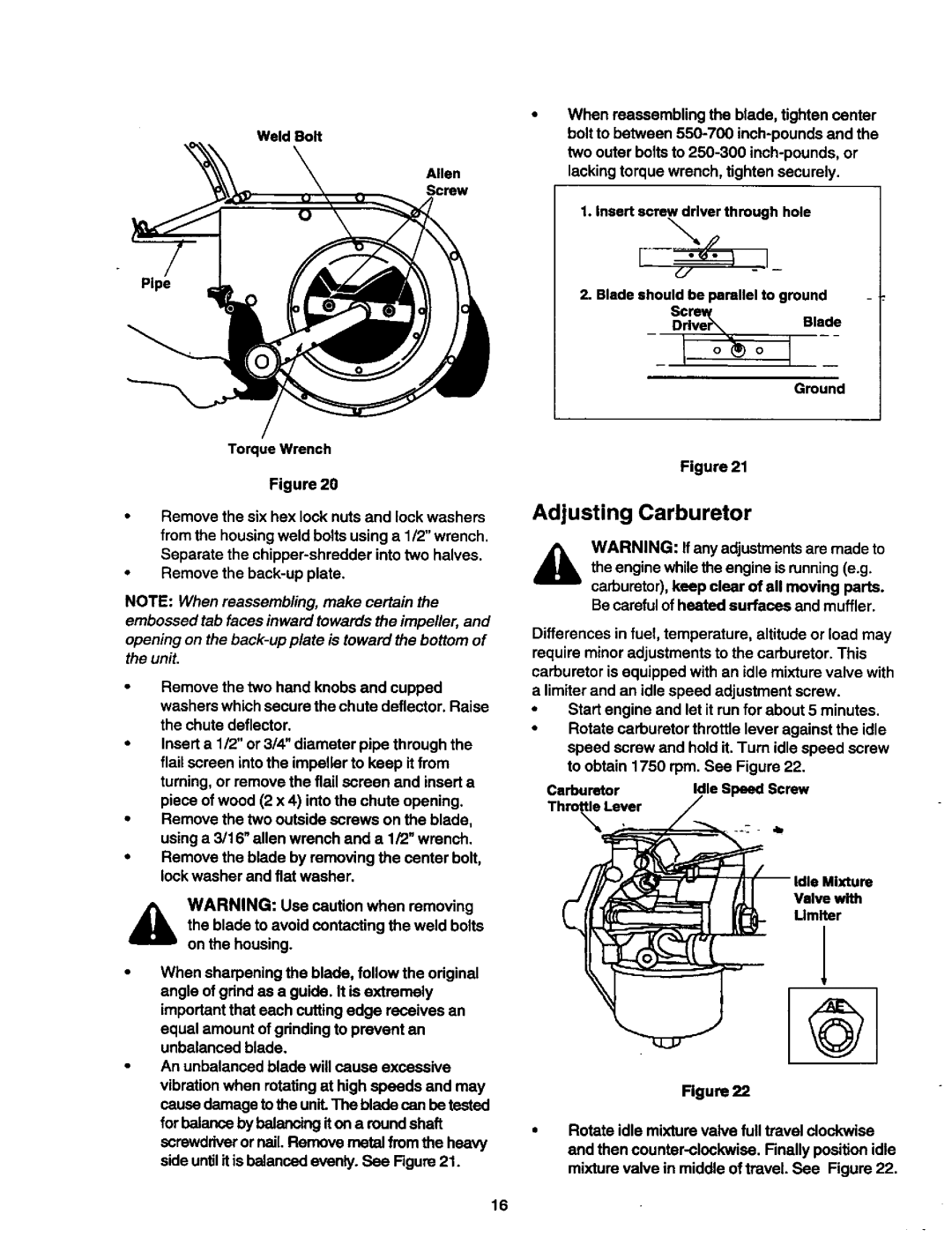

Weld Bolt

Allen

Screw

Pipe

Torque Wrench

Figure 20

•Remove the six hex lock nuts and lock washers from the housing weld bolts using a 112"wrench. Separate the

•Remove the

NOTE: When reassembling, make certain the embossed tab faces inward towards the impeller, and

opening on the

•Remove the two hand knobs and cupped washers which secure the chute deflector. Raise the chute deflector,

•Insert a 112"or 314"diameter pipe through the flail screen into the impeller to keep it from turning, or remove the flail screen and insert a piece of wood (2 x 4) into the chute opening.

•Remove the two outside screws on the blade, using a 3116"allen wrench and a 1/2" wrench,

•Remove the blade by removing the center bolt, lock washer and flat washer.

the blade to avoid contacting the weld bolts

WARNING: Use caution when removing on the housing.

When sharpening the blade, follow the odginal angle of grind as a guide. It is extremely important that each cutting edge receives an

equal amount of grinding to prevent an unbalanced blade.

An unbalanced blade will cause excessive

vibration when rotating at high speeds and may cause damage to the unit.The blade can be tested for balance by balancing iton a round shaft screwdriveror nail. Remove metal from the heavy side untilitis balanced evenly. See Figure 21.

When reassembling the blade, tighten center bolt to between

1. Insert screw driver through hole

2.Blade should be parallel to ground Sc

D:d_e_Blade

I I-

Ground

Figure 21

Adjusting Carburetor

WARNING: If any adjustments are made to the engine while the engine is running (e.g. carburetor), keep clear of all moving parts. Be careful of heated surfaces and muffler.

Differences in fuel, temperature, altitude or load may require minor adjustments to the carburetor. This carburetor is equipped with an idle mixture valve with a limiter and an idle speed adjustment screw.

•Start engine and let it run for about 5 minutes.

•Rotate carburetor throttle lever against the idle speed screw and hold it. Turn idle speed screw to obtain 1750 rpm. See Figure 22.

Carburetor | Idle Speed Screw |

Thro_ Lever

@

Figure 22

Rotate idle mixture valve full travel clockwise and then

16