Do not force. The weight of the unit supplies ad- equate pressure, so let the sanding disc and sander do the work. Applying additional pressure only slows the motor, rapidly wears sanding disc and greatly reduces sander speed. Excessive pressure will overload the motor causing possible damage from motor overheating and can result in inferior work. Any finish or resin on wood may soften from the frictional heat. Do not allow sanding on one spot too long as the sander's rapid action may remove too much material, making the surface uneven.

Extended periods of sanding may tend to overheat the motor. If this occurs, turn sander off and wait until sanding disc comes to a complete stop, then remove it from workpiece. Remove your hand from vent area, remove sanding disc, then with your hand removed from vent area, turn sander on and run it free without a load to cool motor.

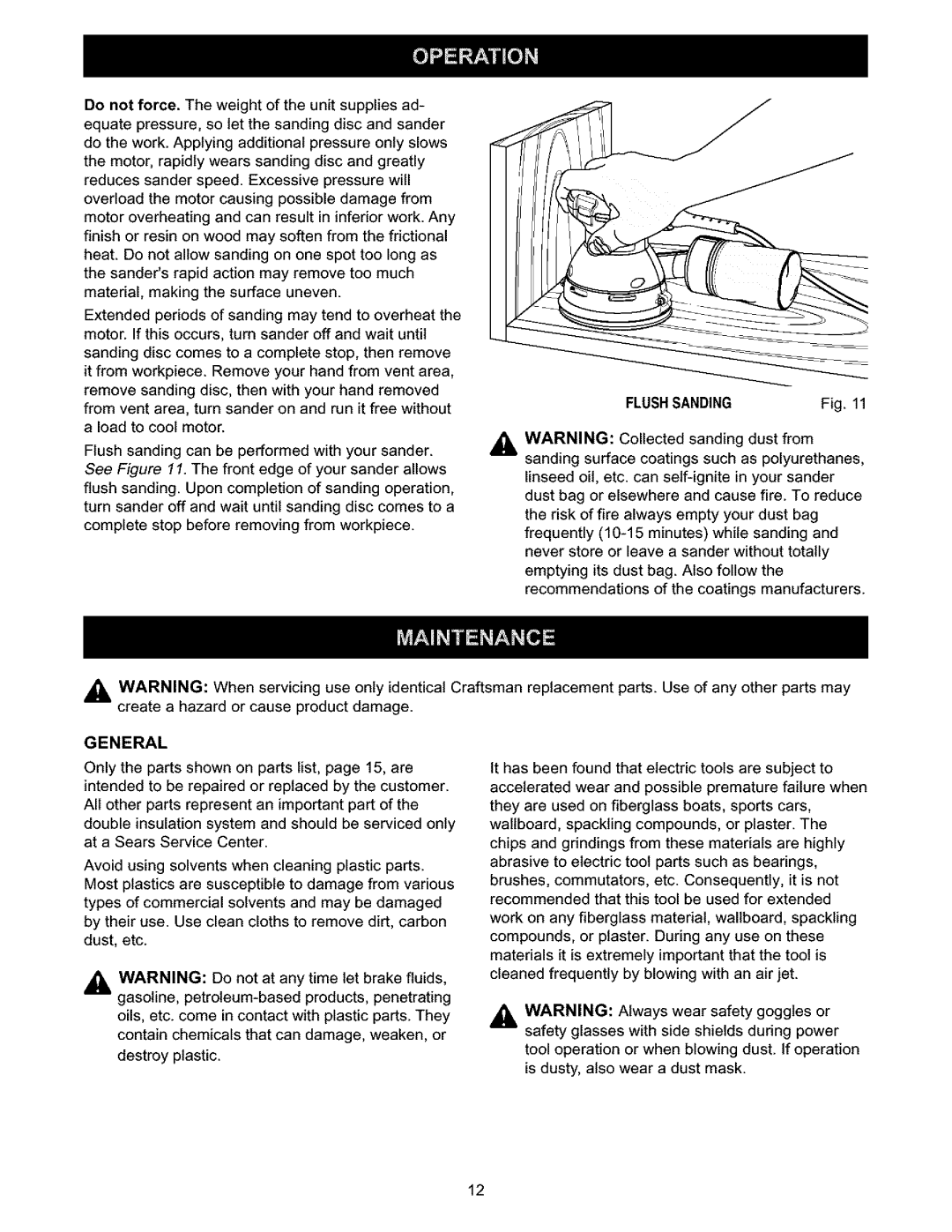

Flush sanding can be performed with your sander. See Figure 11. The front edge of your sander allows flush sanding. Upon completion of sanding operation, turn sander off and wait until sanding disc comes to a complete stop before removing from workpiece.

FLUSHSANDINGFig. 11

,& WARNING: Collected sanding dust from sanding surface coatings such as polyurethanes, linseed oil, etc. can

,_ WARNING: When servicing use only identical Craftsman replacement parts. Use of any other parts may create a hazard or cause product damage.

GENERAL

Only the parts shown on parts list, page 15, are intended to be repaired or replaced by the customer. All other parts represent an important part of the double insulation system and should be serviced only at a Sears Service Center.

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, carbon dust, etc.

_ WARNING: Do not at any time let brake fluids, gasoline,

oils, etc. come in contact with plastic parts. They contain chemicals that can damage, weaken, or destroy plastic.

It has been found that electric tools are subject to accelerated wear and possible premature failure when they are used on fiberglass boats, sports cars, wallboard, spackling compounds, or plaster. The chips and grindings from these materials are highly abrasive to electric toot parts such as bearings,

brushes, commutators, etc. Consequently, it is not recommended that this tool be used for extended

work on any fiberglass material, wallboard, spackling compounds, or plaster. During any use on these materials it is extremely important that the tool is cleaned frequently by blowing with an air jet.

_ WARNING: Always wear safety goggles or safety glasses with side shields during power

tool operation or when blowing dust. If operation is dusty, also wear a dust mask.

12