TheSettingsforApproximateRevolutionsPer MinuteRotaryTooiVariableSpeedModel 572610530

SwitchSetting Speed Range

1 4,500- 8,000 RPM

2

312,000- t7,000 RPM

418,000 - 24,000 RPM

525,000 - 30,000 RPM

NOTE: Speed is affected by voltage changes. A reduced incoming voltage will slow the RPM of the toot, especially at the lowest setting, If your tool appears to be

running slowly increase the speed setting accordingly°

The point to remember is this: You can do the great majorily of work with the single speed at its regular speed of 28,000 RPM But for certain materials and types of work, you need slower speeds

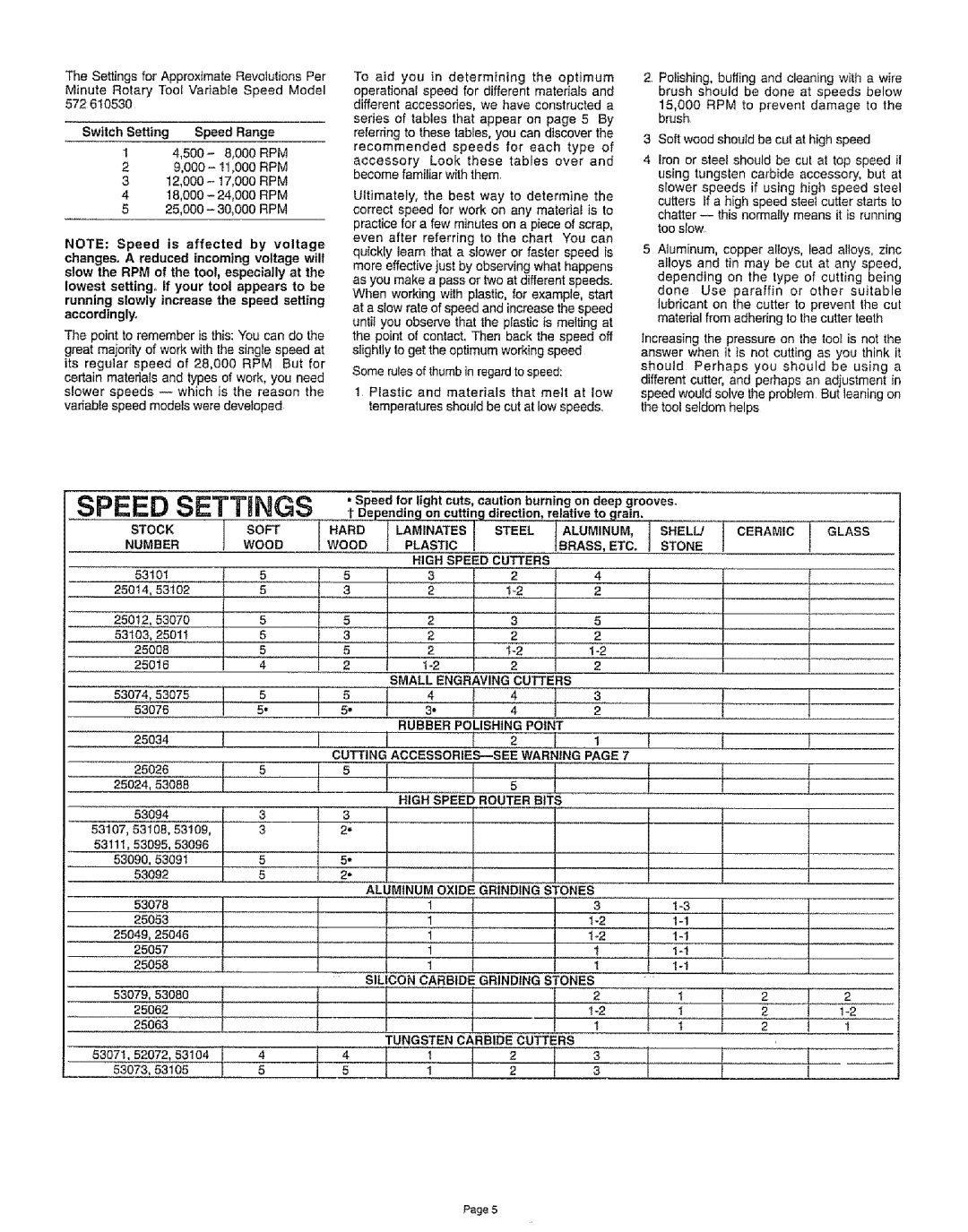

To aid you in determining the optimum operational speed for different materials and different accessories, we have constructed a

series of tables that appear on page 5 By referring to these tables, you can discover the recommended speeds for each type of accessory Look these tables over and become familiar with them.

