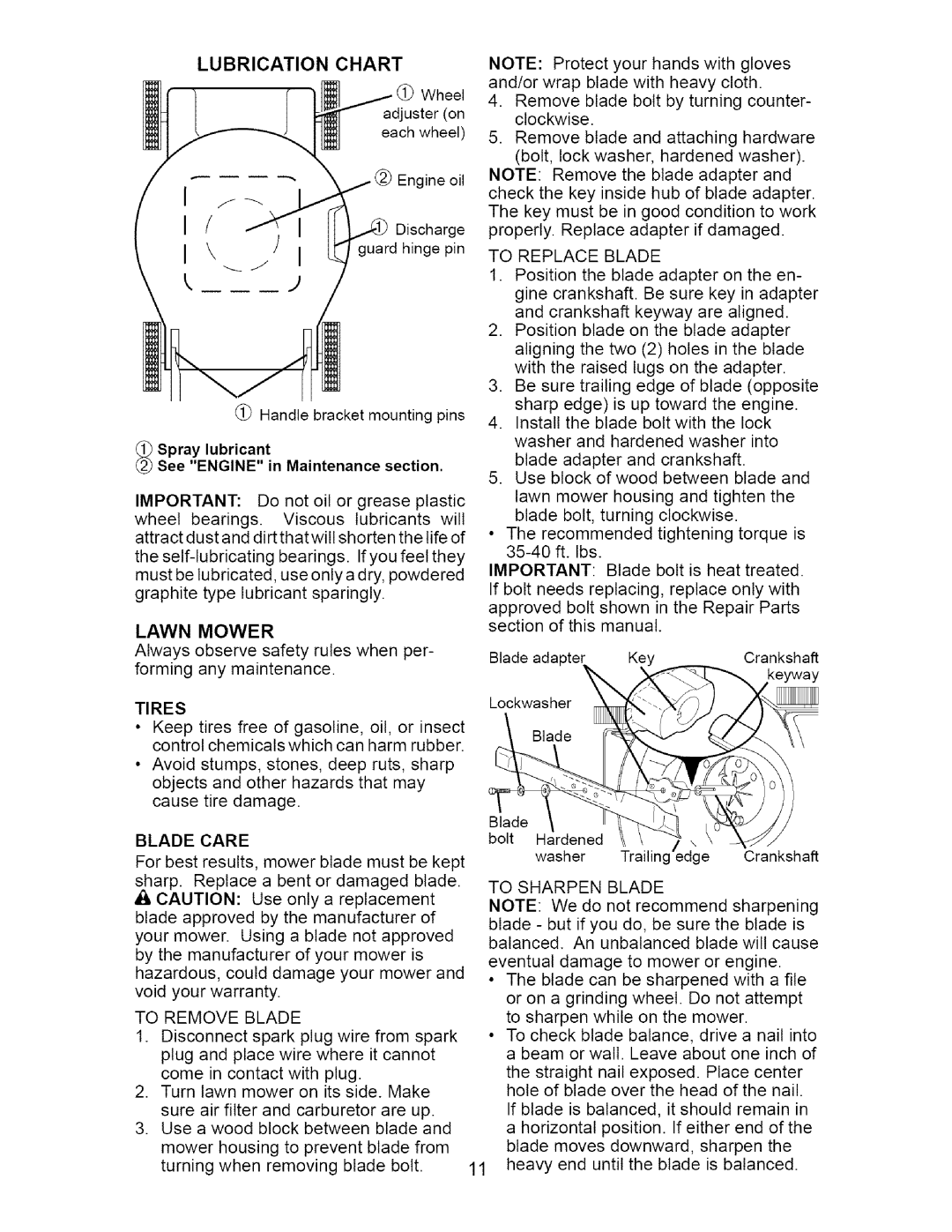

LUBRICATION CHART

Wheel

adjuster (on each wheel)

Handle bracket mounting pins

_ Spray lubricant

See "ENGINE" in Maintenance section.

IMPORTANT: Do not oil or grease plastic

wheel bearings. Viscous lubricants will attract dust and dirt that will shorten the life of

the

LAWN MOWER

Always observe safety rules when per- forming any maintenance.

TIRES

•Keep tires free of gasoline, oil, or insect control chemicals which can harm rubber.

•Avoid stumps, stones, deep ruts, sharp objects and other hazards that may cause tire damage.

BLADE CARE

For best results, mower blade must be kept sharp. Replace a bent or damaged blade.

_i, CAUTION: Use only a replacement blade approved by the manufacturer of your mower. Using a blade not approved by the manufacturer of your mower is hazardous, could damage your mower and void your warranty.

TO REMOVE BLADE

1.Disconnect spark plug wire from spark plug and place wire where it cannot come in contact with plug.

2.Turn lawn mower on its side. Make sure air filter and carburetor are up.

3.Use a wood block between blade and

mower housing to prevent blade from turning when removing blade bolt.

NOTE: Protect your hands with gloves and/or wrap blade with heavy cloth.

4.Remove blade bolt by turning counter- clockwise.

5.Remove blade and attaching hardware (bolt, lock washer, hardened washer).

NOTE: Remove the blade adapter and check the key inside hub of blade adapter. The key must be in good condition to work properly. Replace adapter if damaged.

TO REPLACE BLADE

1.Position the blade adapter on the en- gine crankshaft. Be sure key in adapter and crankshaft keyway are aligned.

2.Position blade on the blade adapter aligning the two (2) holes in the blade with the raised lugs on the adapter.

3.Be sure trailing edge of blade (opposite sharp edge) is up toward the engine.

4.Install the blade bolt with the lock washer and hardened washer into blade adapter and crankshaft.

5.Use block of wood between blade and

lawn mower housing and tighten the blade bolt, turning clockwise.

•The recommended tightening torque is

IMPORTANT: Blade bolt is heat treated.

If bolt needs replacing, replace only with approved bolt shown in the Repair Parts section of this manual.

Blade adapter | Key | Crankshaft |

Lockwasher _

i

bolt Hardened d'ge

washerCrankshaft

TO SHARPEN BLADE

NOTE: We do not recommend sharpening

blade - but if you do, be sure the blade is balanced. An unbalanced blade will cause

eventual damage to mower or engine.

•The blade can be sharpened with a file or on a grinding wheel. Do not attempt to sharpen while on the mower.

•To check blade balance, drive a nail into a beam or wall. Leave about one inch of

the straight nail exposed. Place center hole of blade over the head of the nail.

If blade is balanced, it should remain in a horizontal position. If either end of the

blade moves downward, sharpen the

11heavy end until the blade is balanced.