Craftsman

Rotary Power

Too

The Rotary Toot is a handful of

polisher, sander, cutter, power brush, drilt and more

The Rotary Tool has a small, powerful electric

motor, is comfortable in the hand, and is

made to accept a targe variety of accessories including abrasive wheels, drill bits, wire brushes, polishers, engraving cutters, router bits, and cutting wheels Accessories come in a variety of shapes and permit you to do a number of different jobs. As you become familiar with the range of accessories and their uses, you will learn ust how versatile the Rotary Tool is You f see dozens of uses you hadn'tthought of before now

The real secret of the Rotary Tool is its speed To understand the advantages of its high speed, you have to know that the standard portable electric dril runs at speeds up to 2,800 revolutions per minute. The Rotary Tool operates at speeds up to 30,000 revolutions per minute The typical electdc drill is a low- speed, high torque too!; the Rotary Tool is ust

the opposite - a

high speed tools, the speed combined with the accessory mounted in the collet does the work. You don'tappty pressure to the tool, but simply hold and gu{de it tn the low speed tools, you not only guide the tool, but also apply pressure to it, as you do, for example, when drilling a hole

It is this high speed, along with its compact size and wide variety of special accessories, that makes the Rotary Tool different from other power tools The speed enables it to do jobs low speed tools cannot do, such as culling hardened steel, engraving gtass, etc

Getting the most out of your Rotary Tool is a ma_ter of learning how to let this speed work for you

Using the

Rotary Power

TooN

Read the next sections carefully They will hetp you use your Rotary Tool correctly and hetp you select the correct accessory for your job

.... The first step in learning to use the Rotary

Tool is to get the "feel" of it Hold it in your hand and feel its weight and balance. Feel the taper of the housing This taper permits the Rotary Tool to be grasped much like a pen or pencil

When you turn on the tool for the first time, hold it away from your face. Accessories can be damaged during handling, and can fly apart as they come up to speed This is net common, but it does happen

Practice on scrap materials first to see how the Rotary Tool cuts Keep in mind that the work is done by the speed of the tool and by the accessory in the coltet. You should not tean on or push the tool into the work

Instead, lower the spinning accessory lightly to the work and allow it to touch the point at which you want cutting (or sanding or etching, etc ) to begin, Concentrate on guiding the tool over the work using very little pressure from your hand Aitow the accessory to do the work

Usually, it is best to make a series of passes with the tool rather than attempt to do alt the work in one pass To make a cut, for example, pass the tool back and forth over the work, much as you would a small paint brush Cut a little material on each pass until you reach the desired depth, For most work, the deft, gentle touch is best With it, you have the best control, are less likely to make errors, and will get the most efficient work out of the accessory

