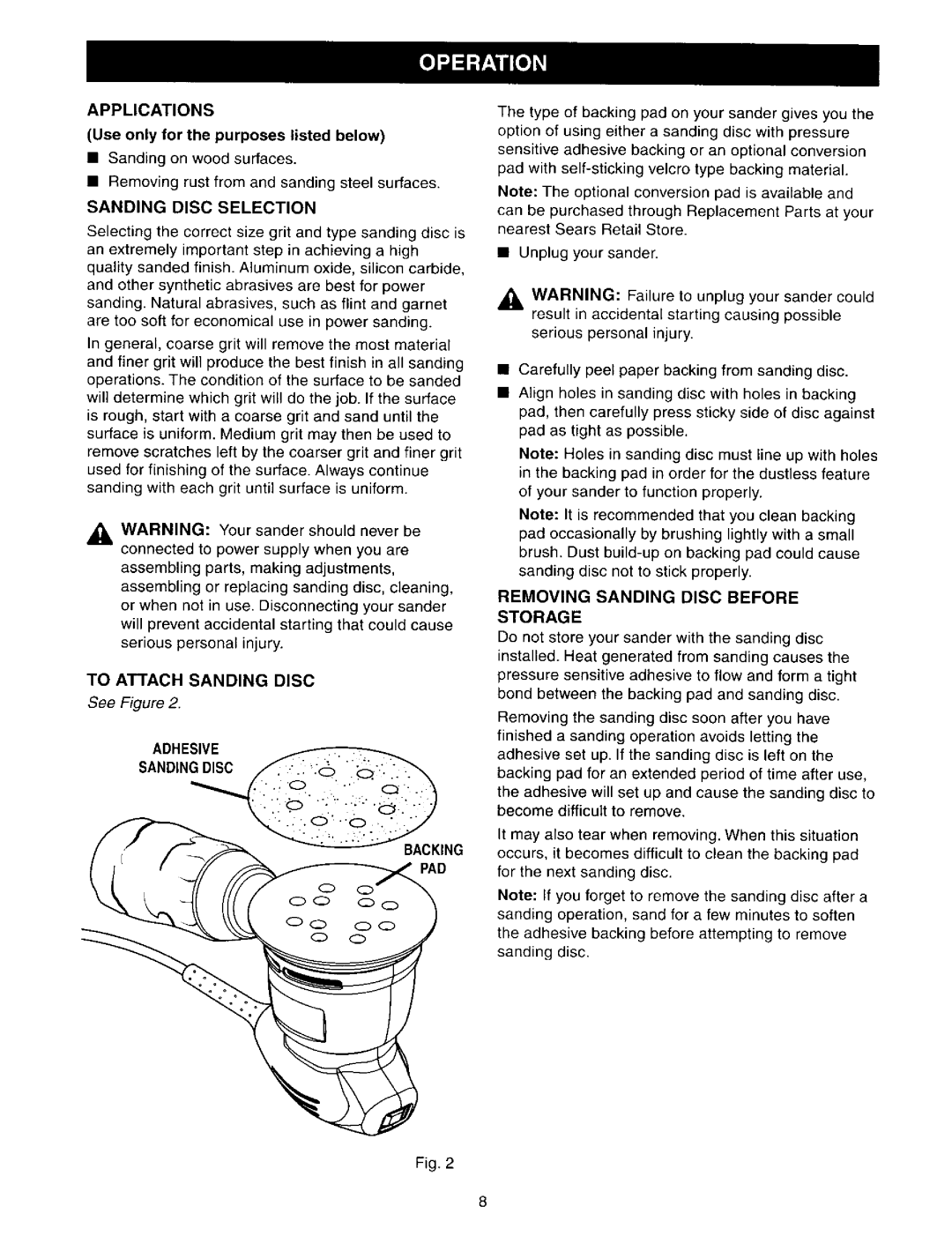

TO ATTACH SANDING DISC

See Figure 2.

ADHESIVE

BACKING

PAD

Fig. 2

The type of backing pad on your sander gives you the option of using either a sanding disc with pressure sensitive adhesive backing or an optional conversion pad with

Note: The optional conversion pad is available and can be purchased through Replacement Parts at your nearest Sears Retail Store.

•Unplug your sander.

_1= WARNING: Failure to unplug your sander could

result in accidental starting causing possible serious personal injury.

Carefully peel paper backing from sanding disc.

Align holes in sanding disc with holes in backing pad, then carefully press sticky side of disc against pad as tight as possible.

Note: Holes in sanding disc must line up with holes in the backing pad in order for the dustless feature of your sander to function properly.

Note: It is recommended that you clean backing pad occasionally by brushing lightly with a small brush. Dust

REMOVING SANDING DISC BEFORE

STORAGE

Do not store your sander with the sanding disc installed. Heat generated from sanding causes the pressure sensitive adhesive to flow and form a tight bond between the backing pad and sanding disc.

Removing the sanding disc soon after you have finished a sanding operation avoids letting the adhesive set up. If the sanding disc is left on the backing pad for an extended period of time after use,

the adhesive will set up and cause the sanding disc to become difficult to remove.

It may also tear when removing. When this situation occurs, it becomes difficult to clean the backing pad for the next sanding disc.

Note: If you forget to remove the sanding disc after a sanding operation, sand for a few minutes to soften the adhesive backing before attempting to remove sanding disc.

8