Ultimately, the best way to determine the correct speed for work on any matedal is to practice for a few minutes on a piece of scrap, even after referring to the chart You can

quickly learn that a slower or faster speed is more effective just by observing what happens

as you make a pass or two at different speeds. When working wilh plastic, for example, start at a slow rate of speed and increase the speed untit you observe that the plastic is melting at the point of contact. Then back the speed off slightly to get the optimum working speed

Some rulesof thumbin regardto speed:

1 Plastic and materials that melt at low temperatures should be cut at low speeds.

2, Polishing, buffing and cleaning with a wire brush should be done at speeds below

15,000 RPM to prevent damage to the brush

3Soft wood shoutd be cut at high speed

4iron or steel should be cut at top speed il using tungsten carbide accessory, but at slower speeds if using high speed steel cutters If a high speed steel cutter starts to chatter

5Aluminum, copper aIfoys, lead alloys, zinc alloys and tin may be cut at any speed, depending on the type of cutting being done Use paraffin or other suitable lubricant on the cutter to prevent the cut material from adhering to the cutter teeth

Increasing the pressure on the too_is not the answer when it is not cutting as you think it should Perhaps you should be using a different cutter, and perhaps an adjustment in speed would solve the problem But leaning on the tool seldom helps

SPEED SETTINGS

| STOCK | I | SOFT |

| NUMBER | J | WOOD |

| 53101 |

| 6 |

|

| 5 | |

|

|

| |

...... | 25014,53102 |

|

|

| 25012,53070 |

| 5 |

I | 53103,25011 |

| 6 |

|

|

| 5 |

............................... | 2501625008 |

| 4 |

.Spee,I for light cuts, caution burning on deep grooves. ,t Dope _din 9 on cutting direction, relative to £1rain.

HARD | LAMINATES1STEELpLASTIC |

| GLASSBRASSALUMINUM'ETC. ] SHELL]STONE | l CERAMIC 1 |

WOOD |

| |||

| HIGH SPEED | CUTTERS |

|

|

5 | 3 | 2 |

|

|

| 2 | I:2 |

|

|

5 | 2 | 3 | 5 |

|

5 | 2 |

| ||

3 | .............. 2 | 2 | 2 |

|

2 | 2 | 2 |

|

|

|

|

| 5 | SMALLENGRAWNGCUTTERS | J |

| ] | ||||

53074,53075 | } | 5 |

| 4 | f | 4 | i | 3 |

| |||

| 5, | 3" | I | 4 |

| 2 |

| |||||

53075 |

| 5• |

|

|

| |||||||

|

|

|

|

| RUBBER | POLISHING | POINT |

|

|

|

| |

25034 | [ |

|

|

| I | I | 2 | I, | 1 |

| I |

|

|

|

|

| CUTTING | t |

|

| |||||

25026 | I | 5 | l | 5 |

|

| 6 | i |

| J | ] | |

|

|

| i | |||||||||

25024, 53088 |

|

|

|

|

|

| ||||||

53094 |

|

|

|

| HIGHSPEEDROUTERBITS |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| |

53107,53108,53!09, |

|

|

| 2" |

|

|

|

|

|

|

|

|

53111,53095,53096 |

|

|

|

|

|

|

|

|

|

|

|

|

53090,53091 |

| 5, |

|

|

|

|

|

|

|

|

|

53092 |

|

|

|

|

|

|

|

|

|

|

|

|

| ] | ALUMINUM OXIDE | GRINDING | STONES |

|

|

|

| ||

25053 |

| : | 1 | j |

|

| 3 |

| I | ||

[ | i |

|

|

|

|

| |||||

53078 |

|

|

|

|

|

|

|

| |||

25049,25046 |

|

|

|

|

|

|

|

|

| ||

|

| J |

| 1 | 1 |

|

|

|

| ||

|

|

|

|

|

|

| |||||

|

| t | 1t |

|

|

| 1I |

| b | ||

2505825057 | ,, | t |

|

| ! | ||||||

|

|

| SILICON | CARBIDE | GRINDING | STONES | 1 | I | t | 2 | |

|

|

|

|

| 1 | I | |||||

|

|

|

|

|

|

|

|

|

| 1 | 2 |

53079,530802506325062I |

|

|

|

|

|

|

|

| 2 | ||

|

|

|

|

|

|

|

|

|

| ||

|

| J 5 | TUNGSTEN | CARBIDE CUTTERS |

| t |

|

| |||

|

|

|

|

|

|

|

|

|

| ||

63071,52072,5310453073,53105 | I |

| 1 |

| 2 | I | 3 | L |

| f | |

t 1

J

Page 5