_R

Always observe safety rules when

performing any maintenance.

BRAKE OPERATION

If tractor requires more than six (6) feet stopping distance at high speed in highest

gear, then brake must be adjusted. (See "TO ADJUST BRAKE in the Service and

Adjustments section of this manual),

TIRES

•Maintain proper air pressure in all tires (See "PRODUCT SPECIFICATIONS" section of this manual).

•Keep tires free of gasoline, oil, or insect contmt chemicals which can harm rubber.

•Avoid stumps, stones, deep ruts, sharp objects and other hazards that may cause tire damage.

NOTE: To seastire punctures and prevent flat tires due to slow leaks, tire sealant may

be purchesed from your local parts dealer.

Tire sealant also prevents tire dry rot and corrosion.

OPERATOR PRESENCE SYSTEM

Be sure operator presence and intedock

systems are working properly. If your tractor does not function as described,

repair the problem immediately.

•The engine should not start unless the clutch/brake pedal is fully depressed and attechement clutch control is in the

disengaged position.

•When the engine is running, any attempt by the operator to leave the seat without first setting the parking brake shouSd shut off the engine.

•When the engine is running and the attachment clutch is engaged, any attempt by the operator to leave the seat sho_k:lshut off the engine.

•The attachment clutch should never

operate unless the operator is in the seat.

BLADE CARE

Far best results mower blades must be

kept sharp. Replace bent or damaged blades.

BLADE REMOVAL

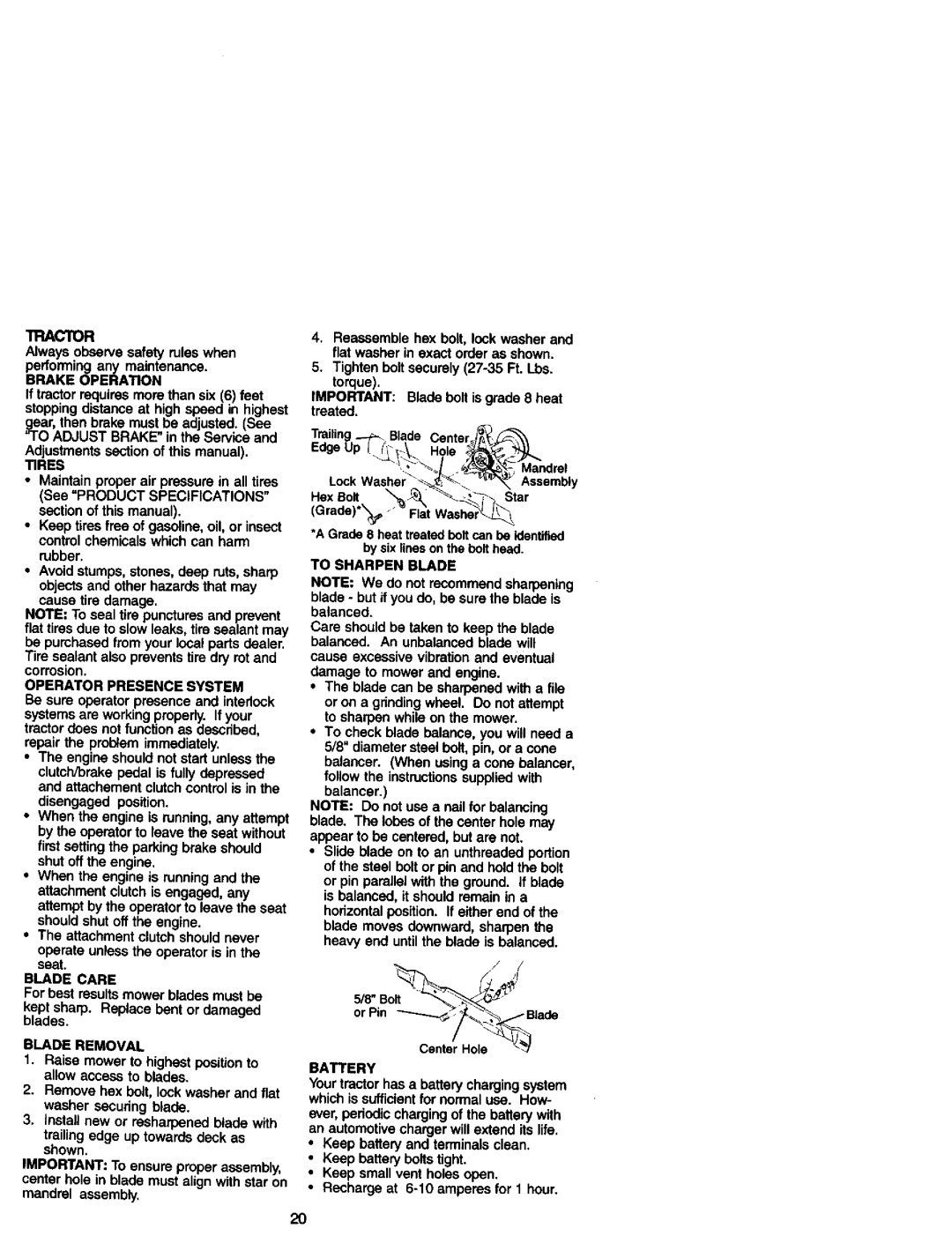

I.Raise mower to highest position to a$$owaccess to blades.

2.Remove hex bolt, lock washer and flat washer securing blade.

3.install new or resharpened blade with

trailing edge up towards deck as

Shown.

IMPORTANT: To ensure proper assembly, center hole in blade must align with star on mandrel assembly.

4, Reassemble hex bolt, lock washer and fiat washer in exact order as shown.

5.Tighten bolt securely

IMPORTANT: Blade bolt is grade 8 heat treated.

Trailing_ Blade Center.J_

Edge Up ((/_.\ | Hole _ | _'_ |

Lock Washer "_'_ =_'_ Assembly

Hex Bolt | "_ | Star | |

(Grade)*'_ | Flat Washer/_ |

|

*A Grade 8 heat treatedbolt can be identified by six lineson the bolt head.

TO SHARPEN BLADE

NOTE: We do not recommend sharpening

blade - but if you do, be sure the blade is balanced.

Care should be taken to keep the blade balanced. An unbalanced blade will

cause excessNe vibration and eventual damage to mower and engine.

•The blade can be sharpened with a file or on a gdnding wheel. Do not attempt to sharpen while on the mower.

•To check blade balance, you will need a 5/8" diameter steel bolt, pin, or a cone balancer. (When using a cone balancer, follow the instructions supplied with

balancer.)

NOTE: Do not use a nail for balancing blade. The lobes of the center hole may

appear to be centered, but are not.

•Slide blade on to an unthreaded portion of the steel bolt or pin and hold the bolt or pin parallel with the ground. If blade is balanced, it should remain in a hodzontal position. If either end of the bSede moves downward, sharpen the heavy end until the blade is balanced.

/

5/8" Bolt or Pin

Center Hole

BATTERY

Your tractor has a batterycharging system which is sufficient for normal use. How-

ever, pedndic charging of the battery with an automotive charger will extend its life.

•Keep battery and terminals clean.

•Keep battery botts tight.

•Keep small vent holes open.

•Recharge at

2O