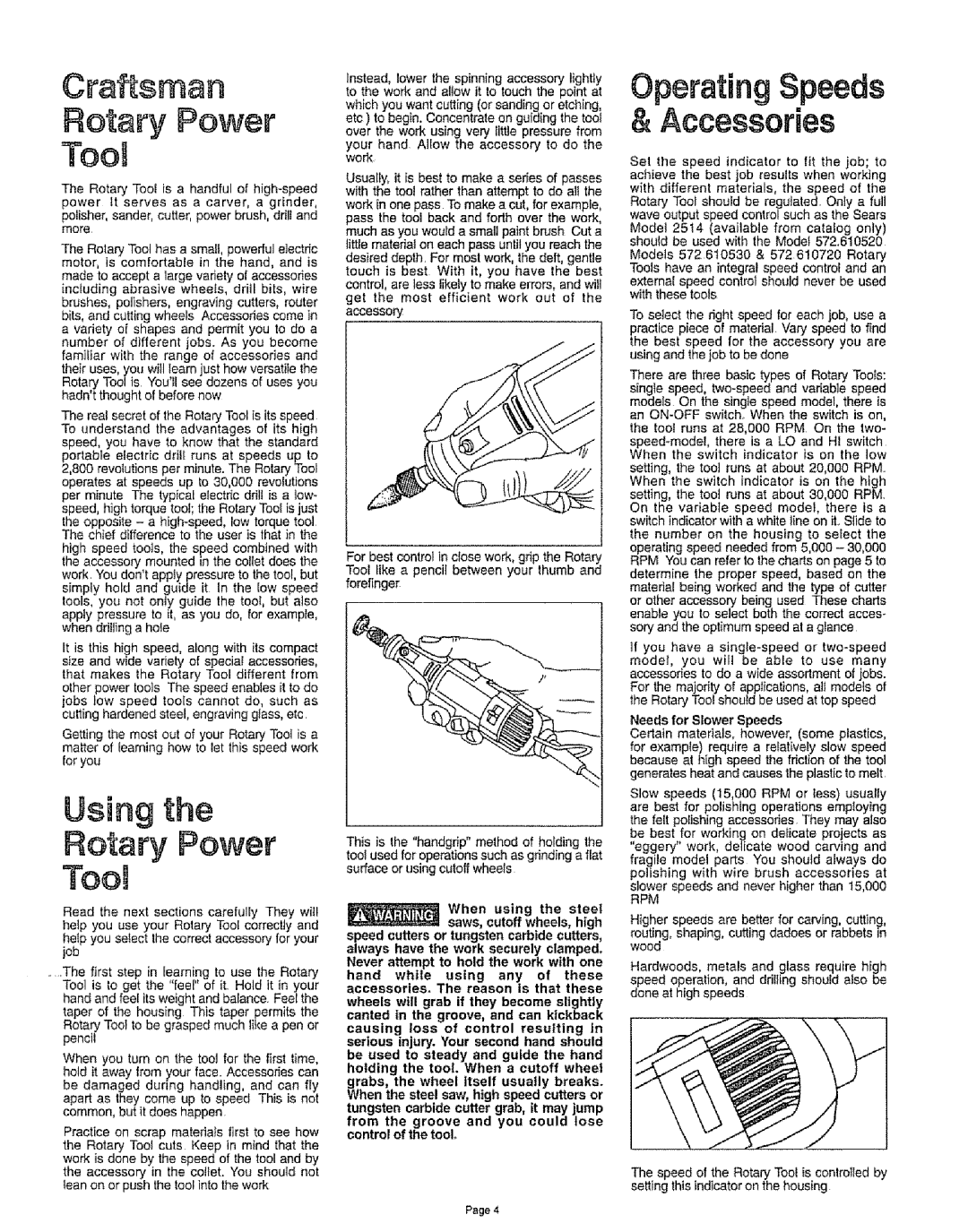

For best control in close work, grip the Rotary Tool fike a pencil between your thumb and forefinge_

This is the "handgrip" method of holding the tool used for operationssuch as grinding a flat surface or using cutoff wheels

_When using the steel saws, cutoff wheels, high

speed cutters or tungsten carbide cutters, always have the work securely clamped.

Never attempt to hold the work with one hand while using any of these accessories. The reason is that these wheels will grab if they become slightly canted in the groove, and can kickback causing loss of control resulting in serious injury. Your second hand should be used to steady and guide the hand holding the tool. When a cutoff wheel grabs, the wheel itself usually breaks.

When the steel saw, high speed cutters or tungsten carbide cutter grab, it may jump

from the groove and you could lose control of the tool.

Operating Speeds & Accessories

Set the speed indicator to fit the job; to achieve the best job results when working with different materials, the speed of the Rotary Too_ should be regulated. Only a full wave output speed control such as the Sears

Model 2514 (available from catalog only) shoutd be used with the Modet 572.610520

Models 572610530 & 572610720 Rotary Tools have an integral speed control and an

external speed control should never be used with these tools

To select the right speed for each job, use a practice piece of material. Vary speed to find the best speed for the accessory you are using and the job to be done

There are three basic types of Rotary Tools: singte speed,

setting, the too] runs at about 20,000 RPM When the switch indicator is on the high setting, the toot runs at about 30,000 RPM On the variable speed model, there is a switch indicator with a white line on it..Slide to

the number on the housing to seiect the operating speed needed from 5,000 - 30,000 RPM You can refer to the charts on page 5 to determine the proper speed, based on the material being worked and the type of cutter or other accessory being used These charts enable you to select both the correct acces- sory and the optimum speed at a glance

If you have a

Needs for Slower Speeds

Certain materials, however, (some plastics, for example) require a retatively slow speed because at high spend the friction of the tool generates heat and causes the plastic to melt

Slow speeds (15,000 RPM or less) usually are best for polishing operations employing the felt polishing accessories They may also be best for working on de_icate projects as "eggery" work, delicate wood carving and fragile model parts You should always do

polishing with wire brush accessories at

slower speeds and never higher than 15,000

RPM

Higher speeds are better for carving, cutting,

routing, shaping, cutting dadoes or rabbets in wood

Hardwoods, metals and glass require high speed operation, and drilling should also be done at high speeds

The speed of the Rotary Tool is controlted by setting this indicator on the housing

Page 4